Embark on a journey into the realm of lean project management, a powerful methodology designed to maximize value and minimize waste. Uncover the core principles, reap the benefits, and discover essential tools for seamlessly integrating lean project management into your projects. Elevate efficiency and success with this comprehensive guide.

Part 1. What Does Lean Mean in Project Management?

Lean project management is a methodology derived from the principles of lean manufacturing, which originated in the manufacturing sector and was popularized by Toyota. The core concept of lean project management is to maximize value while minimizing waste, emphasizing efficiency, continuous improvement, and customer satisfaction. In the context of project management, "lean" refers to streamlining processes and eliminating unnecessary elements or activities that do not contribute directly to delivering value to the end customer.

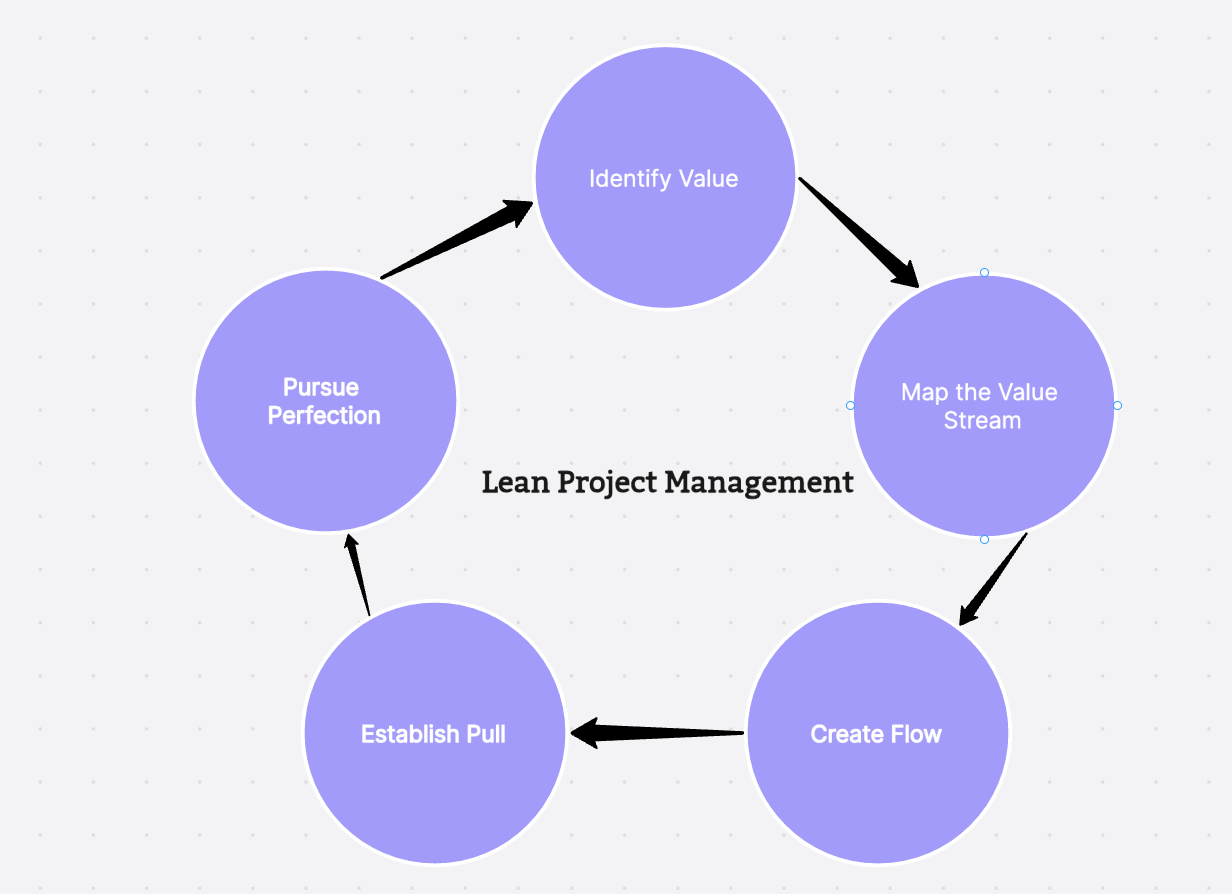

Part 2. What Are the Five Principles of Lean Project Management?

Lean project management is guided by five fundamental principles, often referred to as the "Five Principles of Lean." These principles are adapted from lean manufacturing and tailored to the context of project management. Here are the key principles:

1. Define Value from the Customer's Perspective:

- Understand what the customer values and defines as meaningful outcomes.

- Identify the key deliverables and features that contribute the most significant value to the customer.

2. Map the Value Stream:

- Analyze and map the entire process or value stream that leads to the delivery of the final product or service.

- Identify all the steps, processes, and interactions involved in creating and delivering value to the customer.

3. Create Flow:

- Streamline and optimize the workflow to reduce delays, bottlenecks, and interruptions.

- Design a smooth and continuous flow of work, ensuring that each step seamlessly leads to the next without unnecessary wait times or disruptions.

4. Establish Pull:

- Implement a pull system where work is initiated based on actual demand rather than pushing work through the system.

- Avoid overproduction and only start new work when there is a need, ensuring that resources are utilized efficiently.

5. Pursue Perfection (Continuous Improvement):

- Foster a culture of continuous improvement, known as Kaizen.

- Encourage teams to regularly review processes, identify inefficiencies, and implement changes to enhance productivity and quality.

These principles work in harmony to guide lean project management practices. By focusing on delivering value to the customer, optimizing workflows, minimizing waste, and continually improving processes, organizations can achieve greater efficiency, higher quality, and increased customer satisfaction in their project endeavors.

Part 3. Benefits of Lean Project Management

Implementing lean project management brings about several benefits that contribute to improved project outcomes and overall organizational success. Here are key advantages associated with adopting lean principles in project management:

1. Increased Efficiency:

- Lean project management eliminates waste and streamlines processes, leading to improved efficiency and reduced project timelines.

- Teams can deliver results more quickly without unnecessary delays, enabling faster time-to-market.

2. Cost Reduction:

- By minimizing waste and optimizing resource utilization, lean practices contribute to cost reduction.

- Efficient processes and better resource management lead to lower overall project costs.

3. Improved Quality:

- Focus on customer value and continuous improvement enhances the quality of project deliverables.

- Identifying and addressing issues early in the process prevents defects and ensures higher-quality outcomes.

4. Enhanced Flexibility and Adaptability:

- Lean project management encourages adaptability to changes in project requirements or customer needs.

- Agile methodologies within lean practices allow teams to respond quickly to evolving circumstances.

5. Increased Customer Satisfaction:

- Aligning project goals with customer values ensures that the end product meets or exceeds customer expectations.

- The emphasis on customer needs and preferences contributes to higher satisfaction levels.

6. Empowered and Engaged Teams:

- Lean principles often involve empowering teams to make decisions and take ownership of their work.

- This empowerment leads to increased employee engagement, motivation, and a sense of responsibility.

7. Better Risk Management:

- Continuous improvement and regular reviews of processes facilitate the identification and mitigation of risks early in the project lifecycle.

- Proactive risk management contributes to a more predictable and successful project outcome.

8. Enhanced Communication and Collaboration:

- Lean project management fosters open communication and collaboration among team members.

- Improved transparency and cooperation contribute to a more cohesive and effective project team.

9. Strategic Resource Allocation:

- Lean practices help in strategically allocating resources where they are most needed, optimizing resource usage across the project.

- This leads to a more efficient and effective allocation of time, skills, and materials.

10. Sustainable Practices:

- Lean principles emphasize sustainability by reducing waste and promoting responsible resource use.

- This aligns with environmental and social responsibility goals, contributing to a more sustainable approach to project management.

Overall, the benefits of lean project management extend beyond the immediate project scope, positively impacting the organization's overall performance and competitiveness in the long run.

Part 4. Tools for Lean Project Management

Two popular tools for implementing lean project management are:

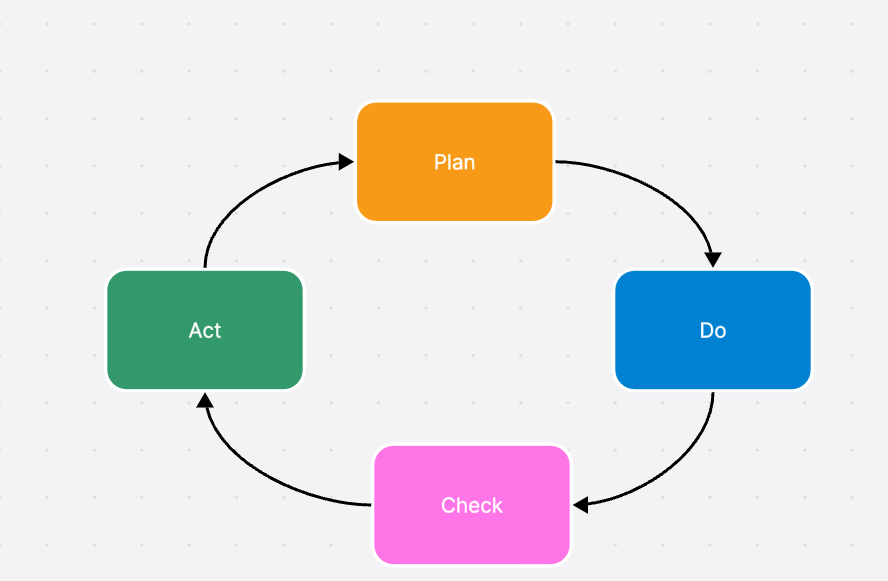

1. Deming Cycle (PDCA):

The Deming Cycle, also known as PDCA (Plan-Do-Check-Act), is a fundamental tool for continuous improvement in lean project management. Named after W. Edwards Deming, a pioneer in quality management, PDCA follows a cyclical process to drive ongoing enhancements in project processes.

PDCA involves the following stages:

- Plan: Identify opportunities for improvement, set objectives, and plan changes to address them.

- Do: Implement the planned changes on a small scale to test their effectiveness.

- Check: Evaluate and measure the results against the objectives and expectations.

- Act: If successful, implement the changes on a larger scale; if not, adjust the plan and repeat the cycle.

Application in Lean Project Management:

PDCA is a cornerstone for lean project managers seeking iterative improvements. It promotes a structured approach to problem-solving, ensuring that changes are evidence-based and align with project goals. This tool is invaluable for maintaining a focus on continuous learning and refinement throughout the project lifecycle.

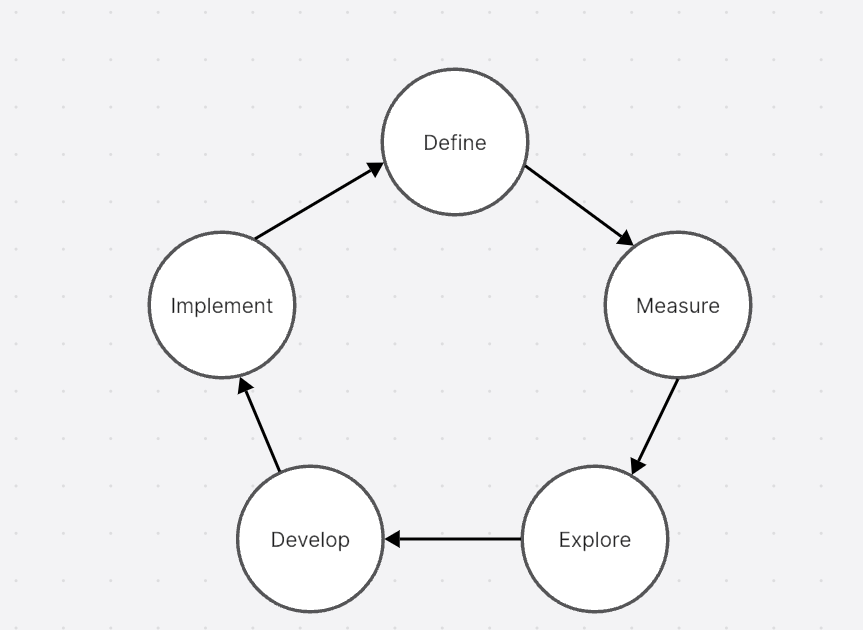

2. Lean Six Sigma Project Management (DMEDI):

Lean Six Sigma Project Management, specifically the DMEDI (Define, Measure, Explore, Develop, Implement) methodology, integrates lean principles with Six Sigma methodologies. DMEDI is a data-driven improvement cycle that aims to minimize defects and enhance overall project efficiency.

The DMEDI methodology consists of the following phases:

- Define: Clearly articulate project goals, customer requirements, and deliverables.

- Measure: Establish metrics and measure current performance to identify areas for improvement.

- Explore: Investigate potential solutions and innovations that align with lean principles.

- Develop: Implement and test the selected solution, ensuring it aligns with project objectives.

- Implement: Roll out the finalized solution, monitor its performance, and make adjustments as necessary.

Application in Lean Project Management:

DMEDI provides a systematic approach to problem-solving and project optimization by combining the strengths of lean methodologies and Six Sigma's focus on reducing variation. This tool is particularly effective in projects where data-driven decision-making and a rigorous problem-solving approach are crucial for success.

By incorporating these tools into lean project management practices, teams can ensure a robust framework for continuous improvement, data-driven decision-making, and the successful execution of projects with minimal waste and maximum value delivery.

Part 5. How to Use Boardmix for Lean Project Management

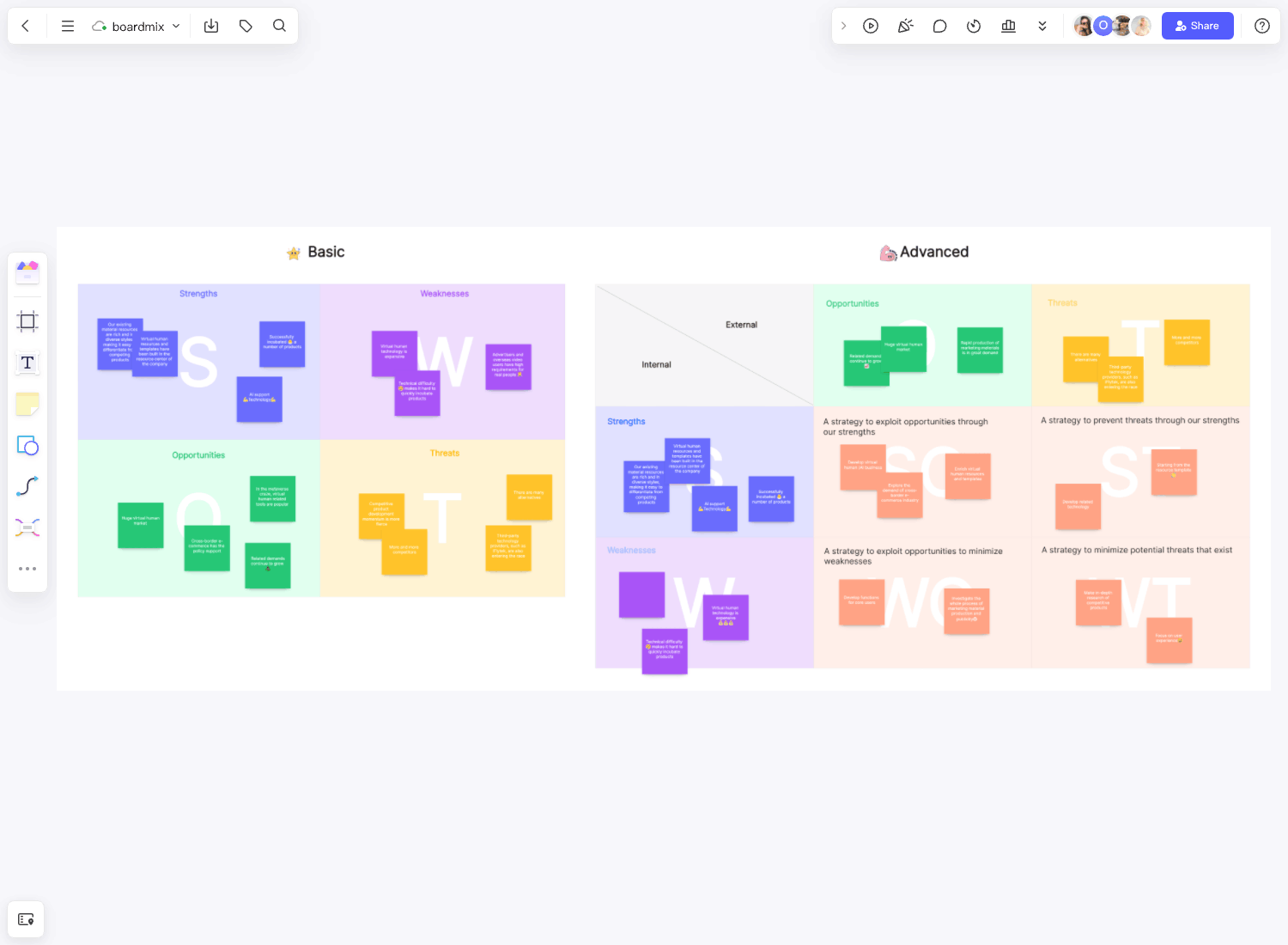

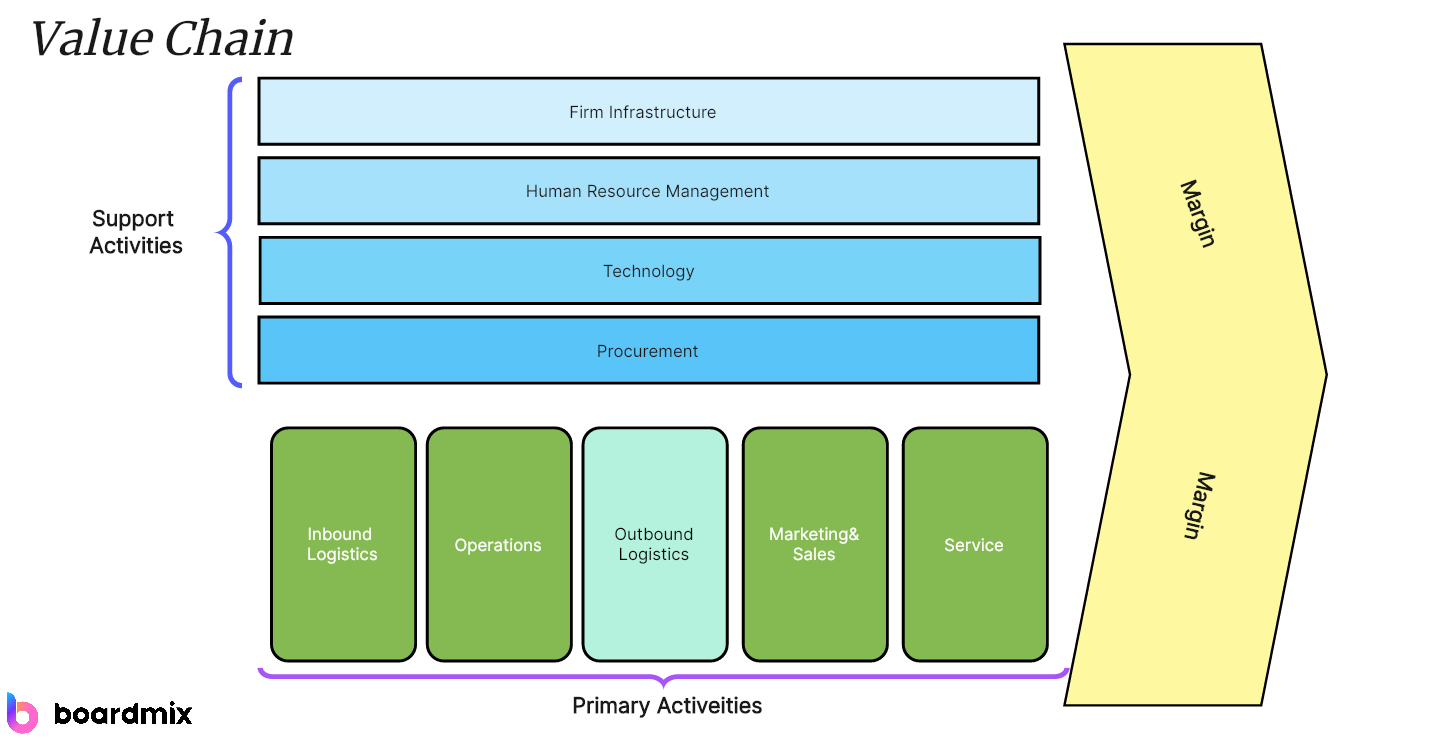

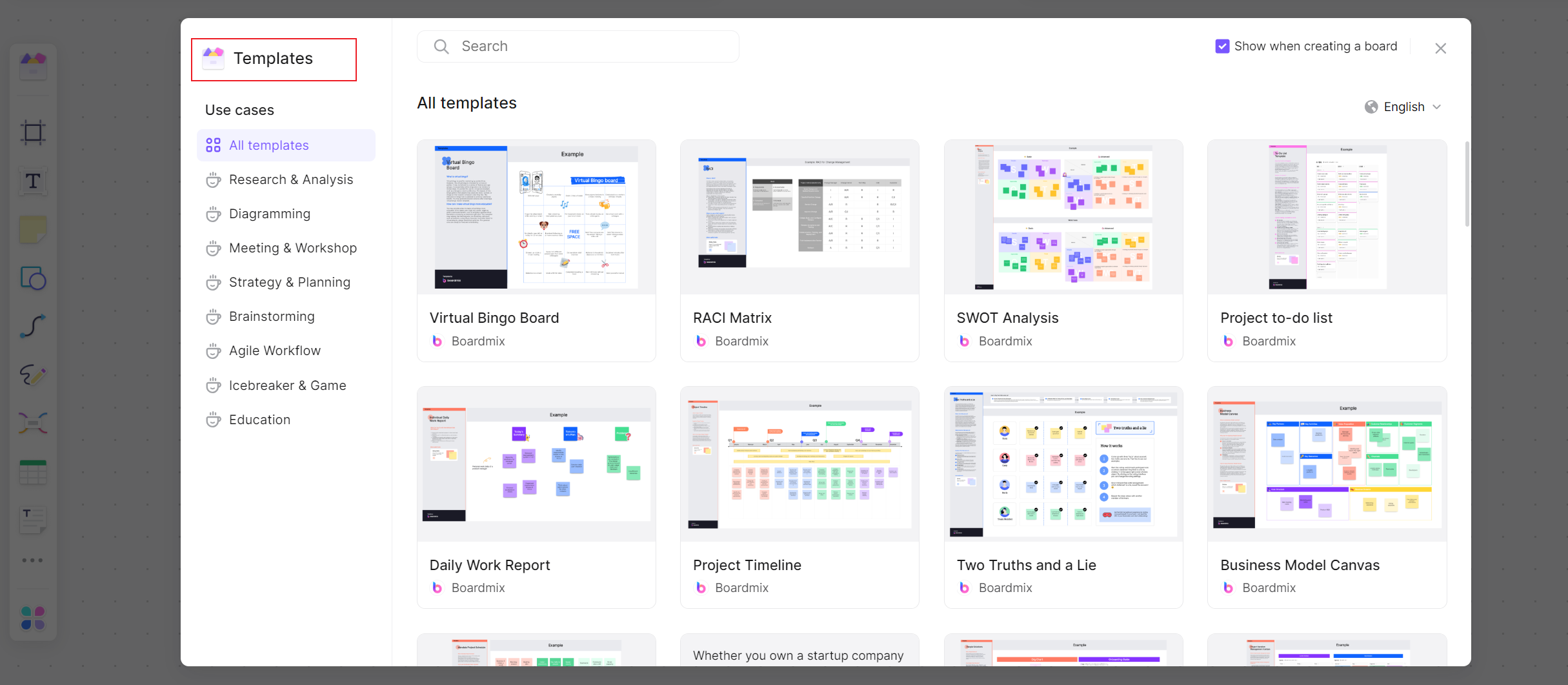

Boardmix is an innovative online whiteboard tool that perfectly aligns with the principles of lean project management. It's designed to maximize value and minimize waste in your project workflows, making it an ideal solution for teams aiming to implement lean methodologies. With Boardmix, you can visualize your value stream on a virtual canvas, identify bottlenecks, and streamline processes in real-time. Its pre-made templates facilitate efficient planning and continuous improvement - key aspects of lean management. While Boardmix currently doesn't integrate with other platforms, its comprehensive standalone features make it a powerful tool for driving efficiency and eliminating waste in your projects. Embrace the lean approach with Boardmix and experience enhanced productivity, improved quality, and increased customer satisfaction.

Key features of Boardmix:

- Visualize Ideas: Easily sketch out ideas and plans on a virtual canvas.

- Collaborate Real-Time: Work together with your team regardless of location.

- Use Templates: Utilize pre-made templates for efficient planning.

- Track Progress: Monitor tasks and timelines easily.

- Integrate Tools: Although not yet integrated with other platforms, Boardmix provides comprehensive features for efficient project management.

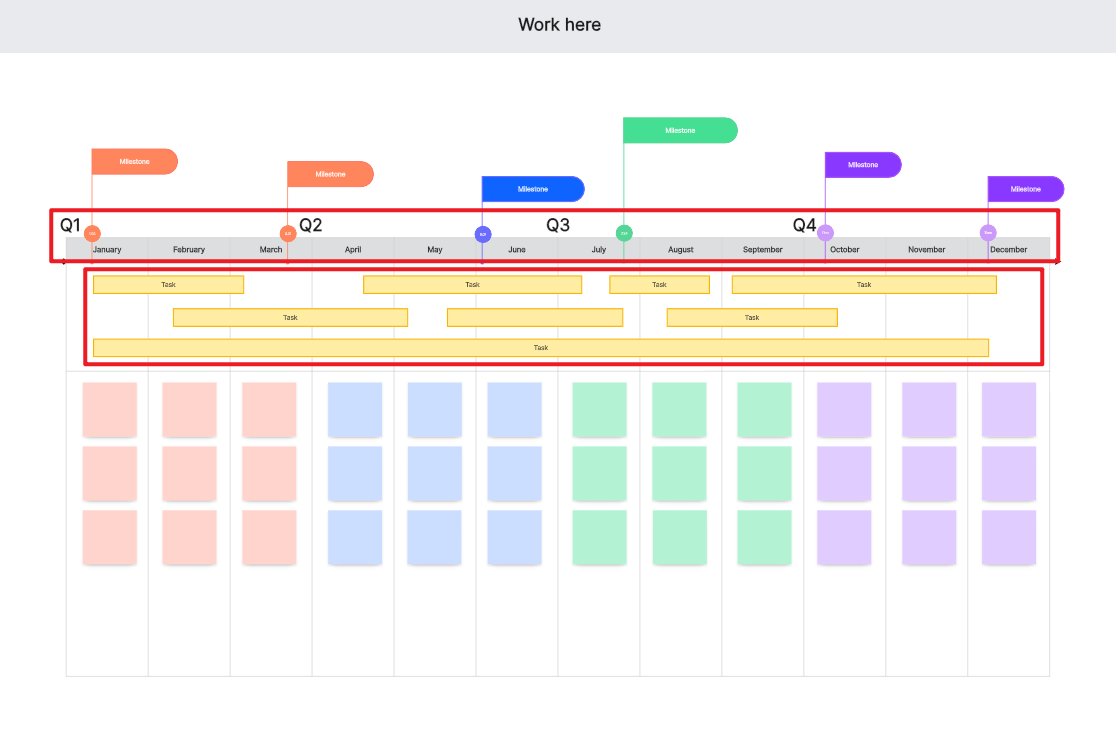

Here's a more detailed step-by-step guide on using Boardmix for lean project management:

Step 1: Sign up or log in to Boardmix.

Step 2. Define Your Goals: Start by identifying the value you aim to deliver through your project. Choose a propriate template from Boardmix to jot down your objectives and goals.

Step 3: Map Out Your Process: Visualize your entire workflow on Boardmix's virtual canvas. Identify all steps in the process, pinpoint non-value-adding activities, and plan how to eliminate them.

Step 4: Collaborate with Your Team: Invite your team members to join your Boardmix workspace. Work together in real-time, brainstorm ideas, assign tasks, and make collective decisions.

Step 5: Track Progress: Use Boardmix's tracking features to monitor task completion and timeline adherence. Produce only what is needed when it's needed - establishing pull, the fourth principle of lean.

Step 6: Pursue Perfection: Continually review and improve your processes using Boardmix.

By following these steps, you can effectively use Boardmix as a tool for implementing lean project management principles in your projects.

Conclusion

Lean project management, with its focus on delivering maximum value while minimizing waste, offers a plethora of benefits including increased efficiency, improved quality, and enhanced customer satisfaction. Boardmix's intuitive features allow for effective collaboration, streamlined planning, and real-time progress tracking. This makes implementing lean principles not just feasible but also efficient. So why wait? Start your journey towards lean project management today with Boardmix and experience a transformation in how you manage projects. Discover the power of lean and let Boardmix be your guide to achieving operational excellence.