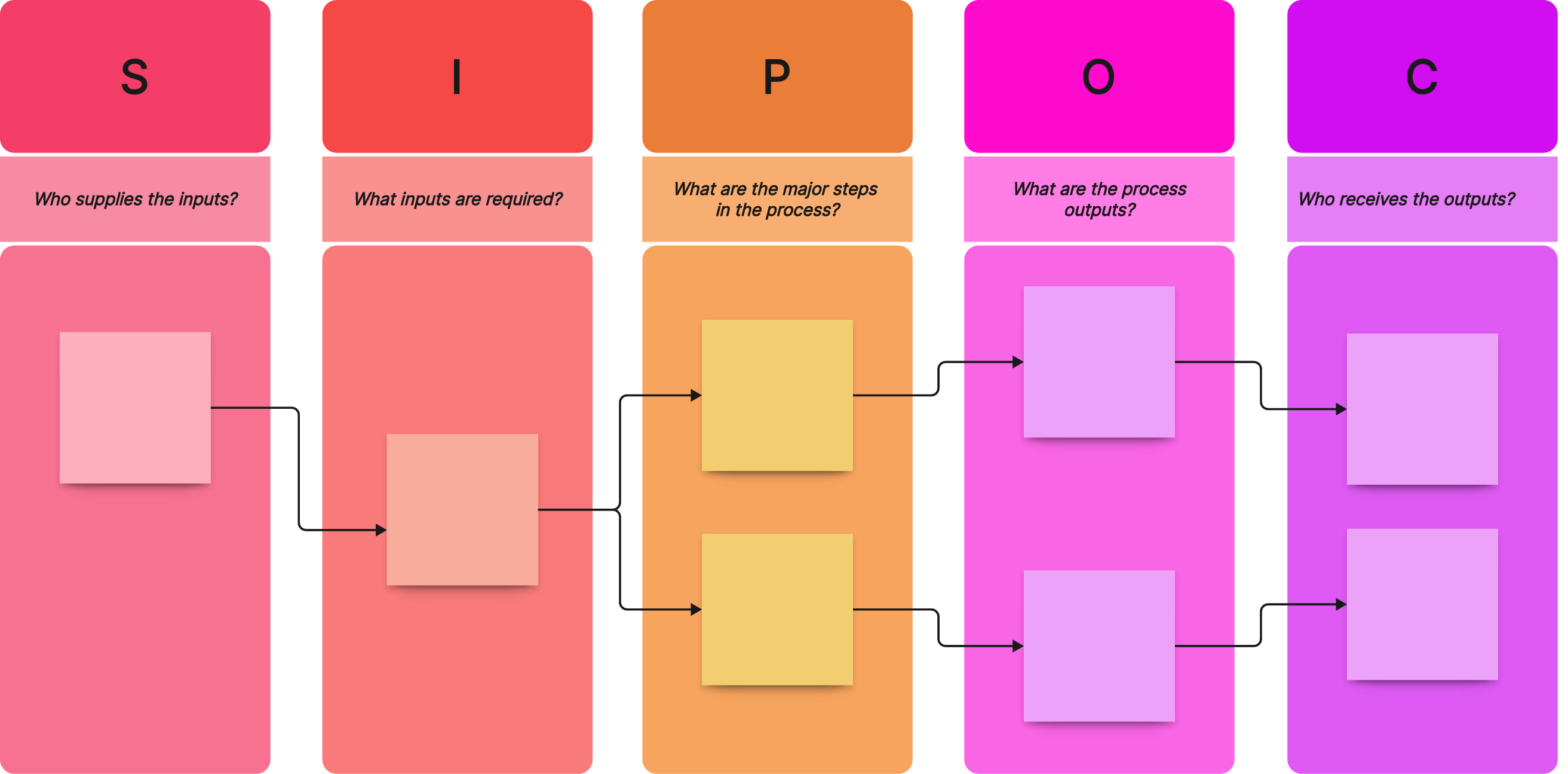

SIPOC diagrams are a visualization tool used in process improvement, especially in Six Sigma methodology. Standing for suppliers, inputs, processes, outputs, and customers, a SIPOC diagram gives a high-level snapshot of a process, detailing its key components. Originating from Total Quality Management, it's become an essential tool for many organizations. Let’s have a look at more details and examples of it.

What Is a SIPOC Diagram

A SIPOC diagram is a comprehensive visualization tool predominantly used in process improvement methodologies, particularly within Six Sigma. The acronym "SIPOC" stands for suppliers, inputs, processes, outputs, and customers.

The primary objective of the SIPOC diagram is to give stakeholders a high-level snapshot or overview of a particular process, ensuring clarity in understanding its essential components. By mapping out these five primary elements, organizations can efficiently identify potential areas of improvement, streamline communication, and enhance overall process efficiency.

Components of SIPOC Diagrams

SIPOC diagrams are structured representations that capture the essence of a process from its beginning to its end. Let's delve deeper into the individual components that make up a SIPOC diagram:

Suppliers

Entities or individuals responsible for providing the necessary materials, information, or resources required to initiate a process.

Examples: In a manufacturing setup, suppliers could be raw material providers. In a software project, a supplier might be a third-party software vendor or a team providing specifications.

Inputs

These are the raw materials, information, or resources provided by suppliers that will transform the process.

Examples: For a bakery, inputs can be ingredients like flour, sugar, and eggs. For a digital marketing campaign, inputs might include customer demographics, budget, and marketing tools.

Process:

The set of ordered activities or operations performed on the inputs to convert them into outputs. This section maps the flow and transformation that takes place.

Examples: In a car manufacturing unit, the process could be design, assembly, painting, and quality check. In research, the process might involve data collection, analysis, peer review, and publication.

Outputs

The results, products, or services derived after the inputs have been processed.

Examples: For a restaurant, the output is the prepared dish. For a training session, outputs might be trained employees, materials distributed, and certificates awarded.

Customers

The final recipients or beneficiaries of the outputs. These can be internal or external entities.

Examples: In a retail scenario, the customer is the person buying the product. In an internal company project, other departments or teams using the project's results can be the customers.

Pros and Cons of SIPOC Diagrams

The SIPOC diagram, while highly beneficial, is not without its limitations. Below is a balanced overview of the advantages and potential drawbacks associated with this tool:

6 SIPOC Examples

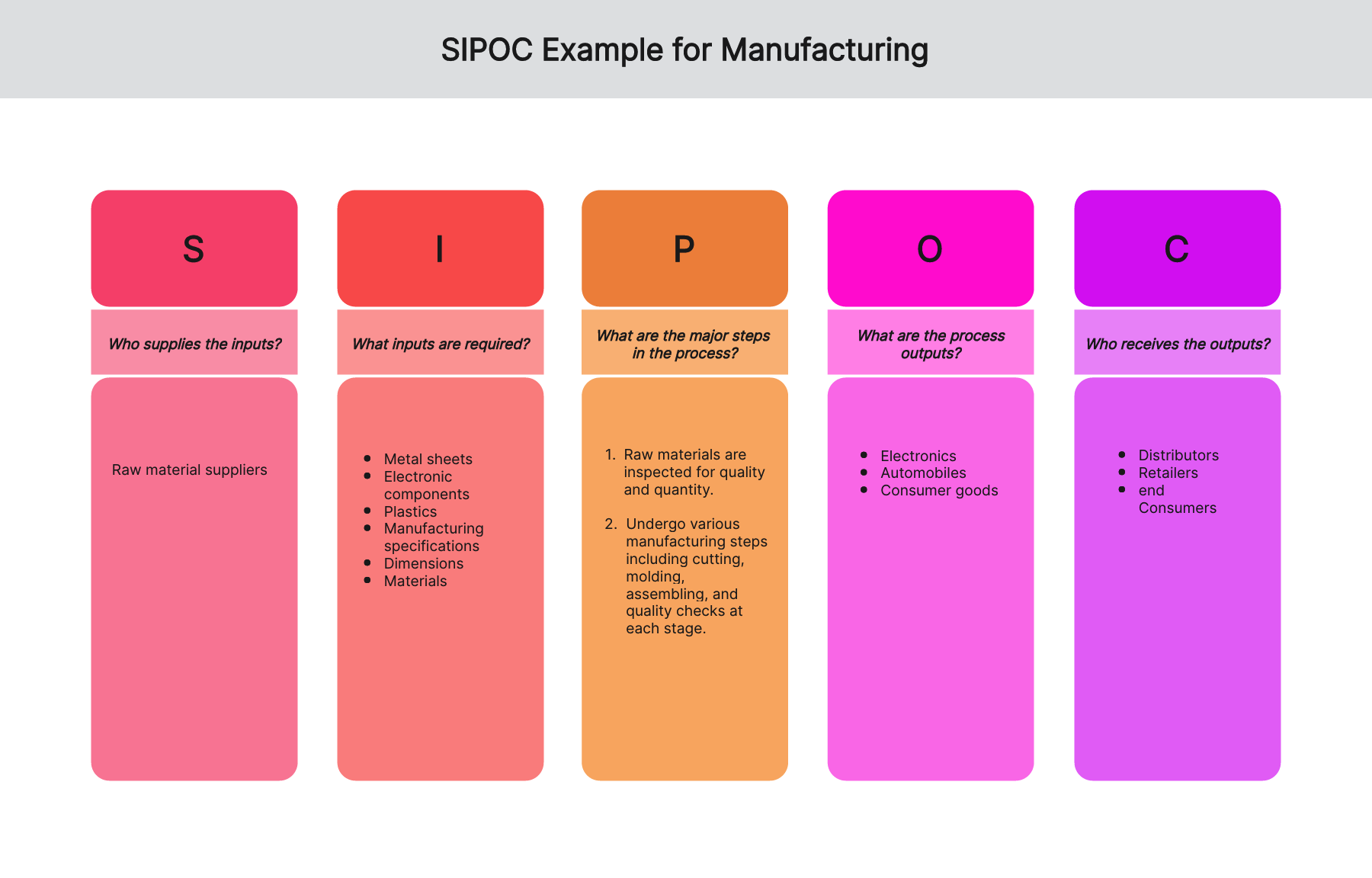

SIPOC Example for Manufacturing

- Supplier: Raw material suppliers.

- Input: Raw materials such as metal sheets, electronic components, and plastics; manufacturing specifications detailing design, dimensions, and materials.

- Process: Raw materials are inspected for quality and quantity. They undergo various manufacturing steps including cutting, molding, assembling, and quality checks at each stage.

- Output: Finished products such as electronics, automobiles, or consumer goods.

- Customer: Distributors and retailers who sell the manufactured products to end consumers.

View more SIPOC examples for manufacturing

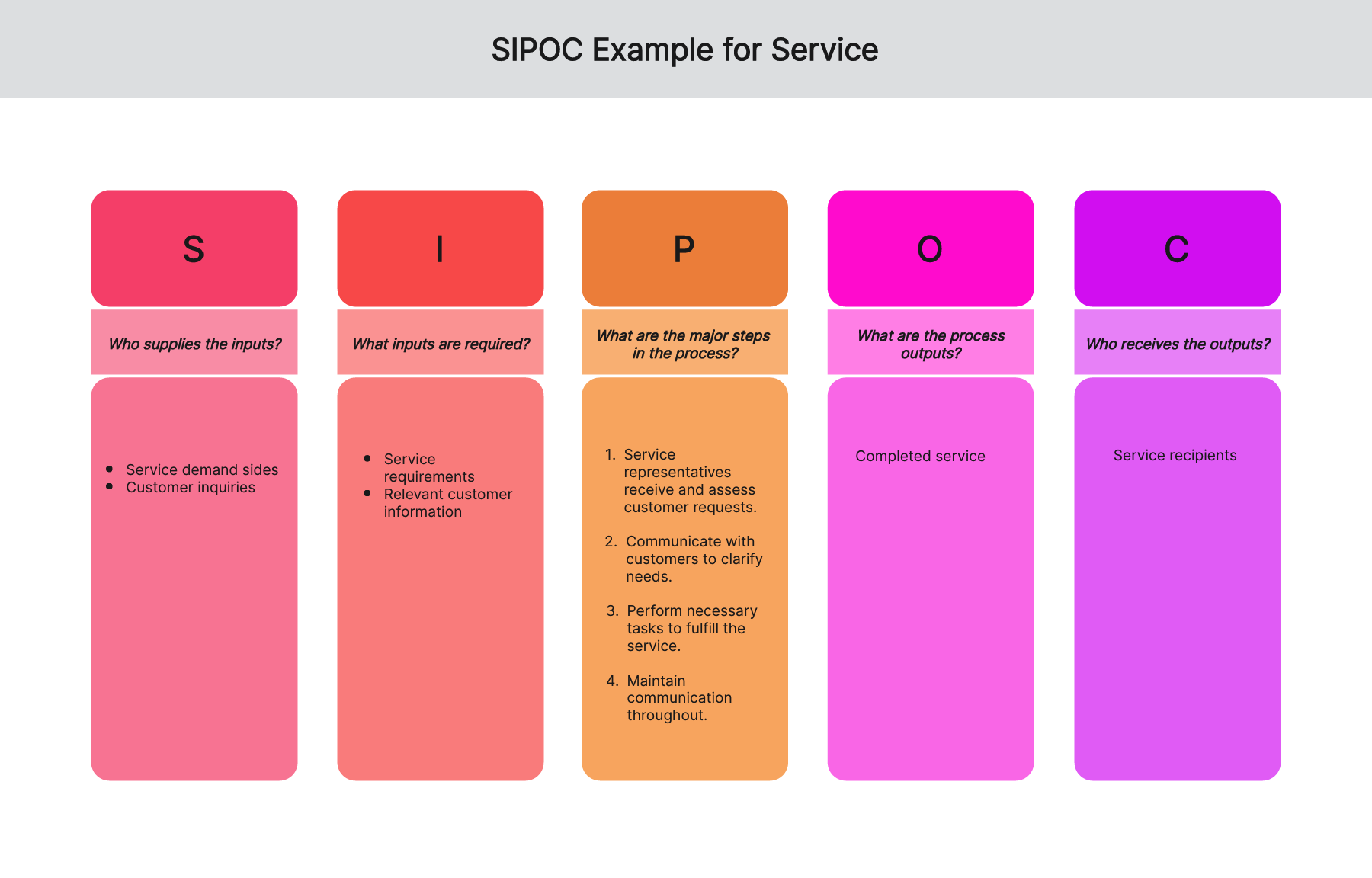

SIPOC Example for Service

- Supplier: Service demand sides, customer inquiries.

- Input: Service requirements provided by customers, relevant customer information like contact details and preferences.

- Process: Service representatives receive and assess customer requests, communicate with customers to clarify needs, perform necessary tasks to fulfill the service, and maintain communication throughout.

- Output: Completed service, which could be anything from technical support, consulting, or repair services.

- Customer: Service recipients who benefit from the provided service and the solutions offered.

View more SIPOC examples for service

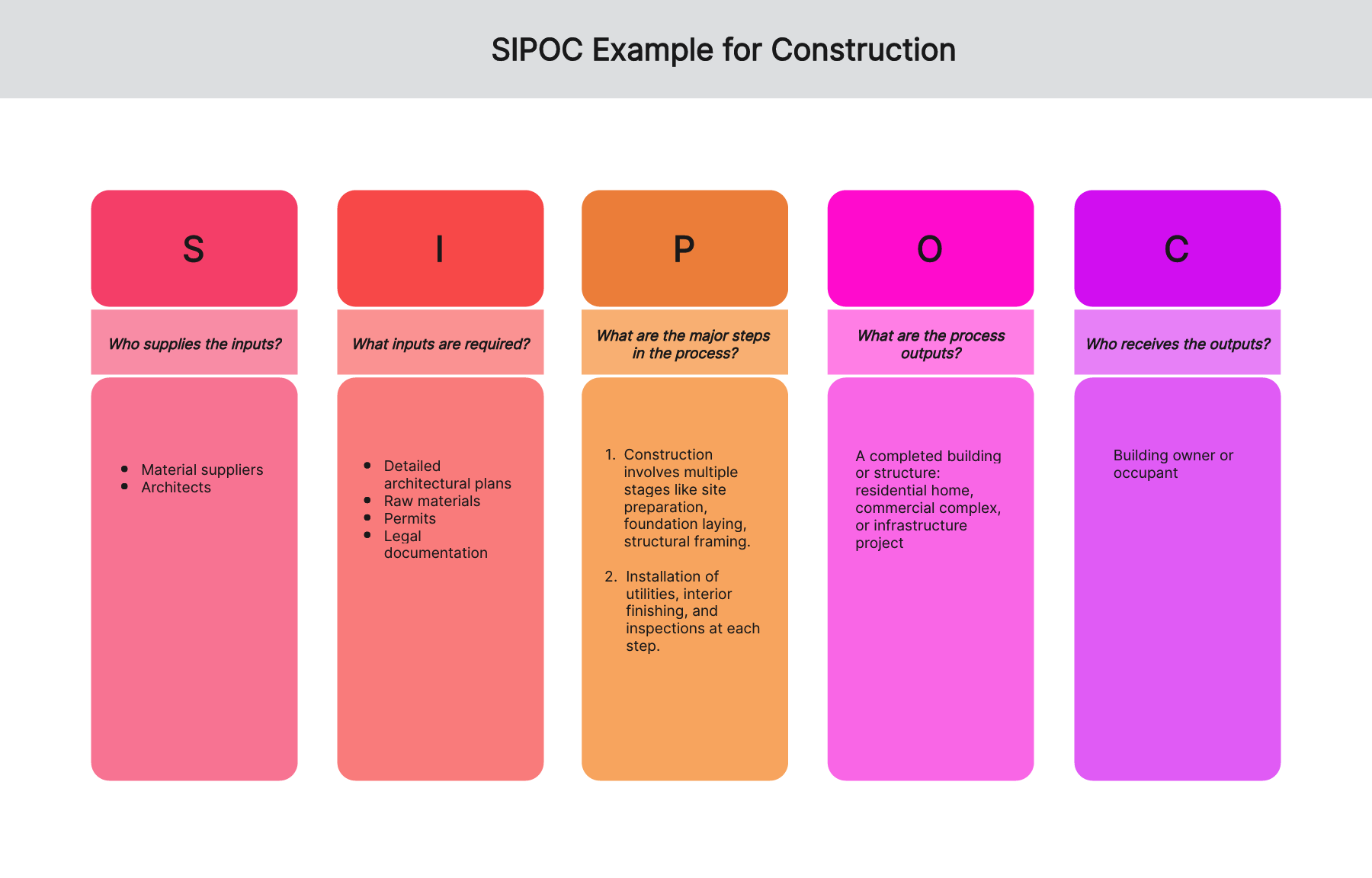

SIPOC Example for Construction

- Supplier: Material suppliers providing cement, steel, wood, etc.; architects providing building plans and specifications.

- Input: Detailed architectural plans, raw materials, permits, and legal documentation.

- Process: Construction involves multiple stages like site preparation, foundation laying, structural framing, installation of utilities, interior finishing, and inspections at each step.

- Output: A completed building or structure, whether it's a residential home, commercial complex, or infrastructure project.

- Customer: Building owner or occupant who will use the constructed space.

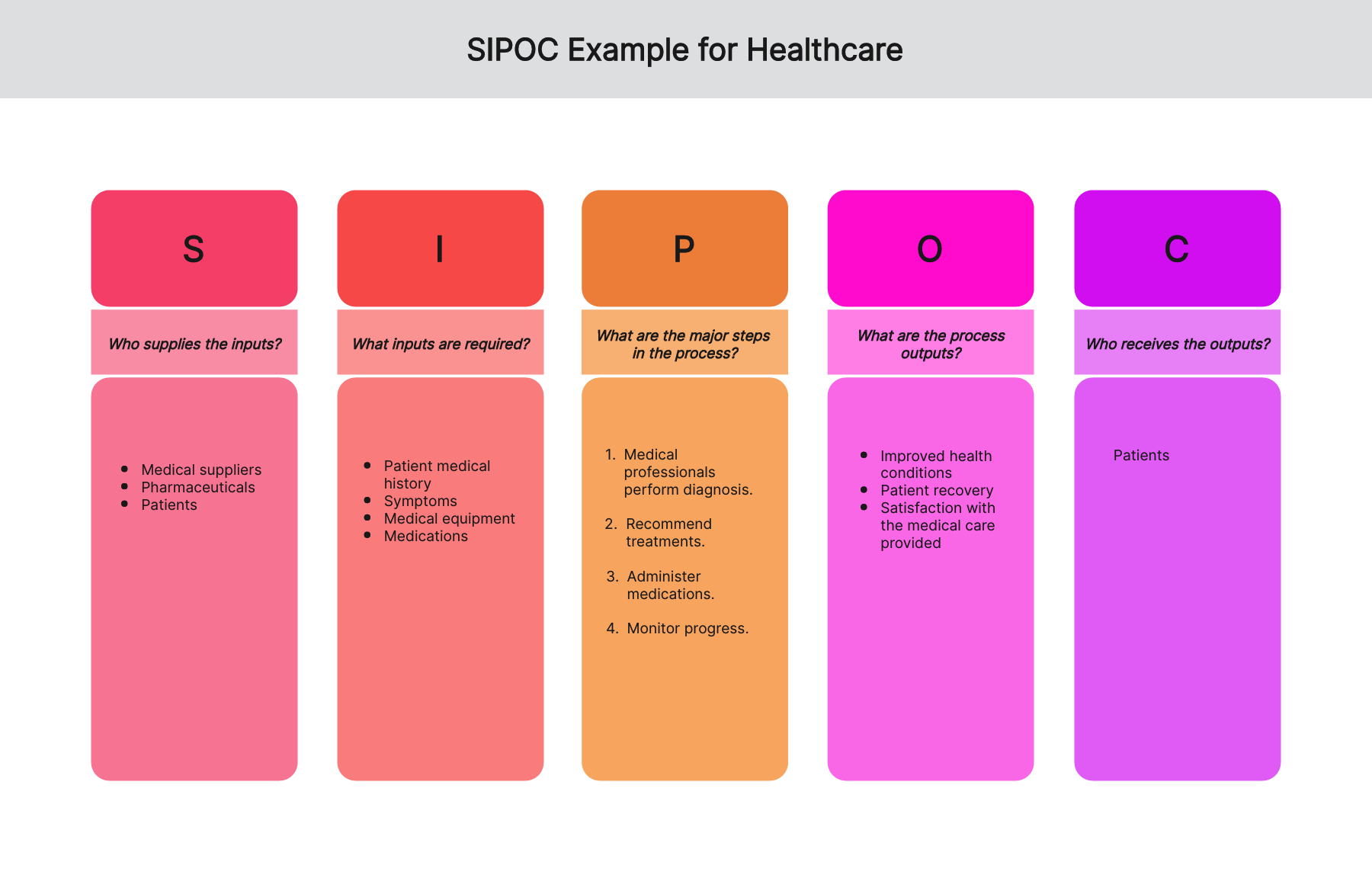

SIPOC Example for Healthcare

- Supplier: Medical suppliers providing equipment, pharmaceuticals; patients seeking medical attention.

- Input: Patient medical history, symptoms, medical equipment, and medications

- Process: Medical professionals perform diagnosis, recommend treatments, administer medications, and monitor progress. Various departments like lab tests, radiology, and pharmacy might be involved.

- Output: Improved health conditions, patient recovery, and satisfaction with the medical care provided.

- Customer: Patients who rely on healthcare services to maintain or improve their well-being.

View more SIPOC examples for healthcare

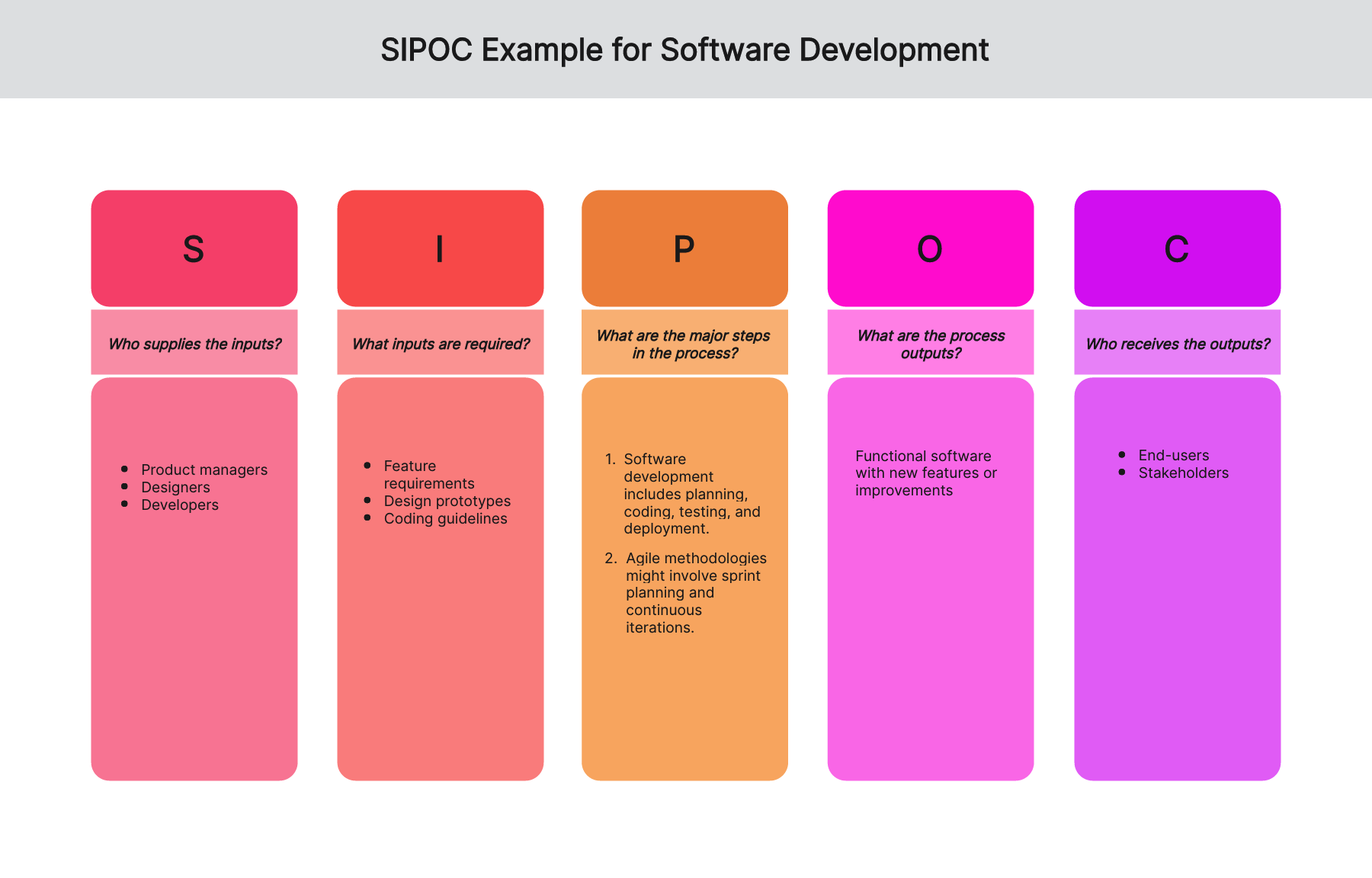

SIPOC Example for Software Development

- Supplier: Product managers defining features, designers creating mockups, developers writing code.

- Input: Feature requirements, design prototypes, coding guidelines.

- Process: Software development includes planning, coding, testing, and deployment. Agile methodologies might involve sprint planning and continuous iterations.

- Output: Functional software with new features or improvements.

- Customer: End-users who benefit from the software's functionality, and stakeholders who may be investors or business leaders.

View more SIPOC examples for software development

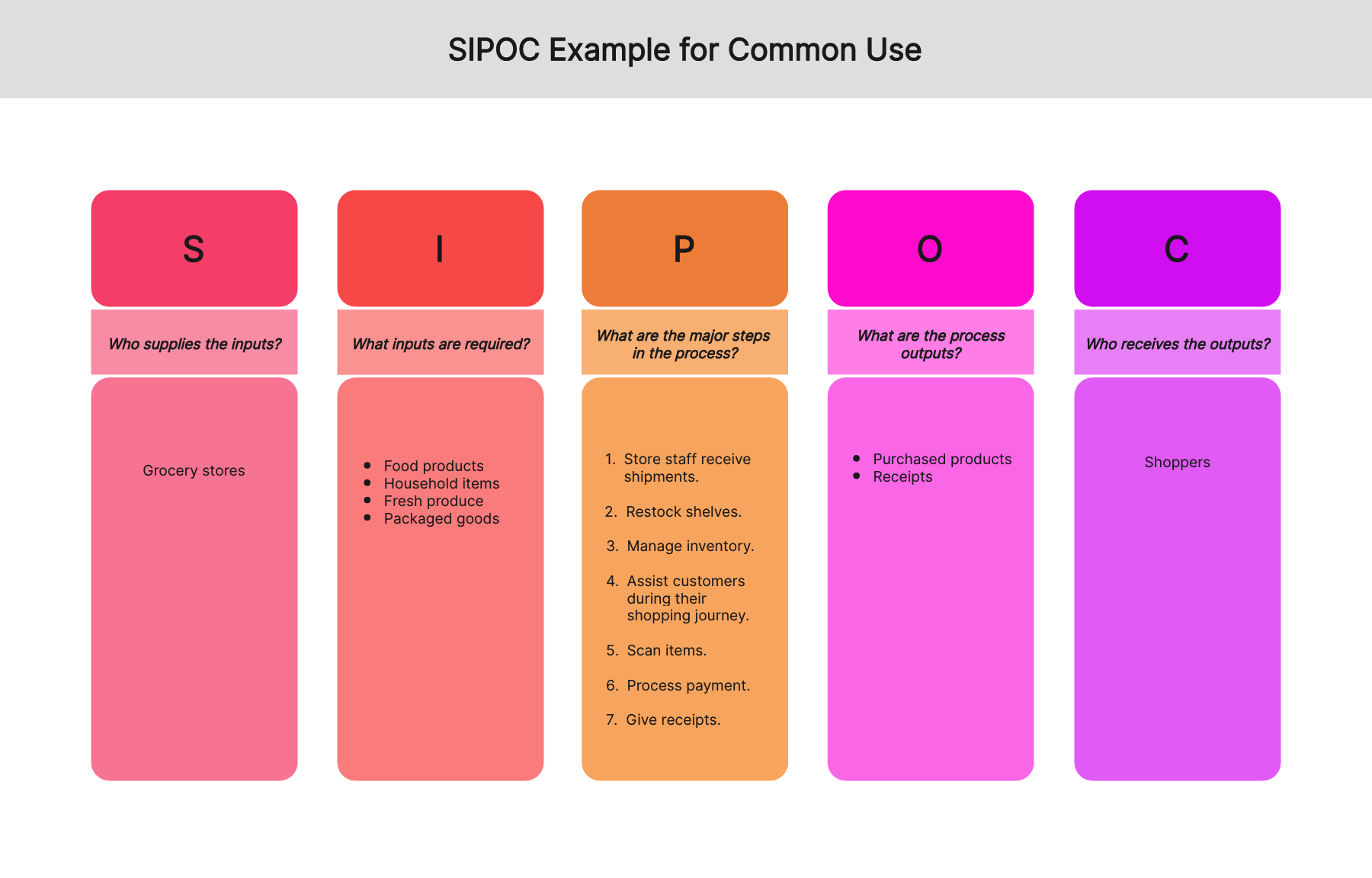

SIPOC Example for Common Use

- Supplier: Grocery stores supplying various products.

- Input: Food products, household items, fresh produce, packaged goods.

- Process: Store staff receive shipments, restock shelves, manage inventory, and assist customers during their shopping journey. At checkout, items are scanned, payment is processed, and receipts are given.

- Output: Purchased products, along with receipts as proof of purchase.

- Customer: Shoppers who visit the store to buy goods for their consumption or use.

How to Create a SIPOC Diagram

Creating a SIPOC diagram can help organizations visualize the entirety of a process, highlighting potential areas for improvement and ensuring stakeholders have a clear understanding of process boundaries. Here is how to do it step by step.

Common Tips

- Begin with the Process: While 'Suppliers' is the first element in SIPOC, starting with 'Process' can help frame the rest of the diagram. Outline the 4-5 major steps or stages.

- Engage Relevant Stakeholders: Ensure you involve individuals familiar with various stages of the process. Their insights can be invaluable.

- Use Sticky Notes in Initial Stages: Before digitalizing your SIPOC, sticky notes on a whiteboard can help in easy repositioning and modification.

- Stay High-Level: Remember, SIPOC is an overview. Avoid diving too deep into micro-processes.

- Review and Validate: Once the draft is complete, validate it with process stakeholders to ensure accuracy and completeness.

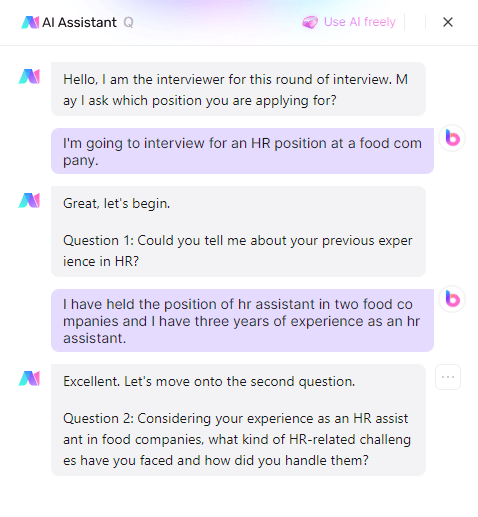

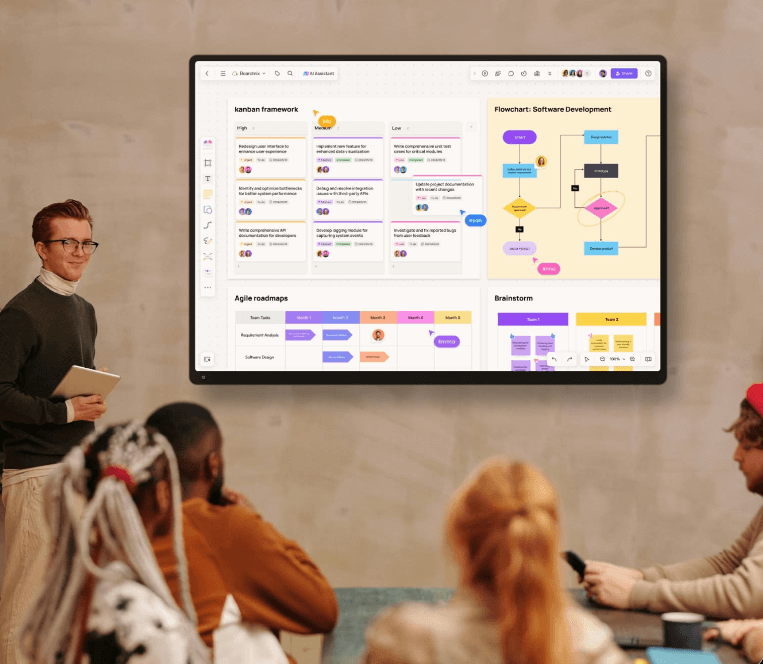

Quick Tip - Boardmix SIPOC Diagram Template

Boardmix is a user-friendly platform that provides a pre-designed SIPOC (Supplier-Input-Process-Output-Customer) diagram template. This template enables easy visualization of processes by allowing users to map out the suppliers, inputs, processes, outputs, and customers involved. Boardmix simplifies the creation of SIPOC diagrams, enhancing communication and understanding of complex processes within various industries, from manufacturing to services.

This product offers a seamless experience, providing you with ready-made templates that capture the Supplier-Input-Process-Output-Customer journey effortlessly. No need to start from scratch – simply choose the template that suits your industry and customize it to fit your process. With Boardmix, mapping out complex processes has never been more convenient. Enhance clarity, save time, and communicate effectively with our user-friendly SIPOC diagram template. Try Boardmix today and visualize your processes with ease!

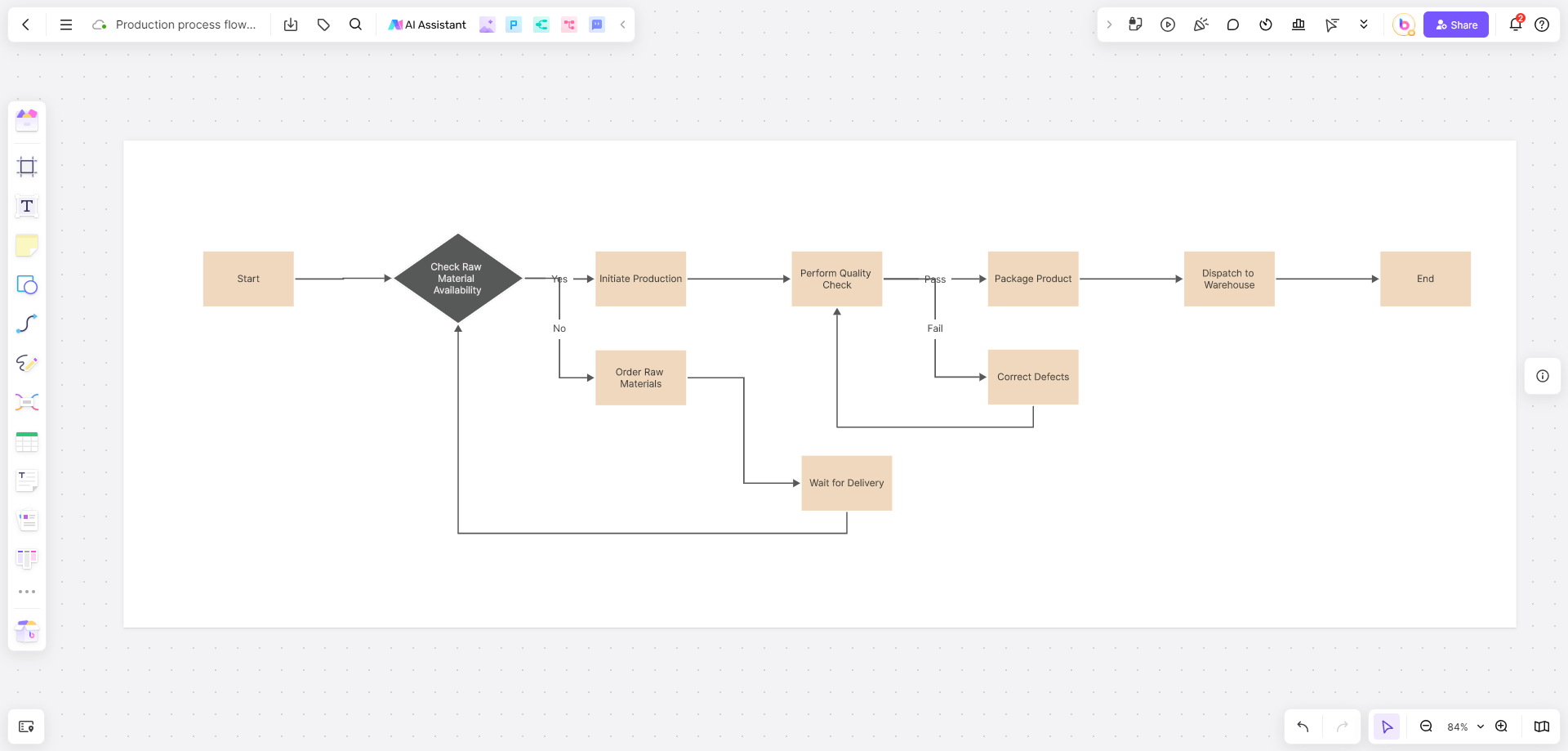

FAQ: How Is SIPOC Different from Process Flow?

SIPOC provides a high-level overview of a process, identifying the suppliers, inputs, process steps, outputs, and customers. It's a snapshot that aids in understanding the process boundaries and main components without diving deep into each activity.

Process Flow, on the other hand, is a detailed visual representation of the actual steps or activities involved in a process, often including decision points, loops, and alternative paths.

In essence, while SIPOC offers a bird's eye view, a process flow gives a step-by-step walkthrough. Both tools are valuable for process management but serve different purposes. It's not unusual for organizations to first draft a SIPOC for clarity and then delve deeper with a detailed process flow.