SIPOC, which stands for suppliers, inputs, process, outputs, and customers, is a visual tool utilized mainly in the manufacturing industry to map out processes at a high level. By breaking down processes into these five components, a SIPOC diagram offers a comprehensive view of how a manufacturing operation functions and where potential improvements can be made. So, let’s explore together and have a look over SIPOC examples for manufacturing too.

Introduction to SIPOC Diagrams

SIPOC is an acronym that stands for suppliers, inputs, processes, outputs, and customers. Originating from the realm of quality management and process improvement, SIPOC diagrams have become an indispensable tool, especially in industries such as manufacturing. Let's unravel this tool step by step.

A SIPOC diagram is essentially a visual representation that provides a high-level view of a process, starting from suppliers and ending with customers. Here's a breakdown:

Suppliers: These are entities or individuals that provide the necessary resources or materials for a process.

Inputs: These are the actual resources or materials that are required to execute the process. Inputs come from suppliers.

Process: This central component represents the core steps or activities that convert inputs into outputs. In manufacturing, for instance, it might be the assembly line where a product is made.

Outputs: The results or products that emerge from carrying out the process. It's what the process aims to produce or achieve.

Customers: The beneficiaries or recipients of the outputs. They can be internal or external entities.

How Does SIPOC Help with Manufacturing

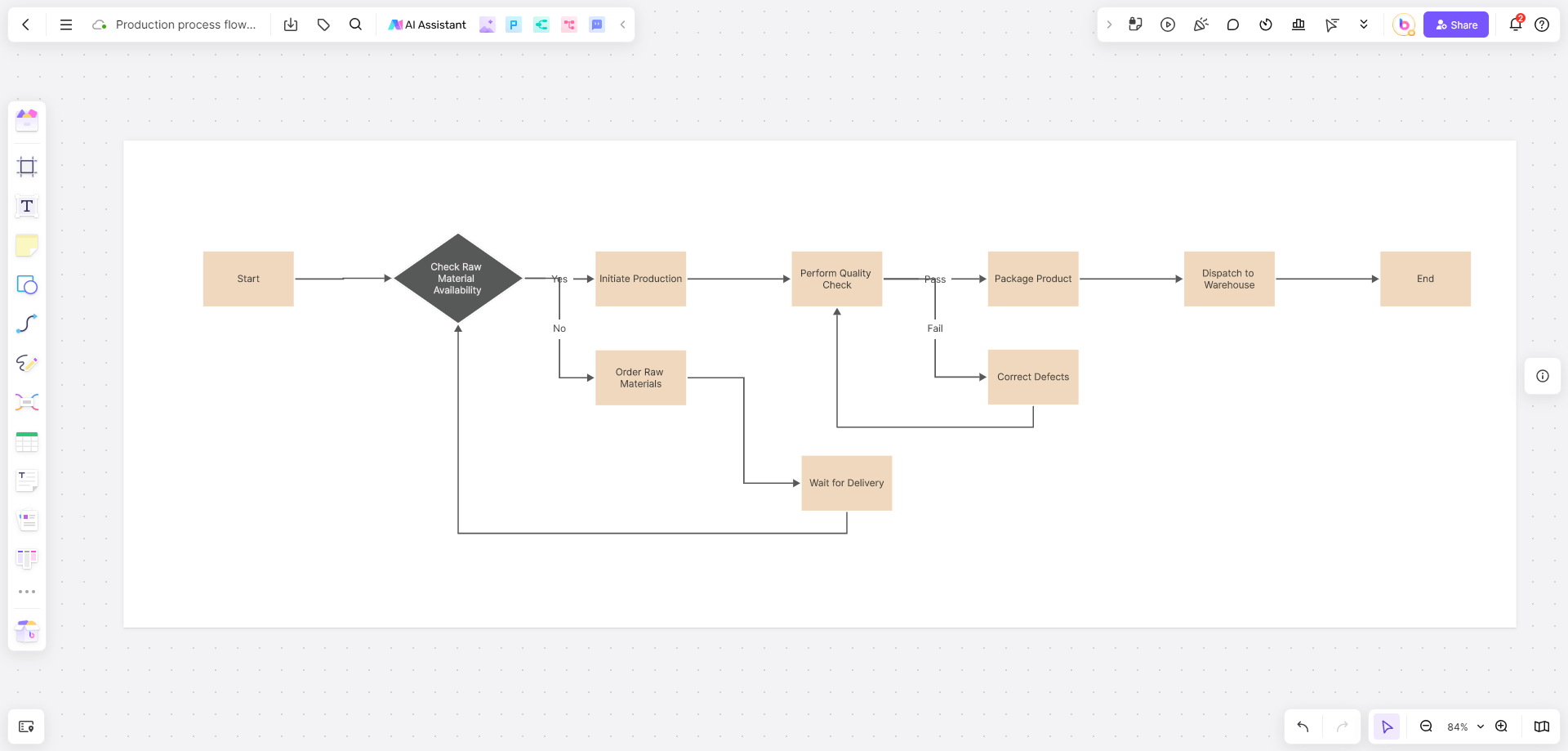

In the manufacturing sector, efficiency, accuracy, and continuous improvement are paramount. SIPOC aids by:

- Identifying Key Stakeholders: Suppliers and customers are the first and last entities in the value chain. Recognizing them helps ensure the process aligns with their needs.

- Clarifying Inputs and Outputs: By defining what's required for a process (inputs) and what the process produces (outputs), firms can better manage resources and expectations.

- Process Visualization: A SIPOC diagram provides a high-level view, helping teams understand and communicate about processes without getting lost in minute details.

- Streamlined Communication: When introducing a new process or training new team members, SIPOC serves as an invaluable communication tool. By showcasing the entire process flow, it ensures that everyone has a unified understanding, reducing miscommunication and errors.

- Facilitating Root Cause Analysis: In case of defects or process failures, SIPOC can be a starting point for root cause analysis. By understanding the suppliers, inputs, process, outputs, and customers, teams can trace back to pinpoint where things went wrong.

5 SIPOC Examples for Manufacturing

Some SIPOC diagram manufacturing examples are as follows:

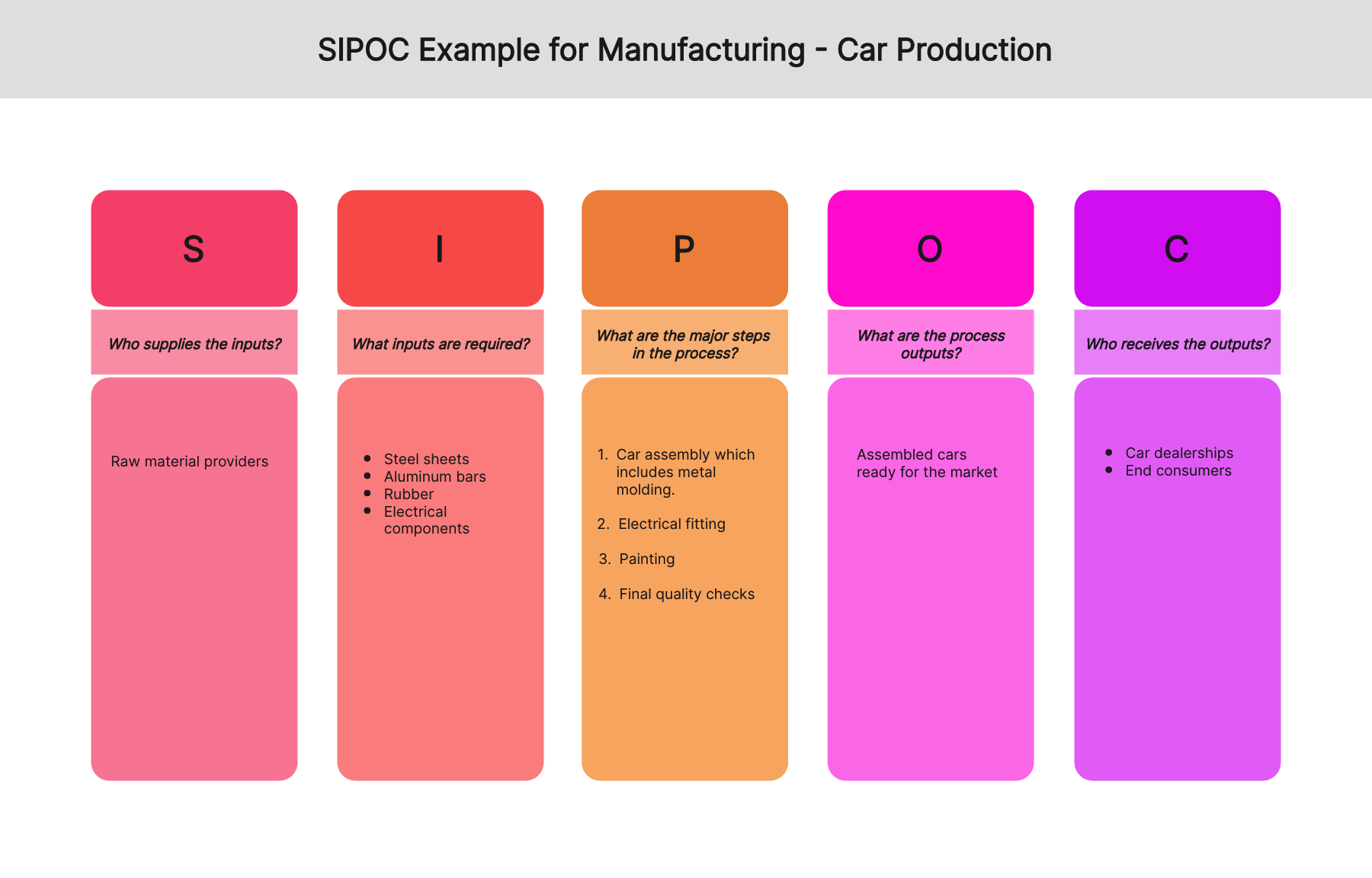

SIPOC Example for Manufacturing - Car Production

- Supplier: Raw material providers.

- Input: Steel sheets, Aluminum bars, Rubber, Electrical components.

- Process: Car assembly which includes metal molding, electrical fitting, painting, and final quality checks.

- Output: Assembled cars ready for the market.

- Customer: Car dealerships and end consumers.

Description: In this example, raw materials are sourced from various suppliers, which include steel, aluminum, rubber, and various electrical components. These inputs undergo a multi-step manufacturing process to produce the final car. Once assembled, these cars are delivered to dealerships and end consumers.

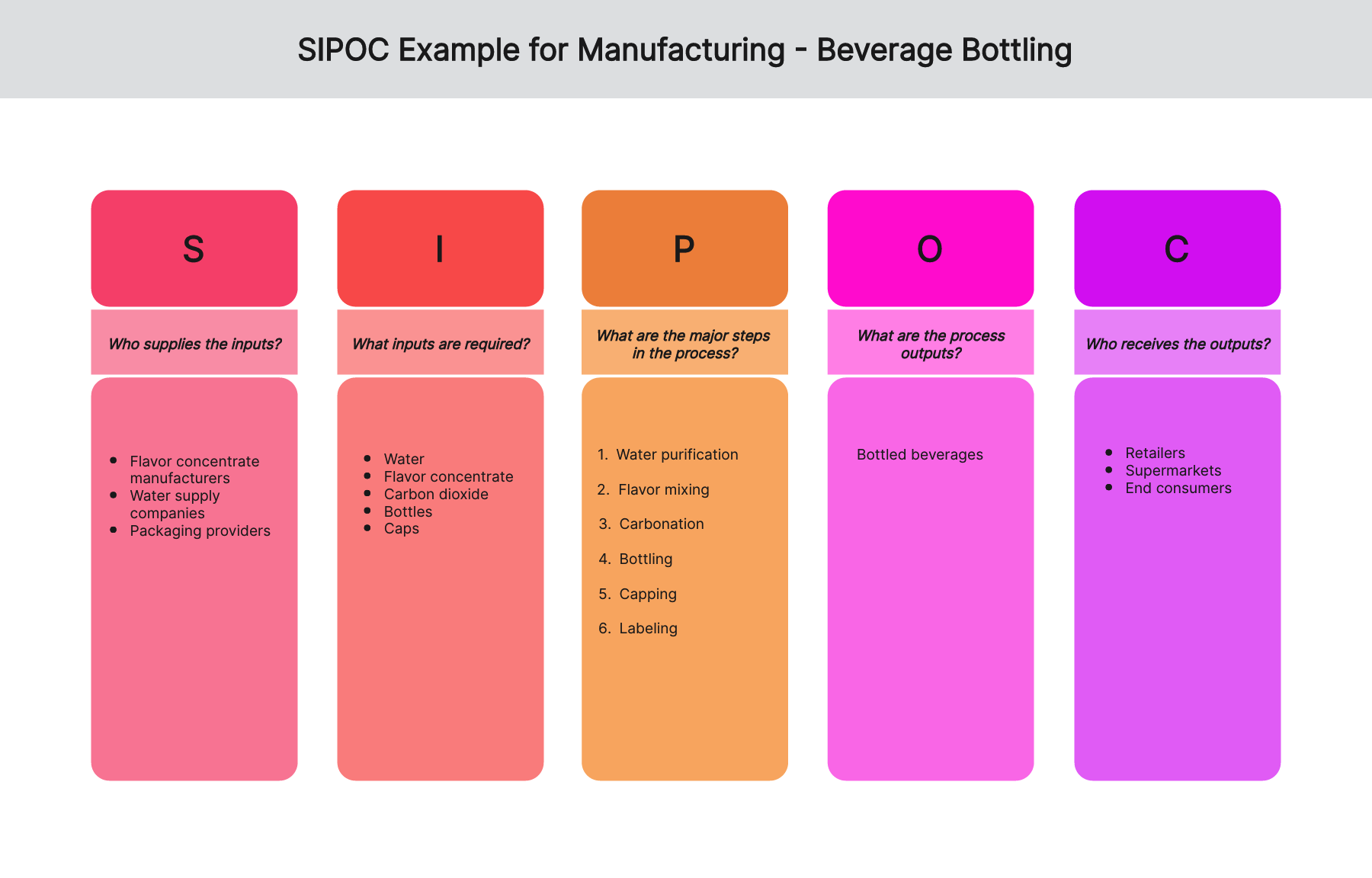

SIPOC Example for Manufacturing - Beverage Bottling

- Supplier: Flavor concentrate manufacturers, water supply companies, and packaging providers.

- Input: Water, flavor concentrate, carbon dioxide, bottles, caps.

- Process: Water purification, flavor mixing, carbonation, bottling, capping, and labeling.

- Output: Bottled beverages.

- Customer: Retailers, supermarkets, and end consumers.

Description: Water is purified and mixed with flavor concentrates. Carbon dioxide is added for effervescence. The liquid is then bottled, capped, and labeled before being shipped off to various retailers and supermarkets.

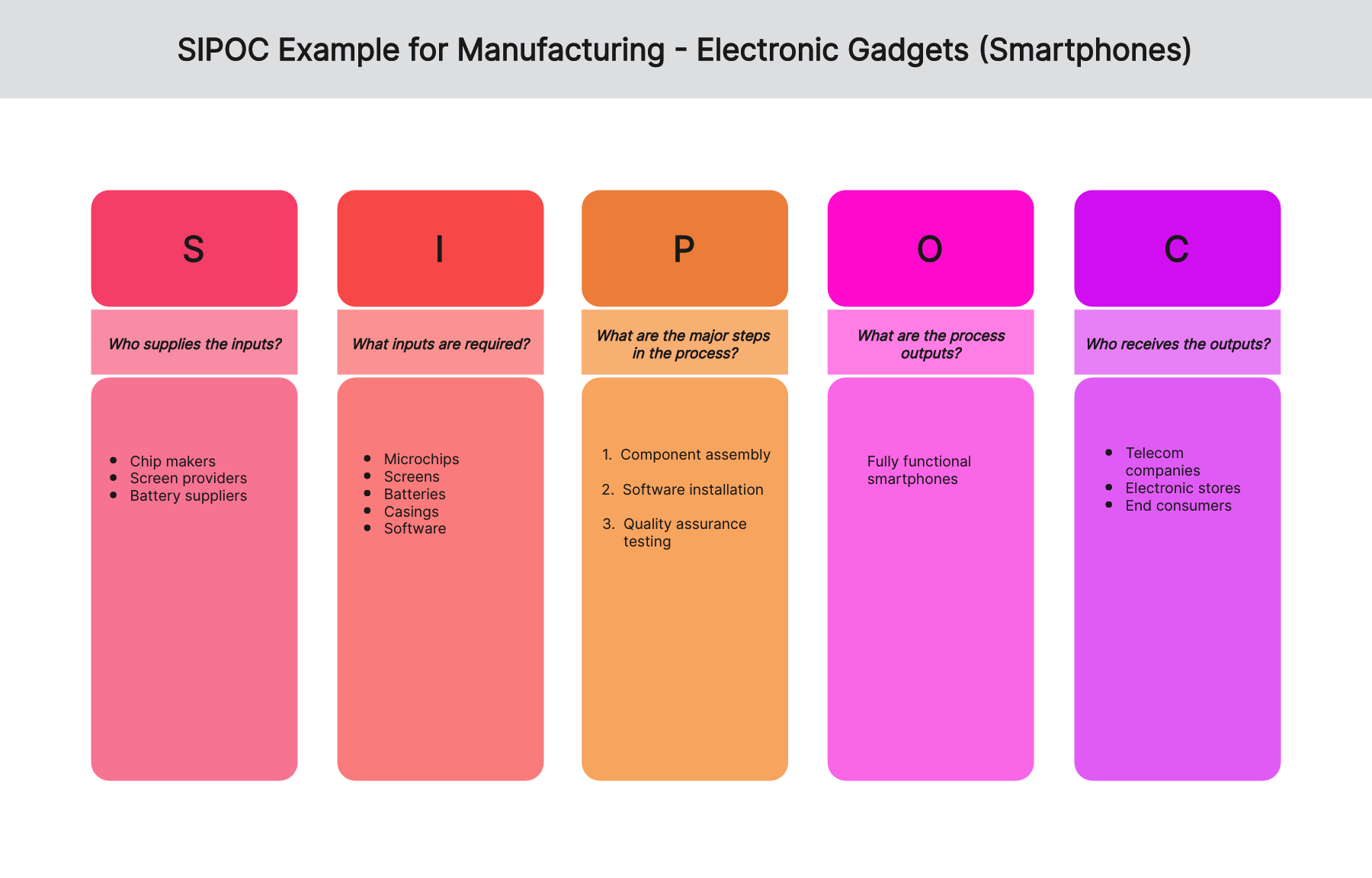

SIPOC Example for Manufacturing - Electronic Gadgets (Smartphones)

- Supplier: Component manufacturers like chip makers, screen providers, and battery suppliers.

- Input: Microchips, screens, batteries, casings, software.

- Process: Component assembly, software installation, quality assurance testing.

- Output: Fully functional smartphones.

- Customer: Telecom companies, electronic stores, and end users.

Description: Different components like chips, screens, and batteries are sourced from specialized manufacturers. These are assembled into a smartphone, with software being installed. After quality checks, the phones are distributed to telecom companies and electronic stores.

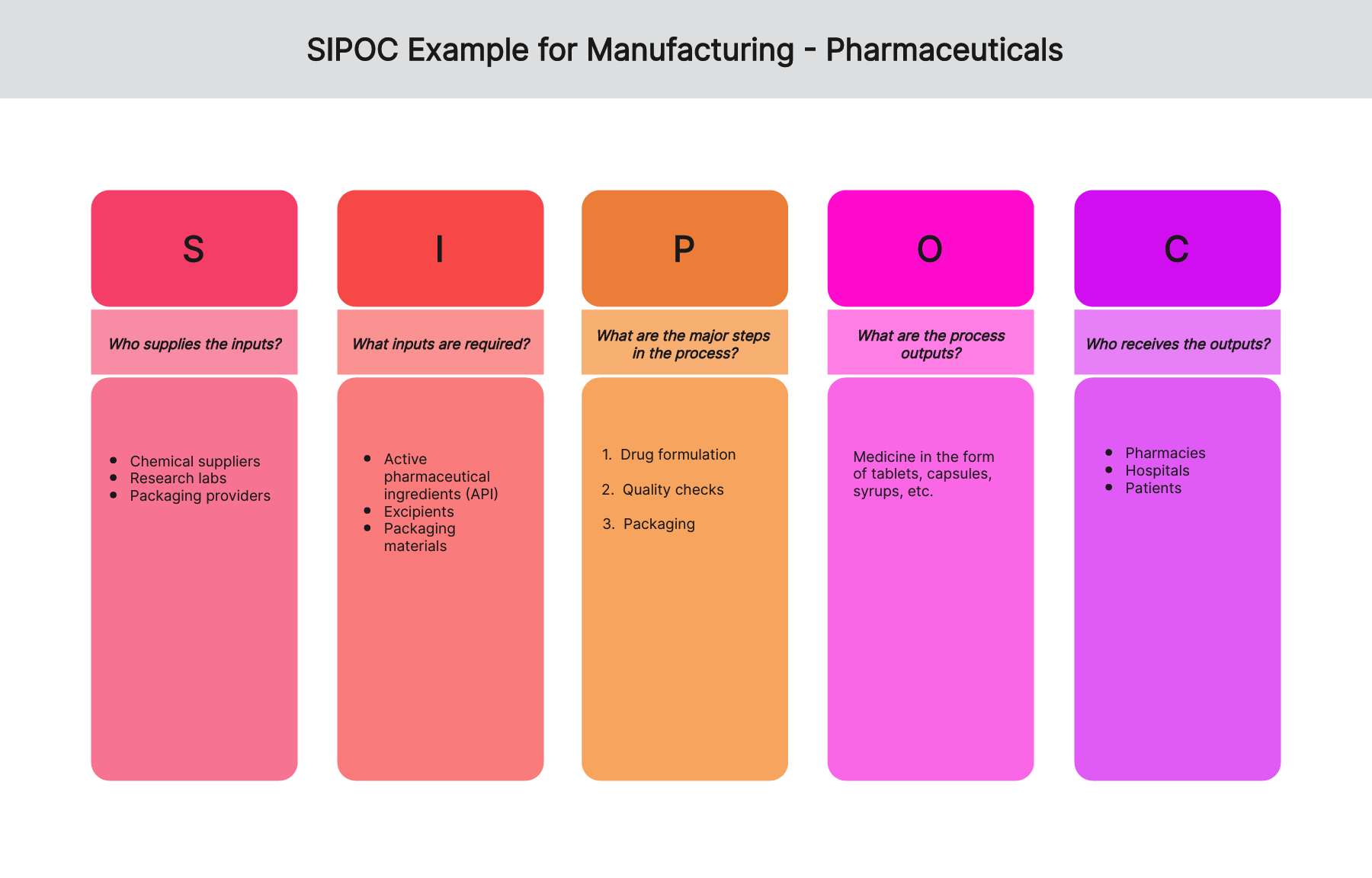

SIPOC Example for Manufacturing - Pharmaceuticals

- Supplier: Chemical suppliers, research labs, packaging providers.

- Input: Active pharmaceutical ingredients (API), excipients, packaging materials.

- Process: Drug formulation, quality checks, packaging.

- Output: Medicine in the form of tablets, capsules, syrups, etc.

- Customer: Pharmacies, hospitals, and patients.

Description: Chemicals and other ingredients are procured to formulate specific drugs. These drugs undergo strict quality checks and are then packaged into various forms like tablets or syrups. These are then distributed to pharmacies and hospitals.

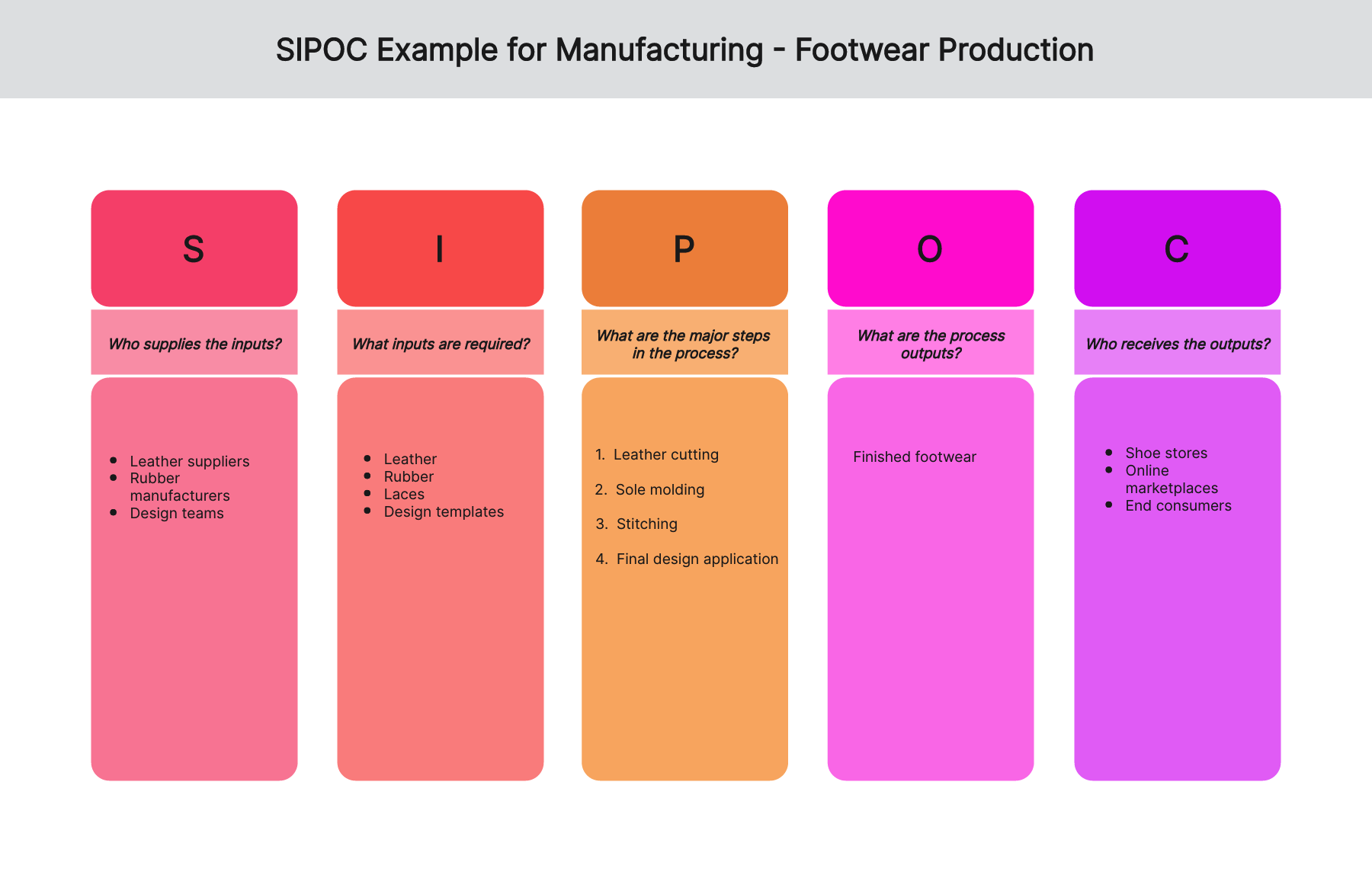

3.5 SIPOC Example for Manufacturing - Footwear Production

- Supplier: Leather suppliers, rubber manufacturers, and design teams.

- Input: Leather, rubber, laces, design templates.

- Process: Leather cutting, sole molding, stitching, final design application.

- Output: Finished footwear.

- Customer: Shoe stores, online marketplaces, and end consumers.

Description: Materials like leather and rubber are used to manufacture the shoe. The leather undergoes cutting based on design templates. The sole is molded and everything is stitched together to produce the final footwear product, which is then sent to shoe stores and online marketplaces.

Conclusion

In the vast and intricate world of manufacturing, clarity is crucial. SIPOC diagrams serve as the roadmap, ensuring all stakeholders are aligned, processes are understood, and inefficiencies are identified. As you explore the various facets of SIPOC examples for the manufacturing process, remember that tools like the user-friendly Boardmix can be indispensable allies in driving productivity and excellence. Dive in, explore, and leverage these diagrams to their fullest potential now!