5 Why analysis is widely used in various industries, from manufacturing to service sectors, to identify the root cause of problems and implement long-term solutions. It is used to explore the root causes of problems by repeatedly asking the question "Why?" 5 why analysis example is a simple yet effective method to drill down into the details of an issue, uncovering the underlying reasons behind a problem.

What is the Rule of 5 Why Analysis?

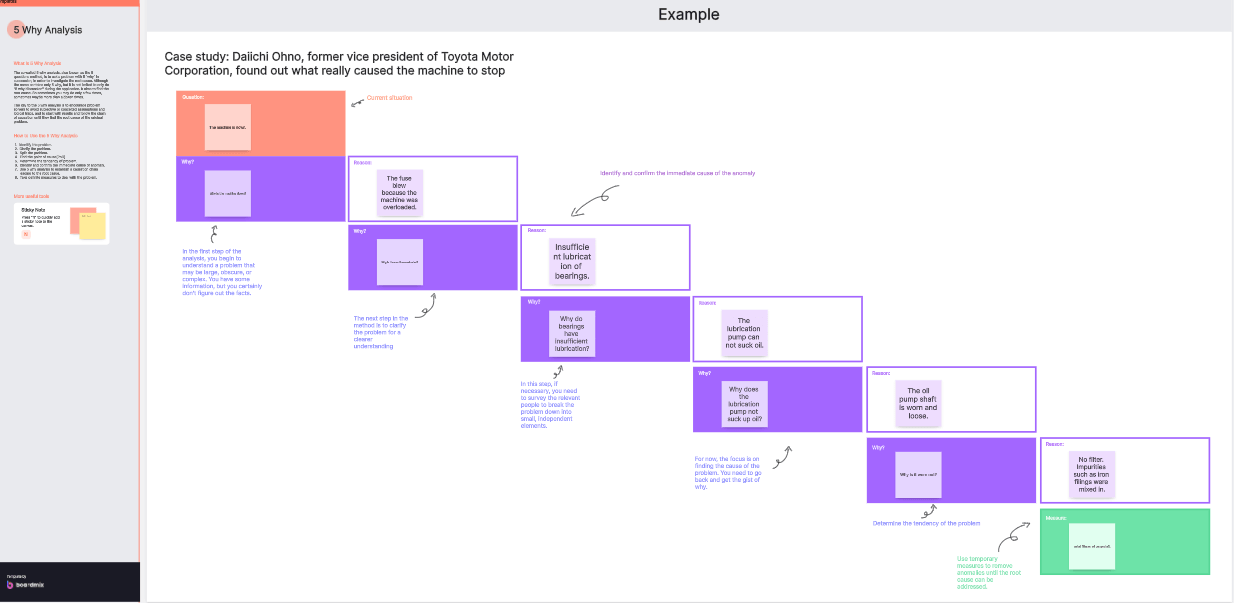

The 5 Why Analysis is based on the principle that asking "Why?" five times can help get to the root cause of a problem. It was originally developed by Sakichi Toyoda, the founder of Toyota Industries, and became a critical component of the Toyota Production System. The technique is now recognized globally as a valuable tool in Lean manufacturing and other problem-solving processes.

View and Edit the 5 Why Analysis Template in Boardmix Template Library👉

The "5" in the 5 Why Analysis example is not a strict rule; sometimes fewer or more questions are needed. The goal is to continue asking "Why?" until the root cause is identified. This method helps to move past symptoms and superficial answers, guiding problem-solvers to the deeper issues that need to be addressed.

For example, if a car won't start, the first "Why?" might reveal that the battery is dead. A second "Why?" might show that the battery is old and needs replacing. A third "Why?" could uncover that the battery's lifespan was shortened because the car's alternator is malfunctioning. By the fifth "Why?", the root cause—perhaps a flaw in the alternator design—might be discovered, leading to a solution that prevents the problem from recurring.

How to Conduct 5 Why Analysis?

Conducting a 5 Why Analysis involves a systematic approach that helps identify the root cause of a problem by repeatedly asking the question "Why?" Here's how you can conduct a 5 Why Analysis:

1. Identify the Problem

Clearly define the problem you're trying to solve. The more specific and clear the problem statement, the more effective your analysis will be. For example, instead of stating "The product is defective," a more specific problem statement might be "The product's battery life is shorter than expected."

2. Assemble the Team

Gather a team of people who are familiar with the problem. This team should include members from different departments or with different perspectives to ensure a comprehensive understanding of the issue. Having diverse viewpoints can lead to a more thorough analysis.

3. Ask the First Why

Begin by asking why the problem occurred. Write down the answer, which will often be a symptom of a deeper issue. For example:

Problem: The product's battery life is shorter than expected.

1st Why: Why is the battery life shorter than expected?

Answer: Because the battery drains quickly.

4. Ask "Why?" Four More Times

Continue to ask "Why?" for each subsequent answer. This helps you dig deeper into the cause of the problem. The process might look like this:

2nd Why: Why does the battery drain quickly?

Answer: Because the software is consuming more power than it should.

3rd Why: Why is the software consuming more power than it should?

Answer: Because the power management settings are not optimized.

4th Why: Why are the power management settings not optimized?

Answer: Because the development team overlooked this aspect during the software design phase.

5th Why: Why did the development team overlook the power management settings?

Answer: Because there was no clear requirement for power optimization in the project specifications.

5. Identify the Root Cause

After the fifth "Why," you should reach the root cause of the problem. In this example, the root cause is the lack of clear requirements for power optimization in the project specifications. Addressing this root cause will prevent the problem from recurring.

6. Develop and Implement Solutions

Once the root cause is identified, brainstorm possible solutions that address the underlying issue. Implement the chosen solution and monitor the situation to ensure that the problem is resolved. In the example, the solution might involve updating the project specifications to include power optimization requirements and providing additional training for the development team.

5 Why Analysis Examples

Here are some examples of 5 Why Analyses, each illustrating how the method can be applied to different scenarios across various industries:

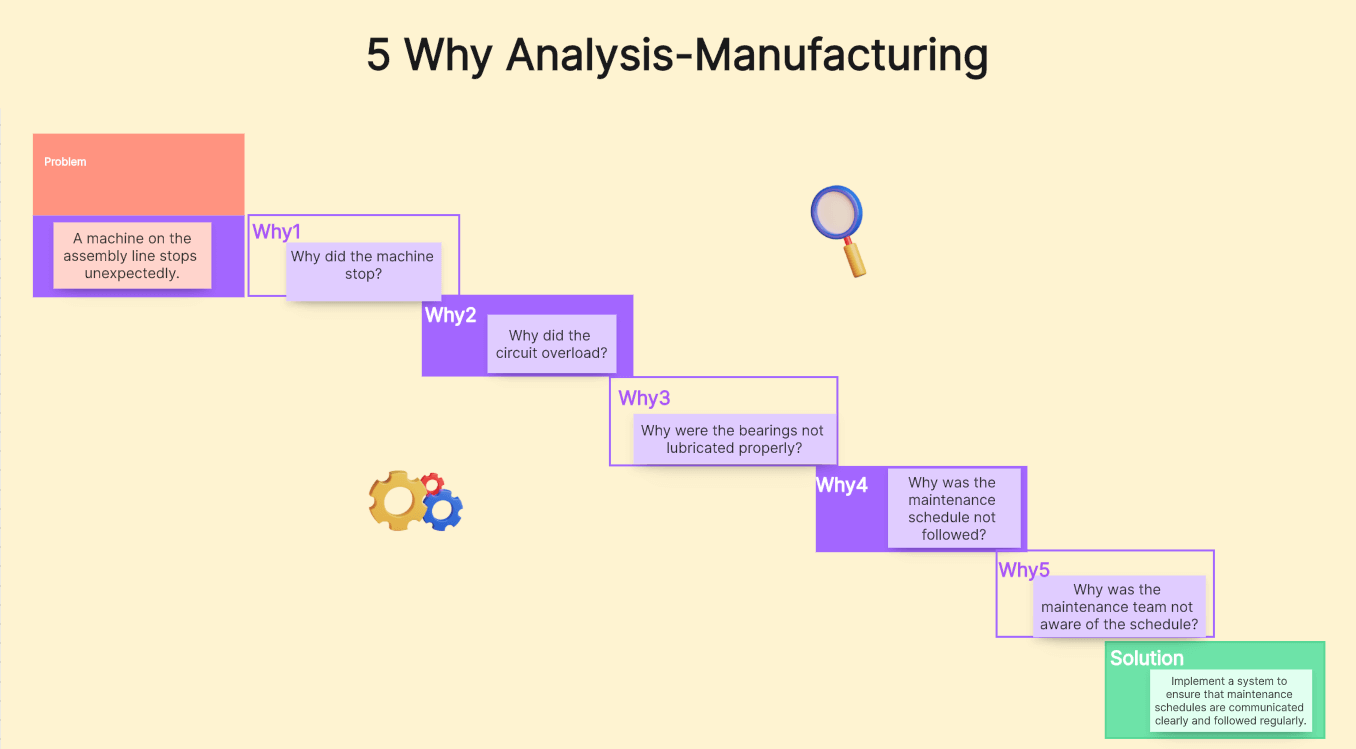

Example 1: Manufacturing

Problem: A machine on the assembly line stops unexpectedly.

Why did the machine stop?

The circuit has overloaded, causing a fuse to blow.

Why did the circuit overload?

The bearings in the machine were not lubricated properly.

Why were the bearings not lubricated properly?

The maintenance schedule was not followed.

Why was the maintenance schedule not followed?

The maintenance team was not aware of the schedule.

Why was the maintenance team not aware of the schedule?

There was no proper communication between the maintenance department and the production team.

Root Cause: The root cause is the lack of communication between the maintenance department and the production team.

Solution: Implement a system to ensure that maintenance schedules are communicated clearly and followed regularly.

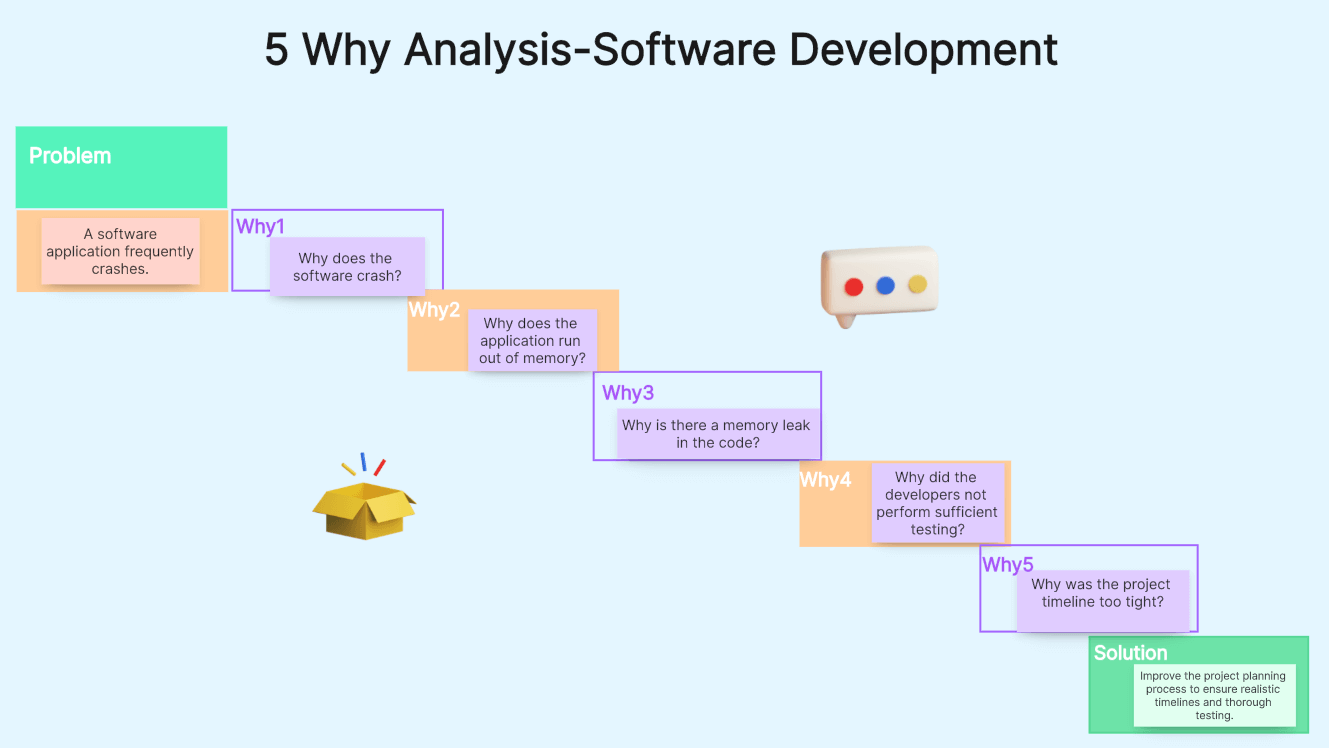

Example 2: Software Development

Problem: A software application frequently crashes.

Why does the software crash?

The application runs out of memory.

Why does the application run out of memory?

There is a memory leak in the code.

Why is there a memory leak in the code?

The developers did not perform sufficient testing.

Why did the developers not perform sufficient testing?

The project timeline was too tight, leading to rushed testing.

Why was the project timeline too tight?

The project was poorly scoped during the planning phase.

Root Cause: The root cause is inadequate project scoping and planning.

Solution: Improve the project planning process to ensure realistic timelines and thorough testing.

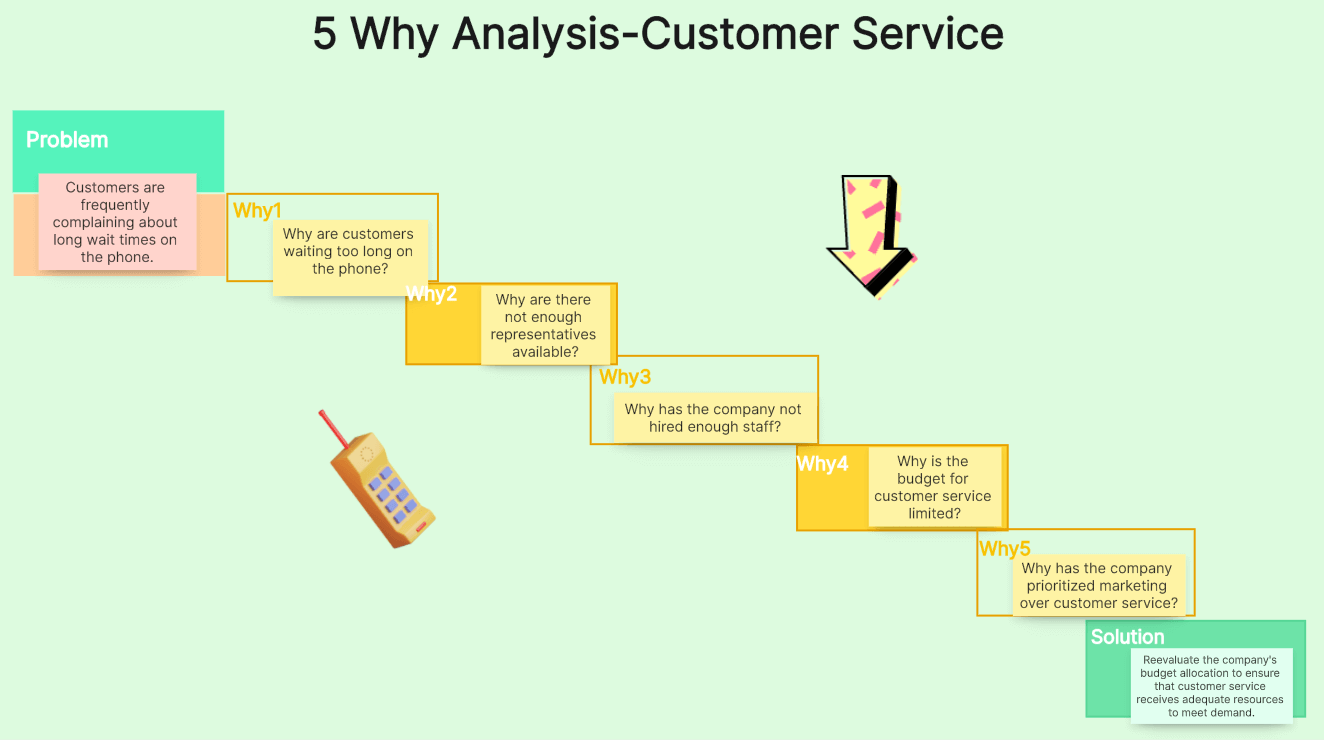

Example 3: Customer Service

Problem: Customers are frequently complaining about long wait times on the phone.

Why are customers waiting too long on the phone?

There are not enough customer service representatives available.

Why are there not enough representatives available?

The company has not hired enough staff.

Why has the company not hired enough staff?

The budget for customer service is limited.

Why is the budget for customer service limited?

The company has allocated more funds to marketing rather than customer service.

Why has the company prioritized marketing over customer service?

There is a belief that marketing will drive more sales, which has overshadowed the importance of customer satisfaction.

Root Cause: The root cause is a strategic decision to prioritize marketing over customer service.

Solution: Reevaluate the company's budget allocation to ensure that customer service receives adequate resources to meet demand.

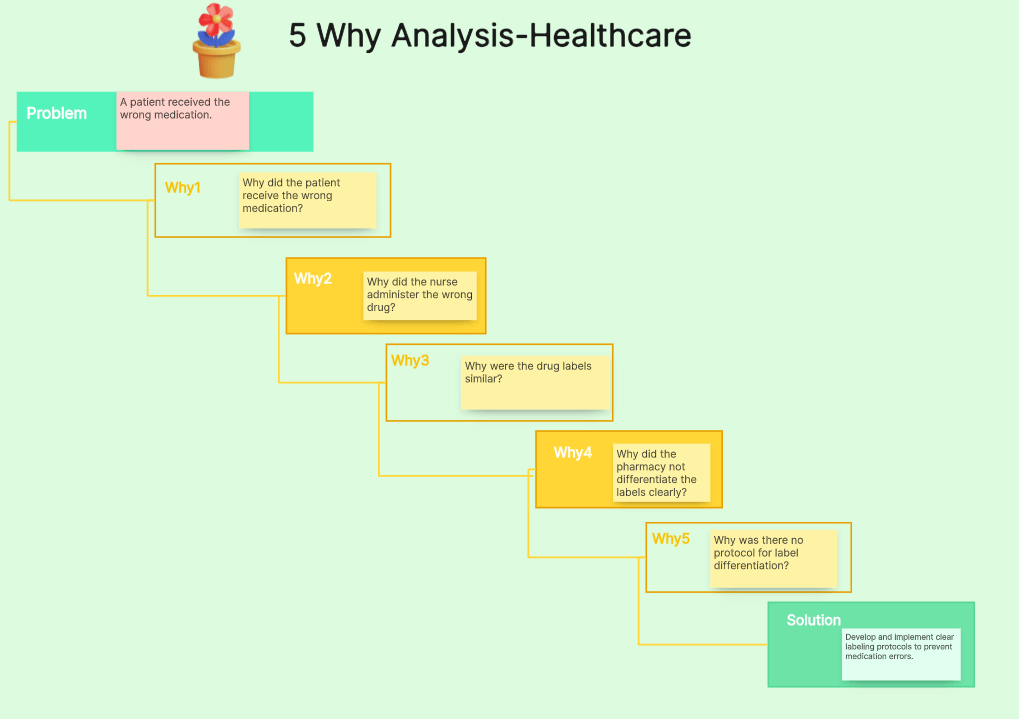

Example 4: Healthcare

Problem: A patient received the wrong medication.

Why did the patient receive the wrong medication?

The nurse administered the wrong drug.

Why did the nurse administer the wrong drug?

The drug labels were similar, leading to confusion.

Why were the drug labels similar?

The pharmacy did not differentiate the labels clearly.

Why did the pharmacy not differentiate the labels clearly?

There was no protocol for label differentiation in place.

Why was there no protocol for label differentiation?

The hospital's safety procedures did not include guidelines for label differentiation.

Root Cause: The root cause is the lack of safety procedures related to label differentiation in the hospital.

Solution: Develop and implement clear labeling protocols to prevent medication errors.

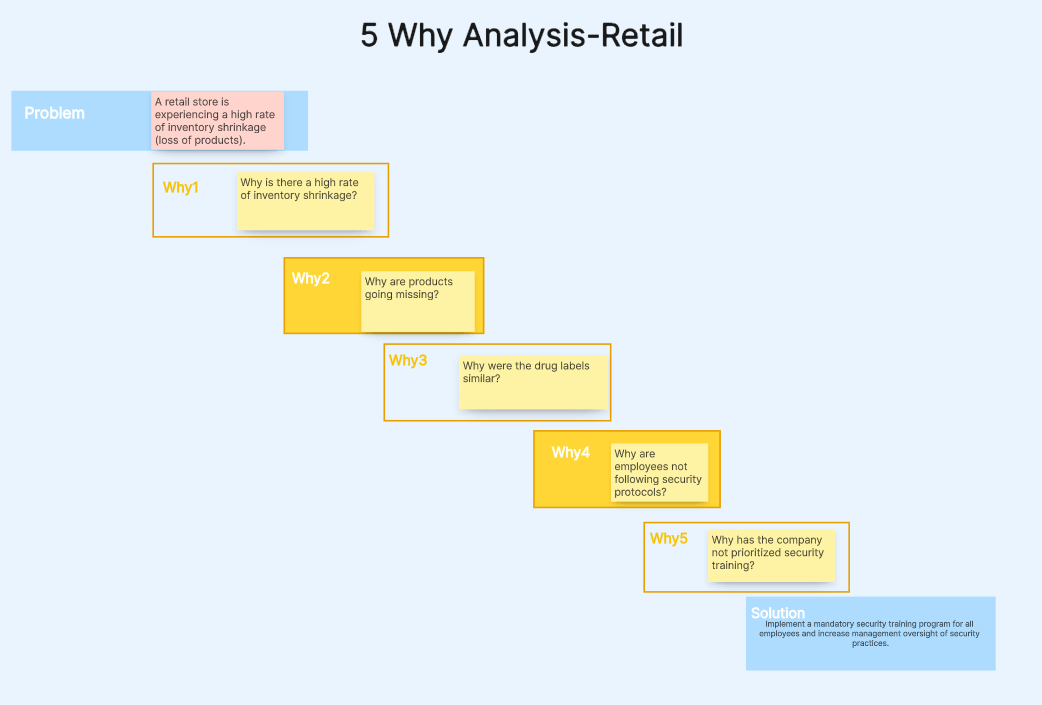

Example 5: Retail

Problem: A retail store is experiencing a high rate of inventory shrinkage (loss of products).

Why is there a high rate of inventory shrinkage?

Products are frequently going missing.

Why are products going missing?

Employees are not consistently following security protocols.

Why are employees not following security protocols?

They have not received proper training on the importance of these protocols.

Why have employees not received proper training?

The company has not prioritized security training.

Why has the company not prioritized security training?

Management was unaware of the extent of the problem.

Root Cause: The root cause is a lack of awareness and prioritization of security training by management.

Solution: Implement a mandatory security training program for all employees and increase management oversight of security practices.

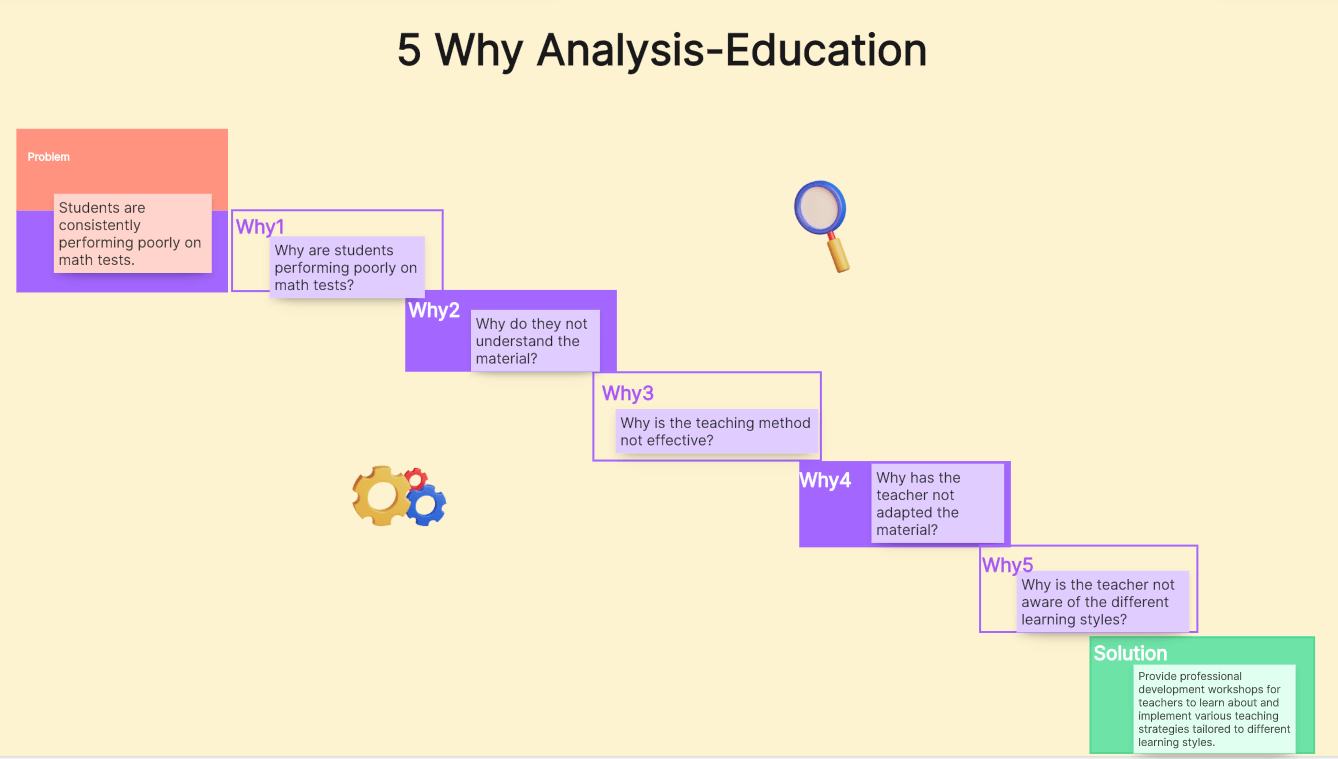

Example 6: Education

Problem: Students are consistently performing poorly on math tests.

Why are students performing poorly on math tests?

They do not understand the material.

Why do they not understand the material?

The teaching method is not effective.

Why is the teaching method not effective?

The teacher has not adapted the material to different learning styles.

Why has the teacher not adapted the material?

The teacher is not aware of the different learning styles.

Why is the teacher not aware of the different learning styles?

There is a lack of professional development opportunities focused on diverse teaching methods.

Root Cause: The root cause is the lack of professional development for teachers on diverse teaching methods.

Solution: Provide professional development workshops for teachers to learn about and implement various teaching strategies tailored to different learning styles.

5 Whys Analysis Frequently Asked Questions

Q1: Can the 5 Why Analysis be used for all types of problems?

A1: While the 5 Why Analysis example is versatile and can be applied to many types of problems, it is particularly effective for problems where the cause is not immediately obvious. For complex problems with multiple contributing factors, other tools such as Fishbone Diagrams or Fault Tree Analysis may be more appropriate.

Q2: What if I reach a root cause before asking "Why?" five times?

A2: The number five is a guideline, not a strict rule. If you reach the root cause before the fifth "Why?", you can stop the analysis. Conversely, if more questions are needed, continue asking "Why?" until the root cause is fully understood.

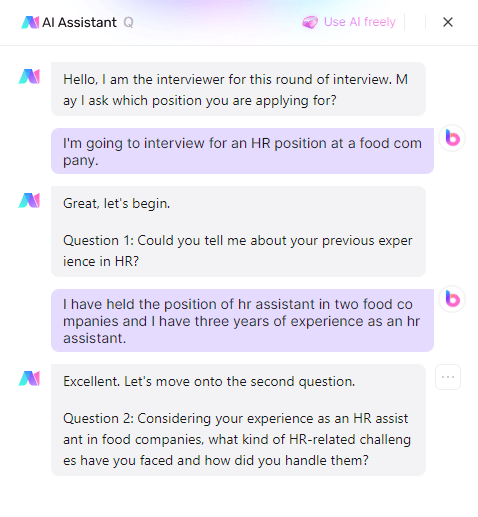

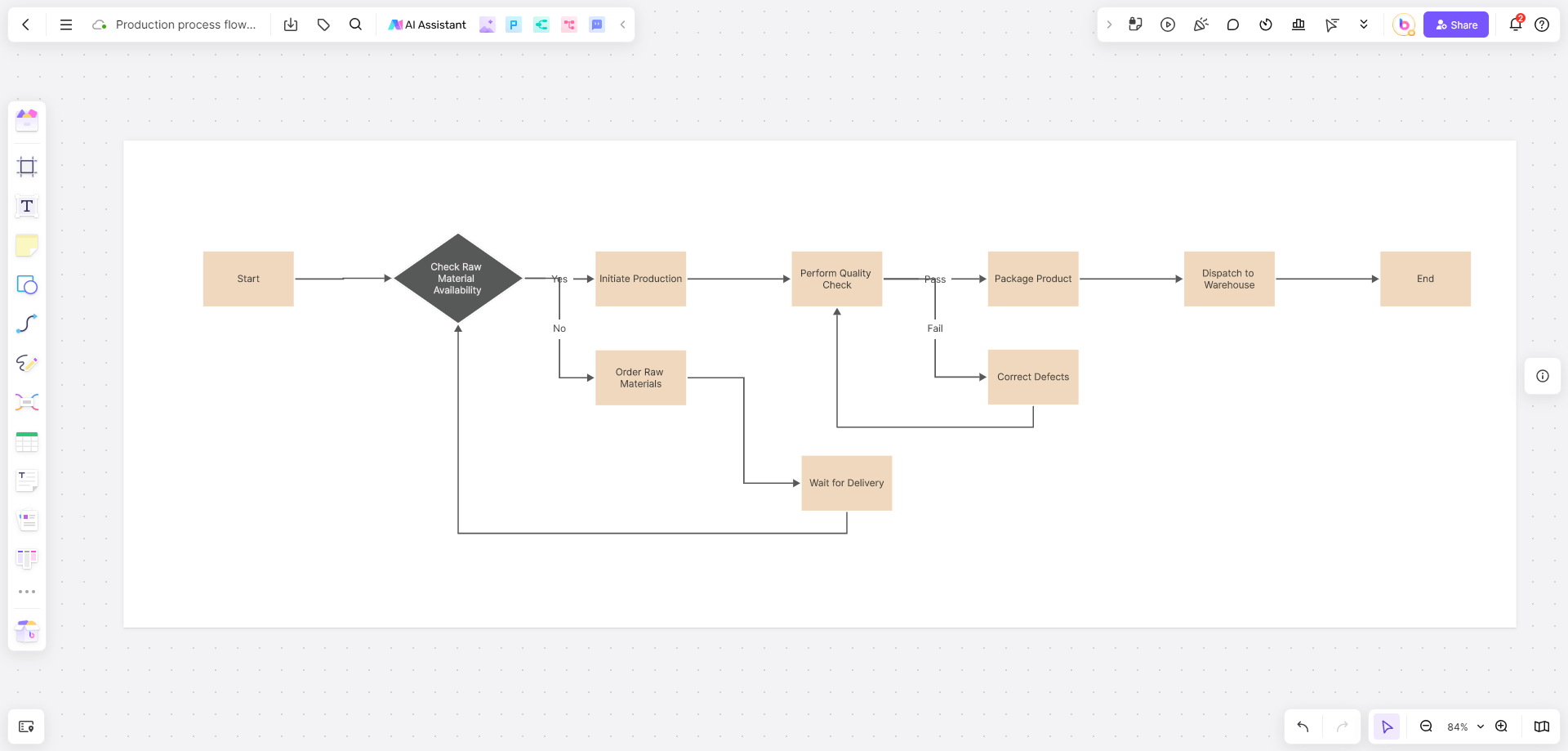

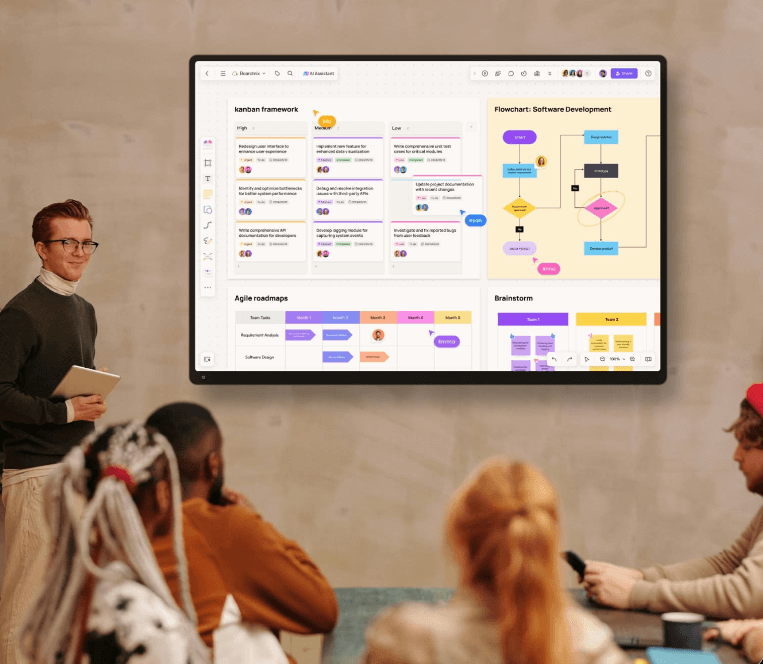

Q3: Which tools can be used for creating 5 why analysis examples?

A3: When it comes to 5 Why Analysis, tools like Boardmix offer a comprehensive solution that combines ease of use, collaboration, and visualization, making it an excellent choice for teams. Boardmix's user-friendly interface and customizable templates make it an excellent choice for conducting detailed 5 Why Analyses. Other tools like Microsoft Visio, Lucidchart, Miro, Draw.io, and XMind also provide valuable features, depending on the specific needs and preferences of your team.

Q4: Can 5 Why Analysis be conducted by an individual, or is a team necessary?

A4: While it can be conducted by an individual, involving a team usually leads to a more thorough analysis. Different perspectives can reveal additional causes or insights that one person might overlook.

By repeatedly asking "Why?" and digging deeper into the issue, teams can identify and address the underlying causes of problems, leading to more effective and lasting solutions. Whether 5 Why analysis example be used in manufacturing, healthcare, service industries, or any other field, the 5 Why Analysis can help organizations move beyond symptoms and implement changes that truly make a difference.