Value chain analysis is a strategic analytical tool that can be applied to understand the core competencies and competitive advantage of a firm. One company that epitomizes the successful utilization of this tool is Toyota, the Japanese automotive giant renowned for its unparalleled efficiency and quality control. Let's dig into the detailed examination of the Toyota Value Chain Analysis to illustrate the critical elements contributing to Toyota's success.

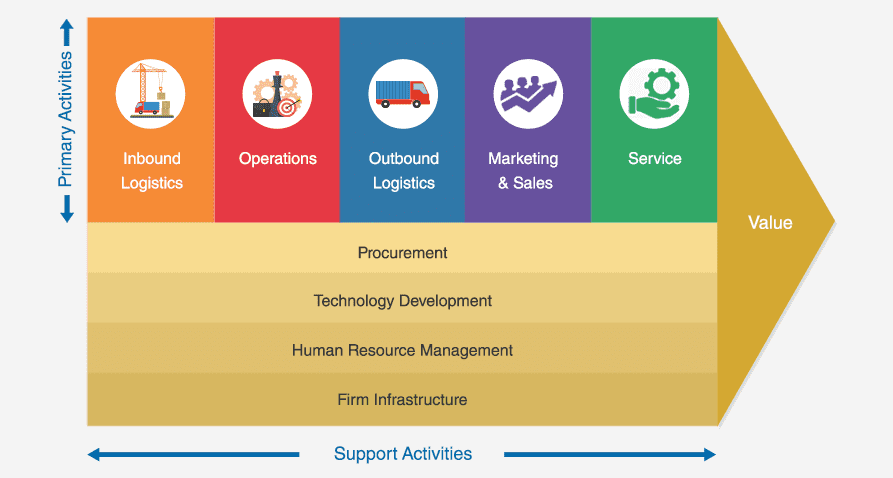

Primary Activities of Toyota Value Chain

Inbound Logistics

Inbound logistics is the first stage in the Toyota Value Chain and plays a critical role in its streamlined operations. This step encompasses the processes associated with the procurement, transportation, and storage of raw materials and components that form the backbone of Toyota's vehicles.

A distinctive element of Toyota's inbound logistics is its Just-In-Time (JIT) inventory system. With JIT, the company ensures it holds only the necessary amount of inventory needed for production, thereby eliminating waste, reducing storage costs, and improving efficiency.

Toyota collaborates with thousands of suppliers worldwide to source the components necessary for its vehicles. A testament to Toyota's supply chain efficiency is its ability to manage a multitude of suppliers and ensure they adhere to Toyota's rigorous standards. This extends not just to the quality of components but also environmental guidelines, displaying Toyota's commitment to sustainable business practices.

The success of Toyota's inbound logistics also hinges on strong supplier relationships. The company fosters mutual respect and close cooperation with its suppliers, ensuring reliable supply streams and minimizing disruptions. By doing so, it creates an environment conducive to efficiency, consistency, and mutual growth.

This collaborative approach allows Toyota to secure high-quality raw materials and components, playing a vital role in maintaining Toyota's commitment to quality and customer satisfaction.

Furthermore, by leveraging advanced technologies and IT systems, Toyota manages to keep a tight control on its procurement process and maintain real-time updates on its stock levels. This gives the company a significant advantage in terms of planning, inventory management, and cost efficiency.

Operations

Toyota's operations refer to the transformative process wherein raw materials and components are turned into finished products. This stage is perhaps the most recognized aspect of Toyota’s business model due to its innovative Toyota Production System (TPS).

The TPS, a ground-breaking operational philosophy, places a firm emphasis on continuous improvement (Kaizen) and respect for people. It promotes a relentless pursuit of efficiency, primarily through two core principles – 'Jidoka,' which means automation with a human touch, and 'Just-In-Time,' implying producing "what is needed, when it's needed, and in the amount needed".

For instance, in 2019 alone, Toyota managed to produce over 10 million vehicles, approximately one vehicle every three seconds, displaying the remarkable effectiveness of their operational processes.

A distinguishing aspect of the TPS is its focus on eliminating all forms of waste (Muda). This includes time wastage due to unnecessary motion or over-processing, excessive inventory, overproduction, defects, and underutilization of staff talent. As a result of such waste elimination, Toyota achieved an impressive productivity rate in its factories.

Moreover, Toyota's operations underscore the significance of quality control. The company follows a unique 'stop and fix' approach wherein every employee on the assembly line has the authority to halt production if they identify a potential problem. This approach ensures that issues are resolved at their source and prevents defective products from moving further down the line.

Investment in cutting-edge technologies and digitization has further streamlined Toyota's operational processes, contributing to enhanced quality control and reduced production lead time.

The phenomenal success of Toyota's operations has not only led to significant cost savings but also consistently high-quality products that have reinforced the company's reputation globally. Toyota's operations are an embodiment of its commitment to excellence and remain a benchmark for manufacturing industries worldwide.

Outbound Logistics

Once the vehicles have been produced, the next critical stage in the Toyota Value Chain is outbound logistics. This stage refers to the distribution of the finished vehicles from the manufacturing plants to dealerships and finally to the customers.

One key component of Toyota's outbound logistics strategy is its global distribution network. Toyota has approximately 170 distributors in 190 countries worldwide, and it moves over 10 million units annually, showcasing the magnitude of its logistic operations.

Furthermore, Toyota has made substantial investments in constructing an advanced logistics infrastructure. Its regional parts distribution centers are strategically located around the globe, facilitating fast and efficient delivery of vehicles.

To ensure efficiency in this operation, Toyota uses cutting-edge technologies and data analytics. Real-time tracking of consignments, advanced transport management systems, and optimized delivery routes contribute to the effectiveness of Toyota's distribution network. As a result, Toyota can reduce transportation lead time and costs while improving delivery accuracy.

Toyota's focus on maintaining strong relationships with its dealers and partners is another crucial aspect of its outbound logistics strategy. This includes regular training programs for the dealer staff to ensure they uphold the Toyota standard of service quality.

Equally important is Toyota's commitment to sustainable practices in its logistics. The company continually strives to reduce the environmental impact of its distribution activities, be it through the use of eco-friendly packaging materials or fuel-efficient transport modes.

Marketing & Sales

As one of the world's most valued automotive brands, Toyota's marketing and sales strategies have been pivotal in its global recognition. These strategies effectively engage and connect with potential customers while showcasing Toyota's unique value propositions.

Toyota's marketing strategies can be considered a mix of traditional and modern. The company utilizes various mediums such as television advertisements, print media, digital platforms, and event sponsorships to reach a diverse audience.

To illustrate, in 2019, Toyota spent approximately $1.51 billion on advertising in the United States alone, marking it as one of the top ad spenders in the auto industry. Such significant investment helps Toyota maintain a strong brand presence and customer awareness.

In recent years, digital marketing has become an essential part of Toyota's marketing efforts. The company uses online platforms, including social media channels, search engines, and email marketing, to reach out to potential customers, especially the younger demographics. For instance, in 2020, Toyota initiated the "We are Here for You" campaign across digital platforms amid the COVID-19 pandemic to communicate its commitment to customer support.

Sales strategies at Toyota are also robustly developed, with a broad network of dealerships worldwide offering an extensive range of models to cater to different customer preferences. The company also offers financing options through its financial services arm, making the purchase process more convenient for customers.

Furthermore, Toyota's sales initiatives prioritize building a long-term relationship with customers. It offers personalized services and excellent customer support, contributing to customer loyalty and repeat purchases.

Services

The final primary activity in the Toyota Value Chain is services. This stage includes all the activities that enhance the ownership experience for Toyota customers, such as after-sales services, customer support, and vehicle servicing.

Toyota is renowned for its exceptional customer service. The company believes that sales don't end when a customer buys a vehicle but extend to the entire lifecycle of that vehicle. Consequently, Toyota has set up an extensive network of service centers worldwide staffed by trained professionals dedicated to maintaining and repairing Toyota vehicles.

Toyota's services also extend to offering extended warranties, insurance services, and financing options through Toyota Financial Services, providing comprehensive support to customers.

One notable feature of Toyota's services is its focus on technology. With the rise of digitalization, Toyota has integrated technology into its service offerings. This includes online booking for vehicle servicing, real-time updates on repair status, and access to a 24/7 helpline for any assistance needed.

Additionally, the company frequently organizes training sessions for its service staff, ensuring they stay updated with the latest technological advancements in vehicles and can offer top-notch service quality.

Toyota's commitment to service excellence is also demonstrated in its customer-centric approach. It regularly seeks customer feedback and acts on it to improve its service offerings continuously.

An essential part of Toyota’s customer retention strategy involves its Toyota Owner's Club – an exclusive membership program offering various benefits, including priority bookings for vehicle servicing, special discounts, and invitations to exclusive events.

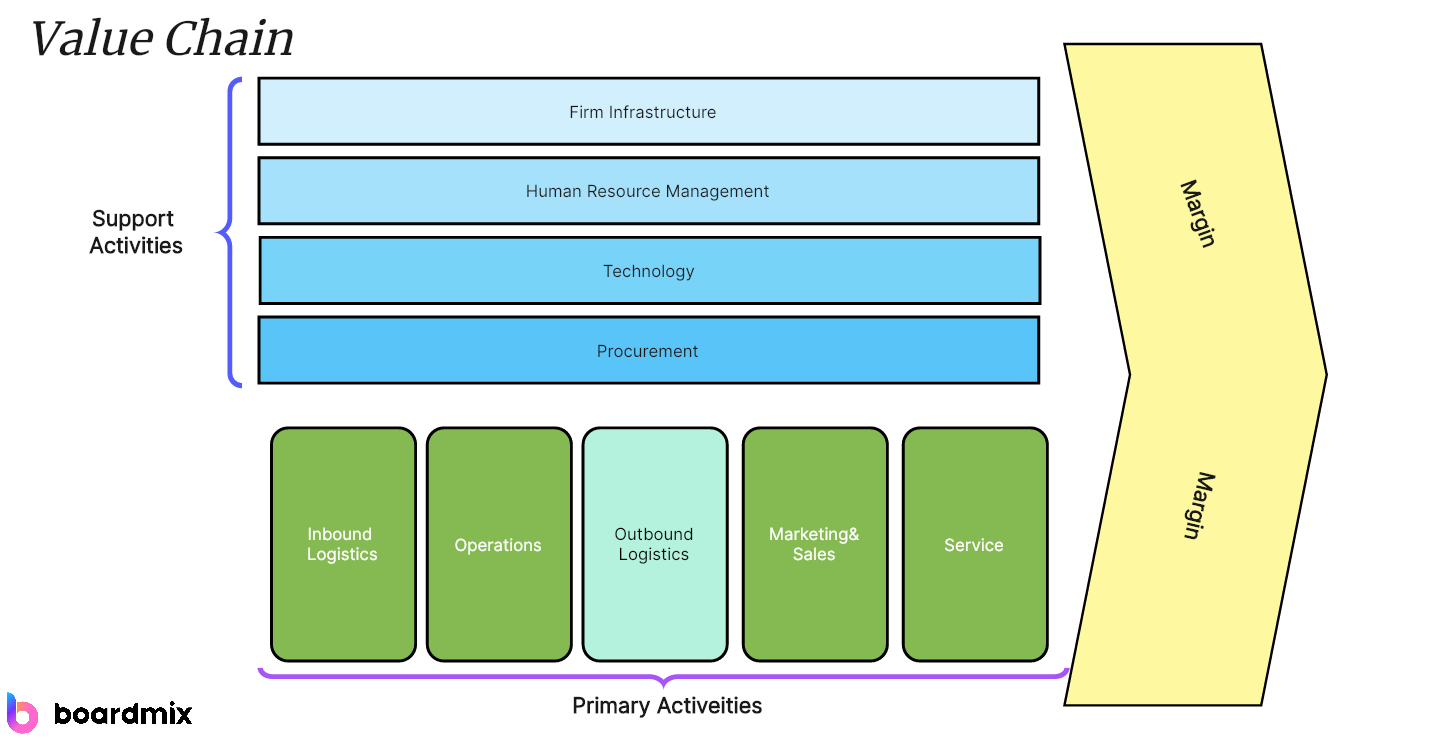

Support Activities of Toyota Value Chain

Support activities, while not directly involved in the production or delivery of the final product, are integral to the overall value chain. They strengthen the primary activities and enhance the overall efficiency and effectiveness of Toyota's operations. The support activities of Toyota's value chain comprise Infrastructure, Human Resource Management, Technology Development, and Procurement.

Infrastructure

Toyota's corporate infrastructure plays a vital role in coordinating its worldwide business operations. With a robust organizational structure that facilitates efficient decision-making and effective resource allocation, Toyota ensures its global operations run seamlessly. This includes its finance, legal, quality management, and other administrative functions that provide the foundation for its operational activities.

Human Resource Management

Human Resource Management at Toyota is about more than just hiring; it's about nurturing a culture of continuous improvement and respect for people. Through rigorous training programs and opportunities for growth and development, Toyota maintains a skilled and motivated workforce ready to uphold the company's standards of excellence.

Technology Development

In a technology-driven industry like automotive, constant innovation is a necessity. Toyota’s investment in technology development, particularly in hybrid technology and fuel cell vehicles, underlines this fact. The company’s dedication to technological advancement also extends to its production process, with innovations like the Toyota Production System (TPS) that has revolutionized manufacturing industries worldwide.

Procurement

Procurement in Toyota’s value chain isn't just about acquiring raw materials but also about building strong supplier relationships. Toyota collaborates with thousands of suppliers worldwide and ensures they adhere to the high-quality standards set by the company. By doing so, it secures the best quality components while also maintaining cost efficiency.

Toyota Value Chain Analysis Example

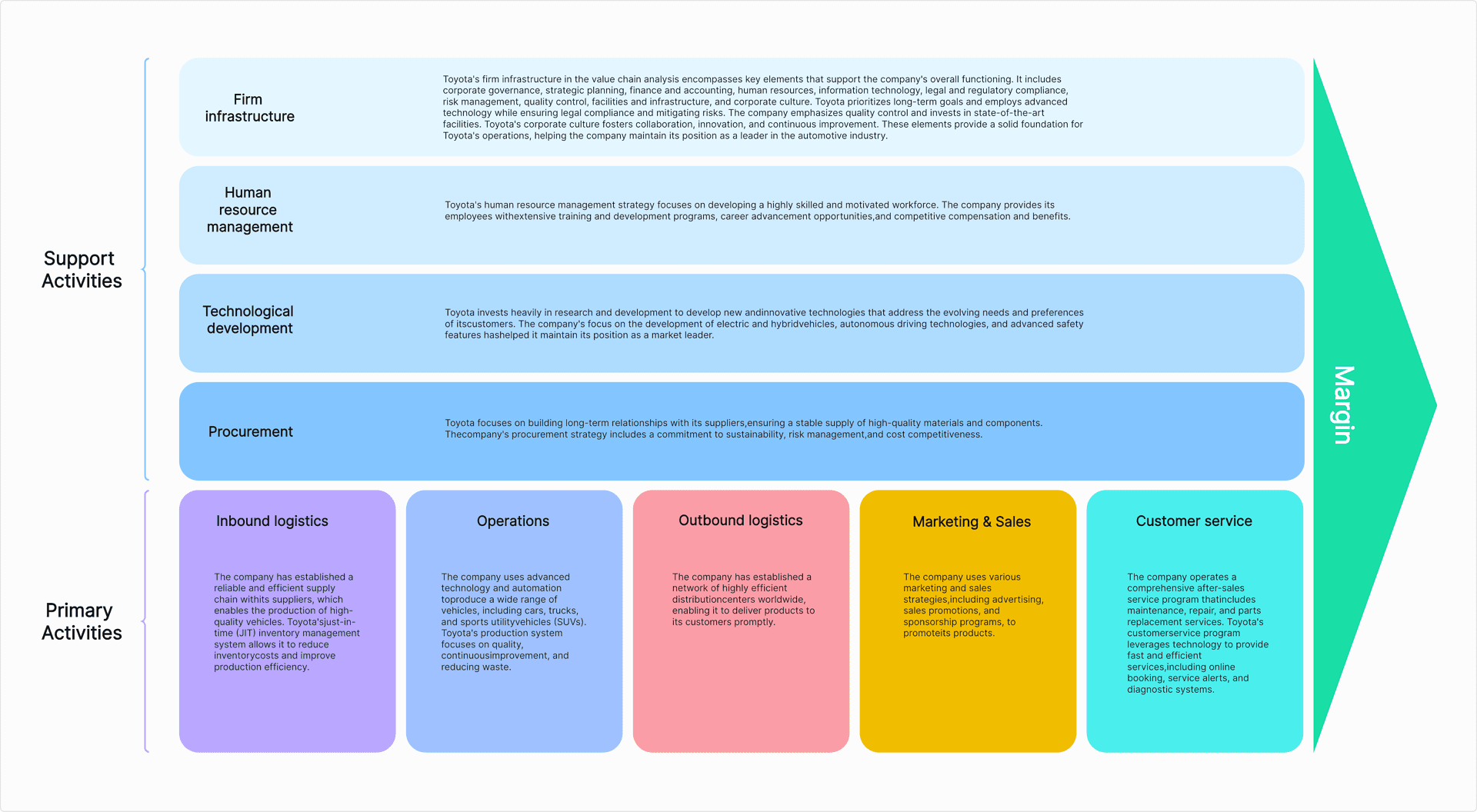

To visualize the above points more clearly, we present a simplified Toyota value chain analysis diagram. This diagram provides an easy-to-understand reference for business professionals, summarizing all the key aspects of Toyota's value chain.

Key Takeaways

The success story of Toyota, as demonstrated through its value chain analysis, offers critical insights for businesses aiming for operational excellence. Toyota's meticulously coordinated primary and support activities demonstrate a relentless pursuit of quality and efficiency – something any business can learn from.

For those looking to leverage the power of value chain analysis for their businesses, our whiteboard solution Boardmix offers an intuitive platform for mapping your value chain. Our pre-built template is designed to simplify the process, helping you quickly identify your primary and supporting activities and visualize your company's value chain just like the example above.