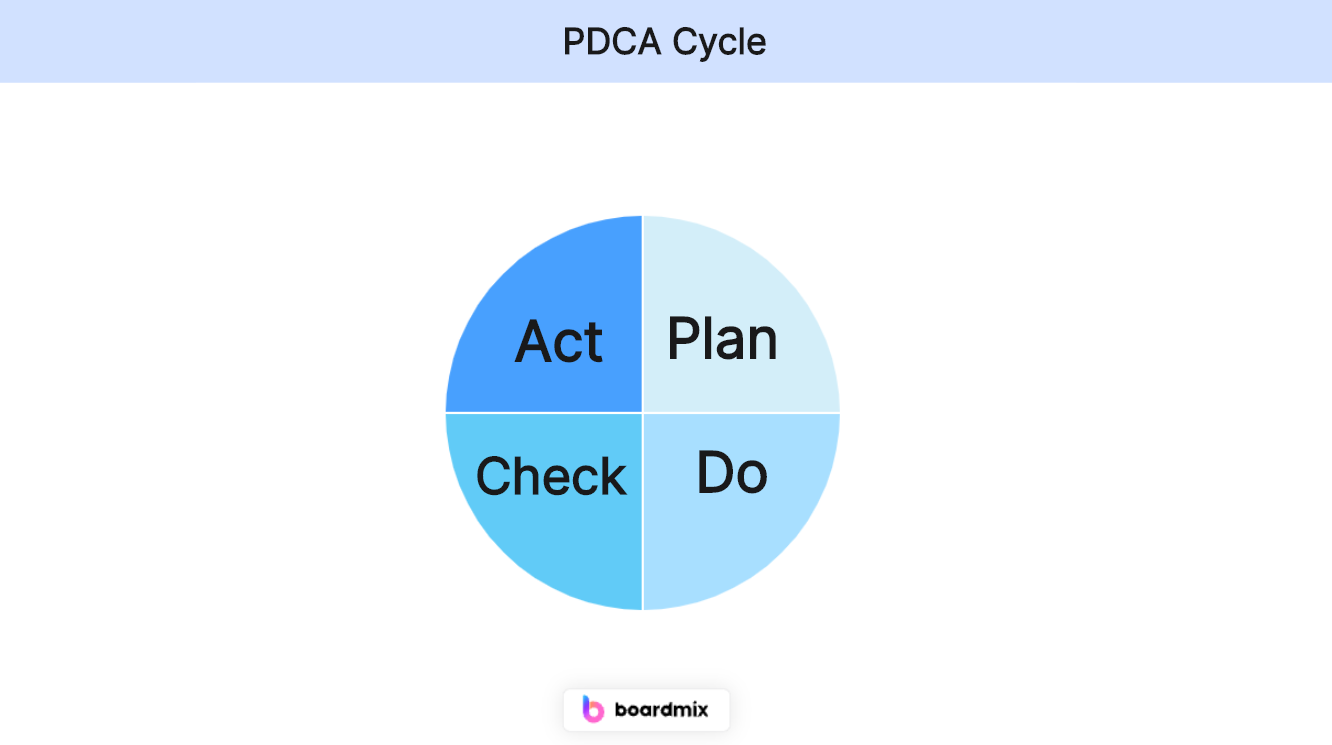

The PDCA Cycle, also known as the Deming Cycle or Plan-Do-Check-Act Cycle, is a systematic and iterative approach to problem-solving and continuous improvement. Developed by renowned statistician and management consultant W. Edwards Deming, the PDCA Cycle has become a fundamental tool for organizations striving to enhance their processes and achieve long-term success.

Part 1. What Is the Meaning of PDCA Cycle?

The PDCA cycle, also known as the Deming Cycle or Plan-Do-Check-Act cycle, is a management and continuous improvement methodology. It is a four-step iterative process that can be applied to improve and optimize processes, products, or services in various industries. The PDCA cycle was popularized by the quality management guru W. Edwards Deming.

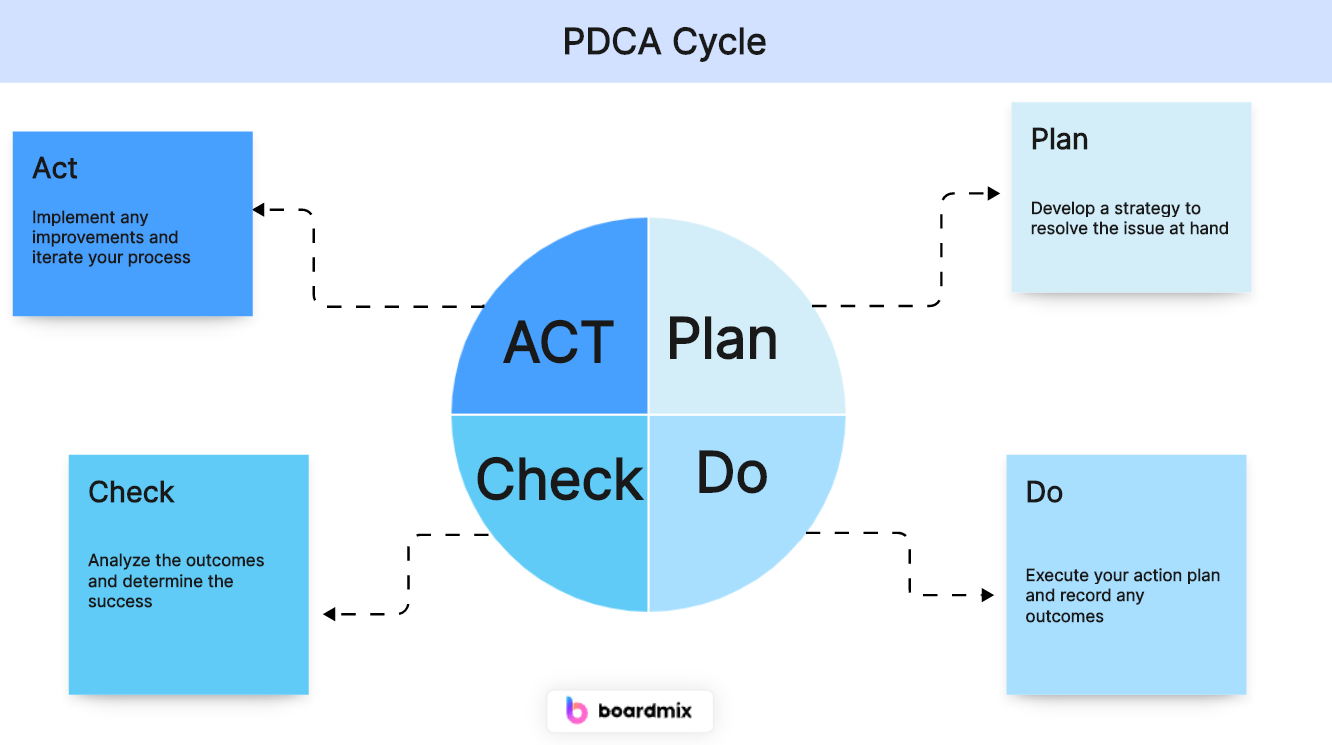

The four stages of the PDCA cycle are:

Plan (P): In this stage, you plan and establish the objectives and processes necessary to deliver results in accordance with the desired outcome. This involves defining the problem, setting goals, and identifying the resources needed.

Do (D): This stage involves implementing the plan and executing the processes. It may include small-scale testing of the plan, collecting data, and making necessary adjustments to improve the process.

Check (C): In this stage, the results of the implemented plan are systematically evaluated. Data is collected and compared against the expected outcomes. This step is crucial for understanding whether the implemented changes have led to the desired improvements.

Act (A): Based on the results of the "Check" stage, actions are taken to standardize the process if it was successful or to modify the plan if improvements are needed. This stage completes the cycle by incorporating lessons learned into future planning and execution.

The PDCA cycle is a continuous and iterative process, and once the "Act" stage is completed, the cycle begins again with new plans and adjustments. The goal is to foster a culture of continuous improvement and learning within an organization, leading to increased efficiency, effectiveness, and overall quality. It is widely used in quality management, process improvement, and other areas where iterative problem-solving and optimization are essential.

Part 2. How Important is the PDCA Cycle in Organizations?

The PDCA cycle is highly important in various fields and industries for several reasons:

Continuous Improvement: The PDCA cycle is a fundamental tool for fostering a culture of continuous improvement within organizations. It encourages the identification of problems, the development of solutions, and the implementation of changes to enhance processes and outcomes.

Problem Solving: The structured approach of the PDCA cycle helps organizations systematically identify and address problems. By following the cycle, teams can analyze root causes, develop effective solutions, and monitor the results to ensure sustained improvements.

Efficiency and Effectiveness: The PDCA cycle is designed to enhance both efficiency and effectiveness. Through the iterative process of planning, doing, checking, and acting, organizations can refine their processes, eliminate waste, and optimize resource utilization.

Risk Management: By regularly assessing and monitoring the results of implemented plans, organizations can proactively manage risks. The PDCA cycle provides a systematic way to identify and address potential issues before they become major problems.

Quality Management: The PDCA cycle is closely associated with quality management principles. It helps organizations establish and maintain high-quality standards by continuously reviewing and improving processes.

Decision-Making Support: The PDCA cycle provides a structured framework for decision-making. It encourages data-driven decision-making by emphasizing the importance of checking and analyzing results before making further adjustments.

The PDCA cycle is a valuable tool for organizations seeking to improve their processes, enhance quality, and adapt to changing circumstances. It supports a proactive approach to problem-solving, learning, and continuous improvement, making it a cornerstone of effective management and quality assurance practices.

Part 3. What Are the Pros and Cons of PDCA Cycle?

Pros of the PDCA Cycle:

Structured Problem-Solving: PDCA provides a systematic and structured approach to problem-solving and improvement, ensuring that issues are identified, analyzed, and addressed in a methodical manner.

Continuous Improvement: The iterative nature of the PDCA cycle promotes a culture of continuous improvement, encouraging organizations to regularly review and enhance their processes.

Data-Driven Decision-Making: PDCA emphasizes the importance of data in decision-making. By collecting and analyzing data at each stage, organizations can make informed decisions based on evidence.

Flexibility: The PDCA cycle is adaptable and can be applied to a wide range of processes and industries. It accommodates changes and adjustments based on the specific needs and challenges of the organization.

Employee Involvement: PDCA encourages the involvement of employees at all levels in the improvement process. This fosters a sense of ownership and engagement among team members.

Cons of the PDCA Cycle:

Time-Consuming: The PDCA cycle, when rigorously applied, can be time-consuming. Collecting and analyzing data at each stage may require significant resources.

Resource Intensive: Implementing the PDCA cycle effectively may require resources in terms of time, personnel, and technology, which may be challenging for smaller organizations with limited resources.

Resistance to Change: Employees and stakeholders may resist the changes introduced through the PDCA cycle, especially if there is a lack of communication or understanding about the benefits of the changes.

Lack of Standardization: The emphasis on continuous improvement may result in a lack of standardization, making it challenging to establish consistent processes and procedures.

Not a One-Size-Fits-All Solution: While PDCA is a versatile tool, it may not be suitable for every situation. Some complex problems may require more specialized problem-solving approaches.

Short-Term Focus: The emphasis on iterative cycles may sometimes lead to a short-term focus, with organizations addressing immediate issues rather than considering long-term strategic goals.

Part 4. How to Apply the PDCA Model?

Applying the Plan-Do-Check-Act (PDCA) model involves a systematic and iterative approach to problem-solving and continuous improvement. Here's a step-by-step guide on how to apply the PDCA model:

1. Plan (P):

Identify the Problem or Opportunity: Clearly define the problem or identify the opportunity for improvement. Be specific and focused on the desired outcome.

Set Objectives and Goals: Establish measurable objectives and goals for the improvement initiative. Define what success looks like and set realistic targets.

Develop a Plan: Devise a plan that outlines the actions required to achieve the objectives. Specify the tasks, responsibilities, resources needed, and a timeline for implementation.

Consider Risks: Identify potential risks and challenges that may arise during the implementation of the plan. Develop strategies to mitigate these risks.

2. Do (D):

Implement the Plan: Execute the plan according to the defined tasks and timeline. Ensure that all team members are aware of their roles and responsibilities.

Document the Process: Keep detailed records of the implementation process. Document any deviations from the plan, unexpected challenges, or lessons learned during the execution.

3. Check (C):

Monitor and Collect Data: Regularly collect data related to the implemented plan. This could include performance metrics, customer feedback, or other relevant information.

Compare Results to Objectives: Compare the collected data against the initially established objectives and goals. Assess whether the implemented changes have led to the desired improvements.

Analyze Variances: If there are variances between expected and actual results, analyze the root causes of the discrepancies. Determine whether adjustments are needed.

4. Act (A):

Take Corrective Actions: Based on the analysis of results, take corrective actions to address any identified issues or variances. Adjust the plan as needed to improve effectiveness.

Standardize Successful Practices: If the implemented changes lead to positive results, consider standardizing these practices to ensure ongoing improvement and consistency.

Reflect and Learn: Reflect on the entire PDCA cycle. Document lessons learned, best practices, and areas for further improvement. Use this knowledge in future planning.

Repeat the PDCA Cycle: Begin a new PDCA cycle based on the lessons learned and insights gained from the previous cycle. Continuously apply the model to drive ongoing improvement.

By following these steps and incorporating the PDCA model into your organization's culture, you can systematically drive improvement and adapt to changing circumstances over time.

Part 5. How to Use PDCA Model with Boardmix?

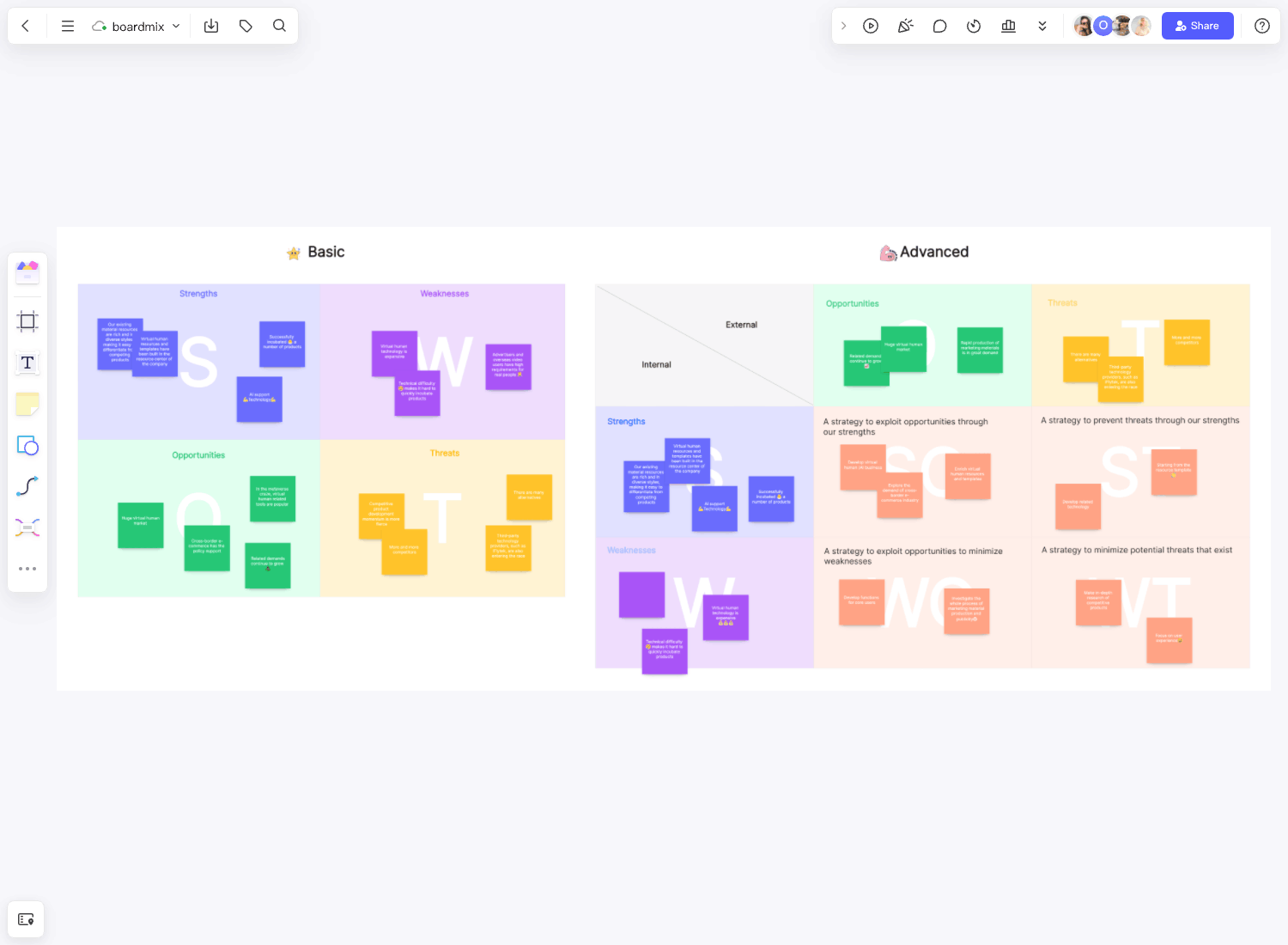

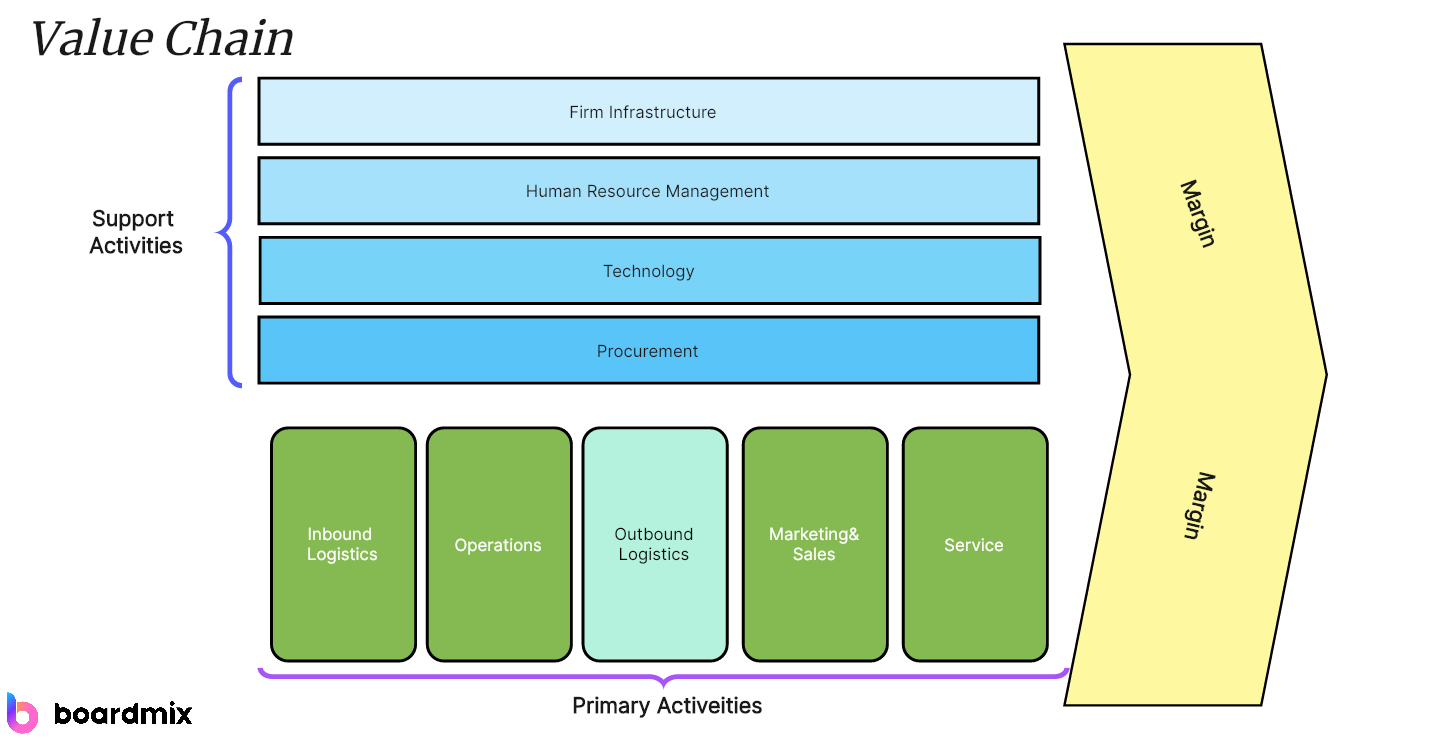

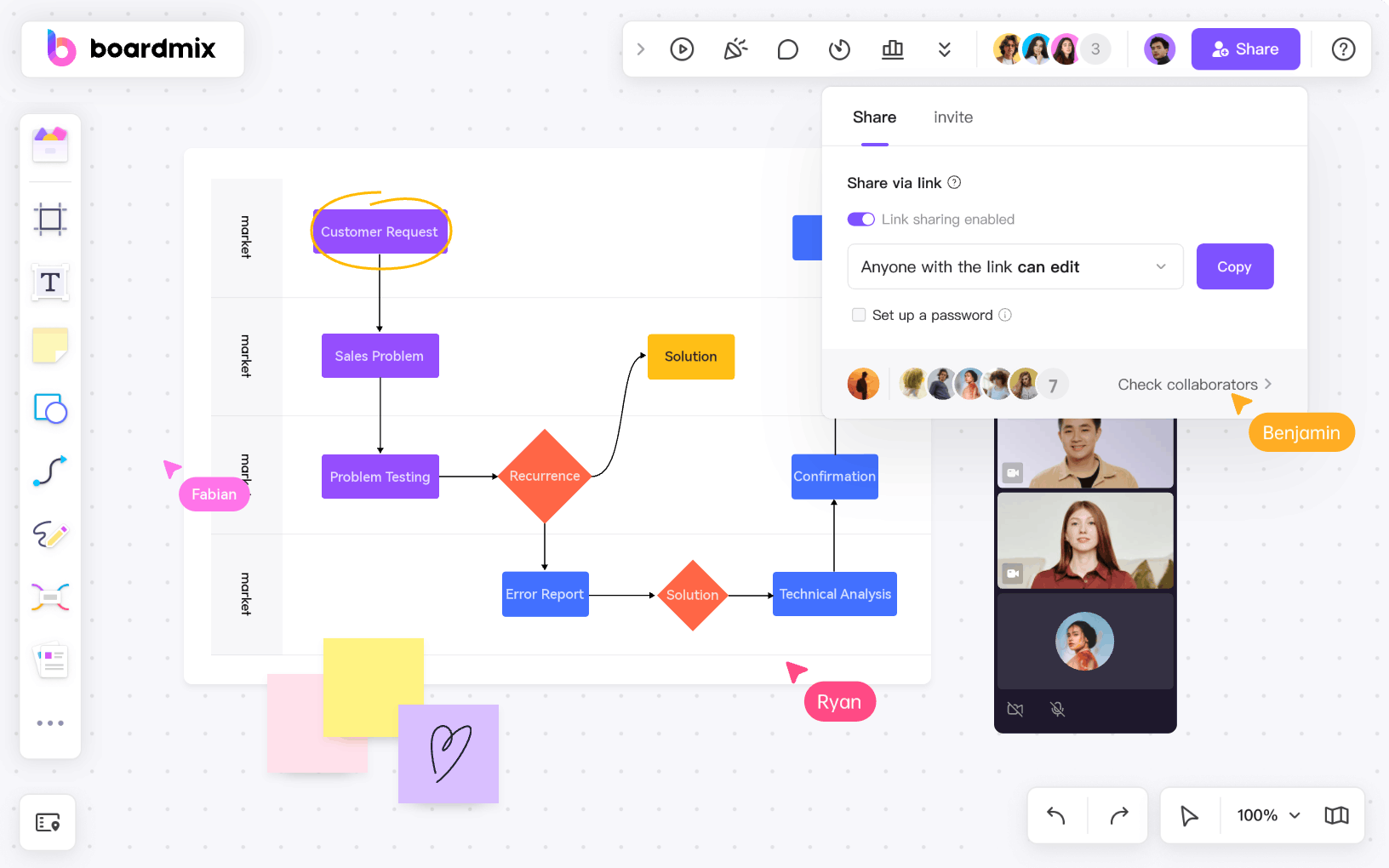

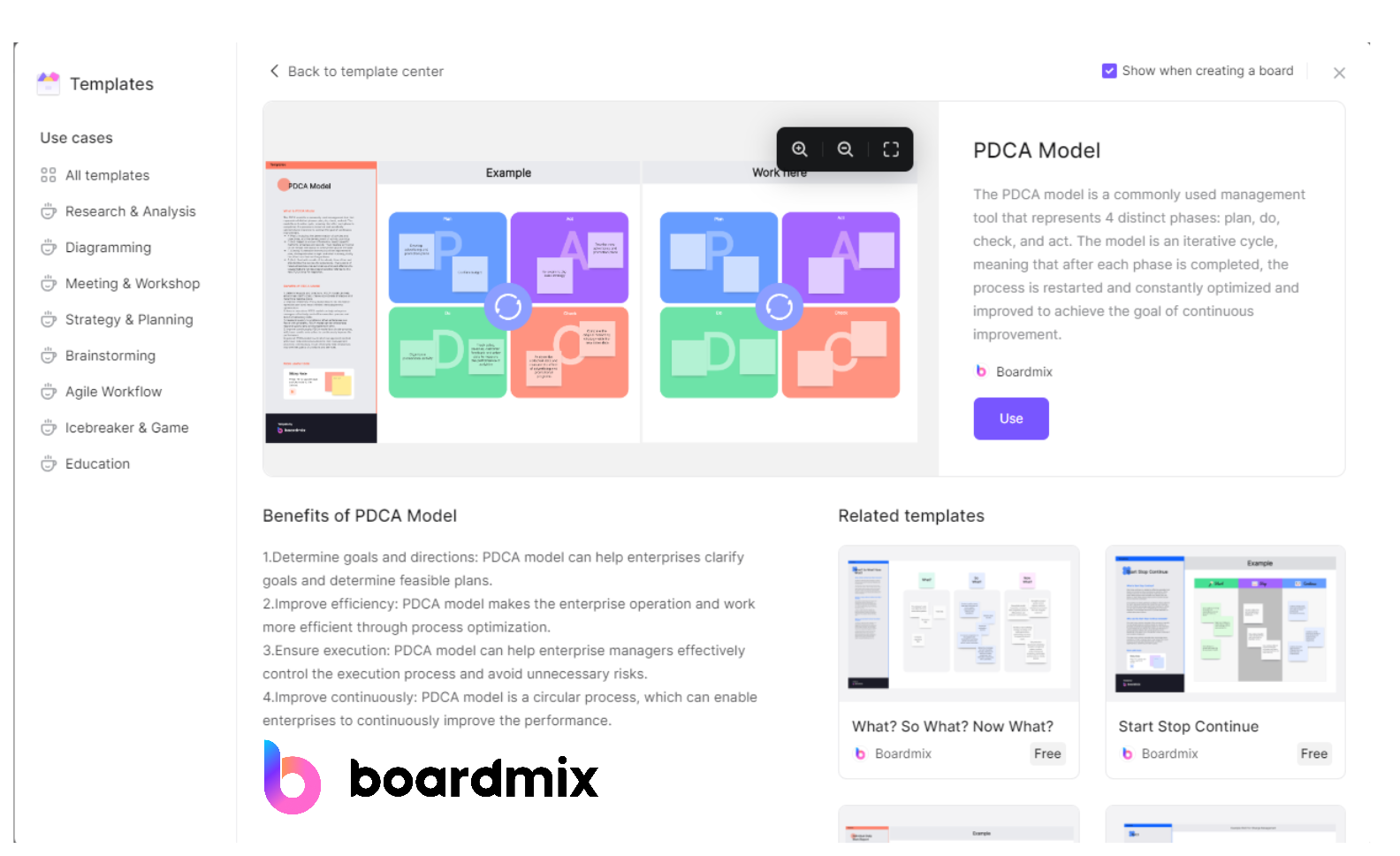

Boardmix is a revolutionary online whiteboard tool designed to streamline your application of the PDCA (Plan-Do-Check-Act) model. With our intuitive interface and extensive library of drawing templates, you can easily visualize each step of the PDCA cycle, fostering better understanding and collaboration among your team. Whether you're planning a new project, implementing changes, checking results or acting on improvements, Boardmix makes it simple to map out your thoughts and ideas in a clear, organized manner. Unlike other tools like Miro or Figjam, Boardmix doesn't require any integrations - everything you need is right at your fingertips. Start using Boardmix today and experience the ease of applying the PDCA model like never before.

Key features of Boardmix:

- Intuitive Interface: Boardmix's user-friendly interface allows users to easily navigate and utilize the platform, even without prior experience.

- Extensive Library of Drawing Templates: With a wide variety of templates available, Boardmix enables users to quickly start their projects without the need for creating designs from scratch.

- Real-time Collaboration: Boardmix supports real-time collaboration, allowing teams to work together simultaneously on the same board, fostering better communication and efficiency.

- No Integration Required: Unlike other online whiteboard tools, Boardmix is a standalone platform that doesn't require any additional integrations, making it more convenient for users.

- PDCA Model Application: Boardmix simplifies the application of the PDCA model by providing visual aids and structured templates that guide users through each step of the process.

FAQs about PDCA Model

1. What is the PDSA cycle?

The PDSA (Plan-Do-Study-Act) cycle is a four-step iterative model for continuous improvement. In the planning phase, goals and strategies are set, followed by small-scale implementation in the doing phase. The study phase involves data collection and analysis to evaluate outcomes. Based on the findings, the act phase includes adjustments to the plan and subsequent implementation of changes. The cycle repeats for ongoing improvement. Similar to PDCA (Plan-Do-Check-Act), PDSA fosters a systematic approach to problem-solving and optimization, emphasizing learning and adaptability in organizational processes.

2. What is the purpose of PDCA in agile?

In Agile methodologies, the PDCA (Plan-Do-Check-Act) cycle, or its close variant PDSA (Plan-Do-Study-Act), serves as a crucial framework for continuous improvement. The purpose of PDCA in Agile is to enable teams to iteratively and incrementally enhance their processes, products, and outcomes.

3. What is the difference between PDCA and agile?

PDCA (Plan-Do-Check-Act) is a general continuous improvement framework applicable across industries, focusing on iterative cycles of planning, execution, evaluation, and adjustment. Agile, on the other hand, is a set of methodologies like Scrum or Kanban, designed specifically for software development and project management. Agile emphasizes iterative, collaborative, and customer-centric approaches. While PDCA offers a broader framework for improvement, Agile provides detailed methodologies with defined roles and practices, initially tailored for the dynamic nature of software development but adaptable to various projects and industries. Both share a commitment to adaptability and continuous enhancement, albeit at different levels of specificity.

Conclusion

The PDCA Cycle serves as a powerful tool for organizations seeking to enhance their processes and achieve continuous improvement. By systematically planning, implementing, checking, and acting on changes, businesses can foster a culture of adaptability and innovation, positioning themselves for long-term success in a dynamic and competitive environment.

Boardmix’s intuitive interface and extensive library of drawing templates make planning, doing, checking, and acting on your projects a breeze. Say goodbye to complicated integrations and embrace a more streamlined, efficient way of working with Boardmix.