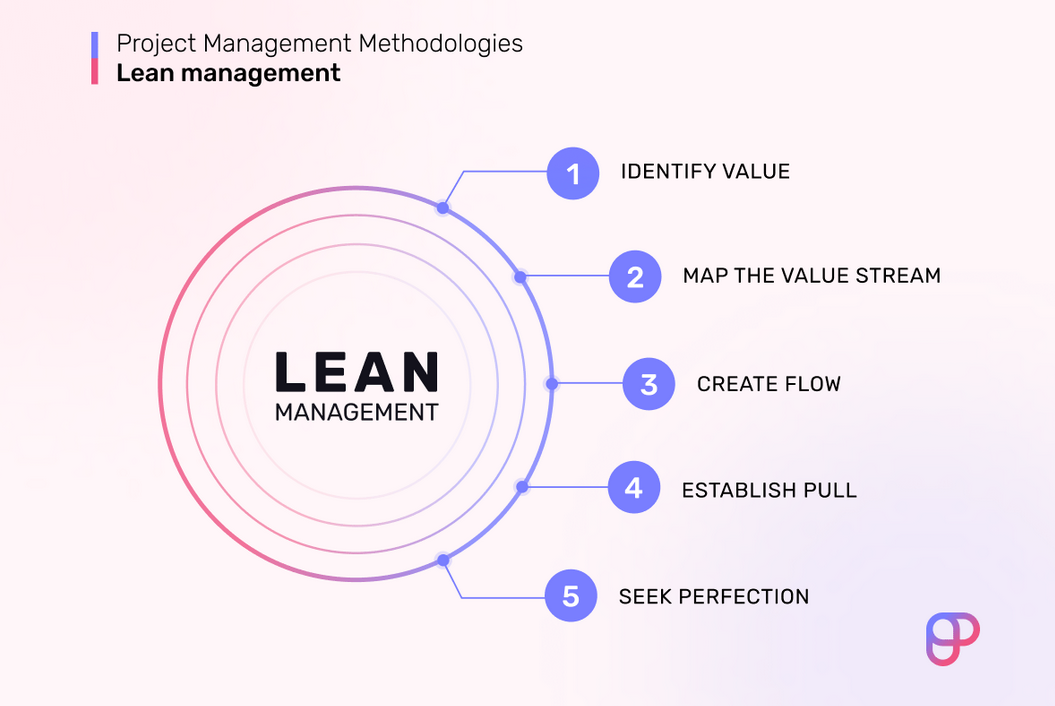

Lean Value Stream Mapping (LVSM) is one of the most effective tools to maximize efficiency and minimize waste in modern business operations. LVSM is an essential practice within Lean management, providing a structured method for analyzing and optimizing the flow of materials and information necessary to deliver a product or service to the customer. This article mainly explores the application of Lean Value Stream Mapping examples and guides you on how to create your own Lean Value Stream Map.

What is Lean Value Stream Mapping?

Lean Value Stream Mapping is a visual tool used in Lean management to analyze and design the flow of materials and information required to bring a product or service to a customer. The primary objective of LVSM is to identify and eliminate waste, thereby enhancing efficiency and value creation.

Key Features✨✨:

Focus on Value: Emphasizes activities that add value to the customer and identifies non-value-adding steps (waste).

Holistic View: Offers a comprehensive overview of the entire process, making it easier to spot inefficiencies and bottlenecks.

Continuous Improvement: Encourages ongoing refinement and optimization of processes to enhance overall efficiency.

By using LVSM, organizations can streamline their operations, reduce costs, and improve quality, all while delivering greater value to their customers.

Value Stream Mapping VS Process Mapping

While both Value Stream Mapping and Process Mapping are essential tools in process improvement, they have distinct differences in terms of their focus, application, and benefits.

Differences:

Focus:

Value Stream Mapping: Focuses on the entire flow of value creation, from the initial supplier to the final customer, identifying both value-adding and non-value-adding activities.

Process Mapping: Concentrates on specific processes or activities within a workflow, detailing every step to understand the intricacies of a particular process.

Application:

Value Stream Mapping: Used primarily in Lean manufacturing and Lean management to provide a high-level view of the entire value stream.

Process Mapping: Applied across various industries and disciplines to document, analyze, and improve specific processes.

Outcome:

Value Stream Mapping: Aims to identify waste and streamline the entire value creation process.

Process Mapping: Seeks to understand and optimize individual processes or tasks.

Tools:

Value Stream Mapping: Utilizes symbols specific to Lean management, such as value-added, non-value-added activities, inventory, and flow.

Process Mapping: Employs general process symbols such as actions, decisions, inputs, and outputs.

While both tools aim to improve efficiency, Value Stream Mapping provides a broader, more strategic view, whereas Process Mapping offers detailed insights into specific processes.

Lean Value Stream Mapping Examples

The application of Lean Value Stream Mapping extends across various industries, each utilizing the tool to enhance efficiency and reduce waste. Here are four examples showcasing its diverse applications:

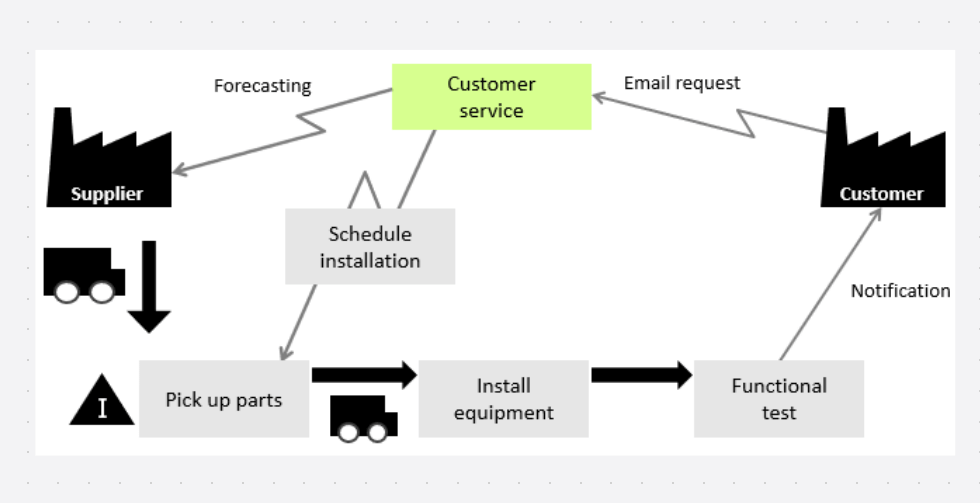

1. Manufacturing Industry Lean Mapping

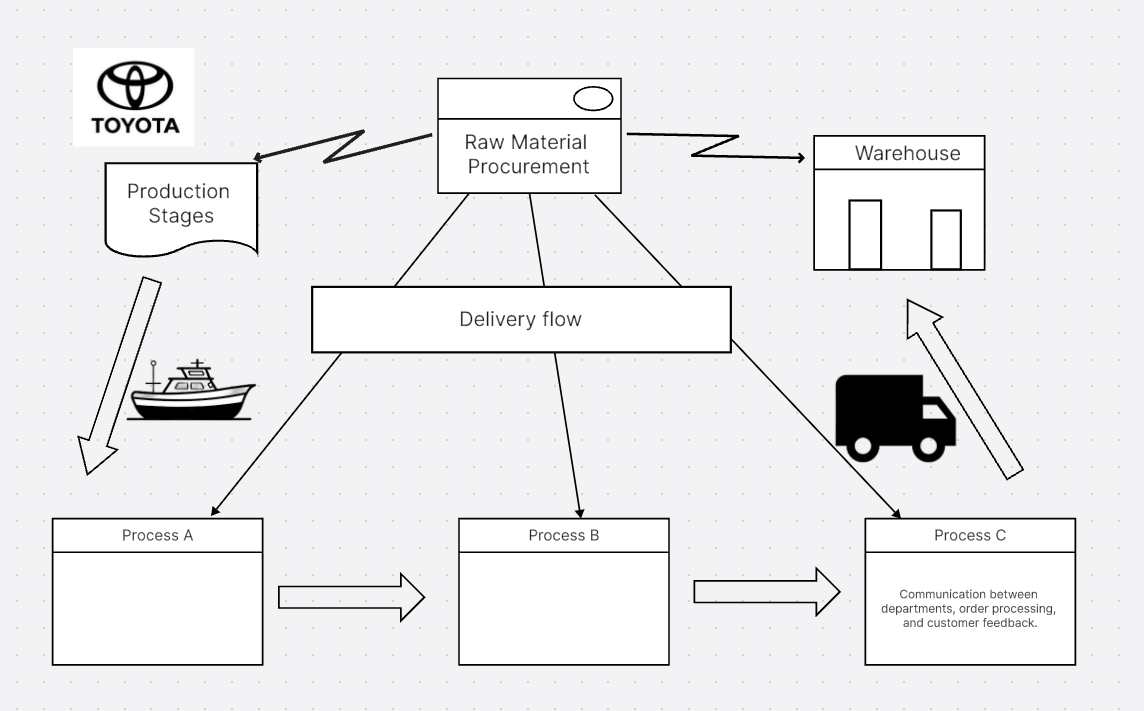

Case Study: Toyota

Toyota employs a Production Process Value Stream Map to optimize its vehicle production line. The map encompasses every stage from raw material procurement to the final assembly and delivery of vehicles. Each process is meticulously documented, highlighting the flow of materials and information.

Detailed Content:

Raw Material Procurement: Shows suppliers, lead times, and inventory levels.

Production Stages: Each stage of assembly, quality checks, and testing.

Information Flow: Communication between departments, order processing, and customer feedback.

Value-Added vs. Non-Value-Added: Differentiation to identify wasteful steps.

By mapping the entire production line, from raw material procurement to the assembly of final vehicles, Toyota identifies bottlenecks and eliminates waste. This approach has enabled Toyota to maintain high-quality standards while reducing lead times and costs.

2. Healthcare Industry Lean Mapping

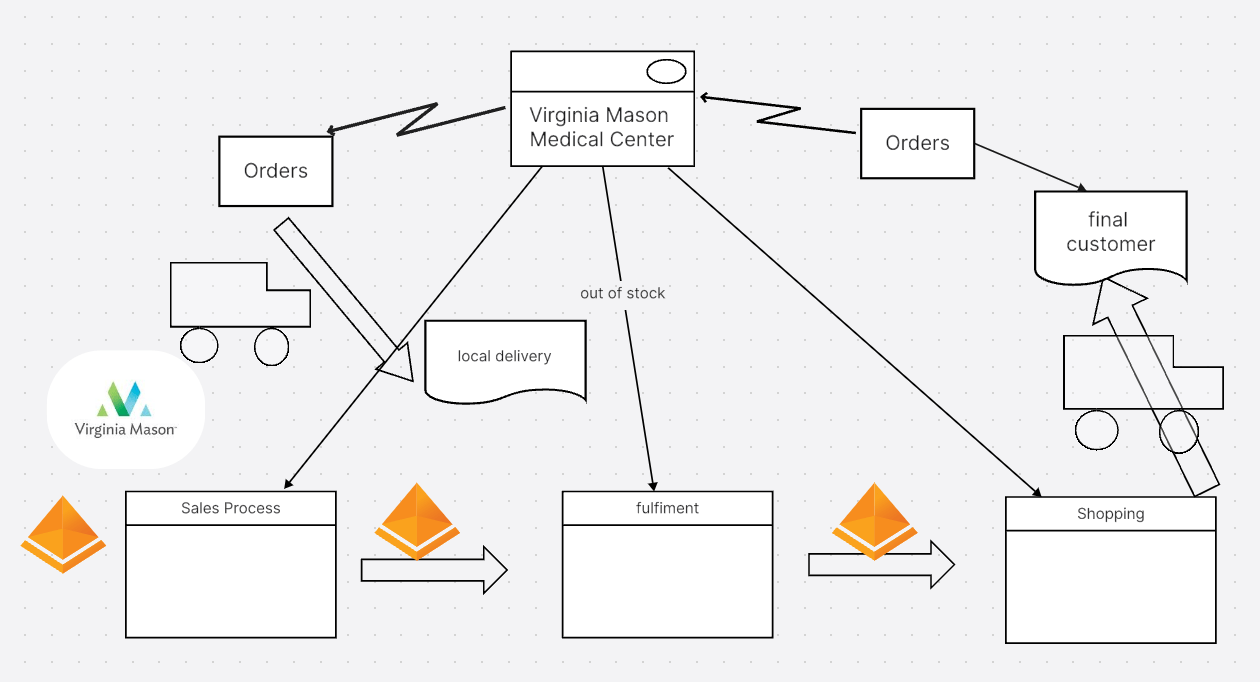

Case Study: Virginia Mason Medical Center

Virginia Mason Medical Center utilizes a Patient Flow Value Stream Map to enhance patient care processes. The map details the entire patient journey from admission to discharge, including touchpoints like the emergency room, nurse stations, consulting time, and surgery preparation.

Detailed Content:

Admission: Steps from patient arrival to registration.

Treatment Phases: ER wait times, consultation durations, diagnostic procedures.

Surgery Preparation and Recovery: Timelines for pre-surgery checks, surgery duration, and post-op care.

Discharge Process: Final evaluations, paperwork, and patient exit.

By mapping the patient journey from admission to discharge, they identified inefficiencies such as long wait times and redundant paperwork. Implementing changes based on their findings resulted in improved patient flow, reduced wait times, and enhanced overall patient satisfaction.

3. Service Industry Lean Mapping

Case Study: Bank of America

Bank of America uses a Loan Processing Value Stream Map to streamline its loan approval process. This map includes every step from loan application submission to final approval, capturing all intermediate activities. By mapping the entire process from application submission to loan approval, the bank identified delays and unnecessary steps. By restructuring the workflow and eliminating redundancies, Bank of America significantly reduced the loan processing time, enhancing customer satisfaction and operational efficiency.

Detailed Content:

Application Submission: Steps for customers to apply for a loan.

Review Stages: Credit checks, risk assessment, and verification procedures.

Approval and Disbursement: Final approval steps and fund disbursement.

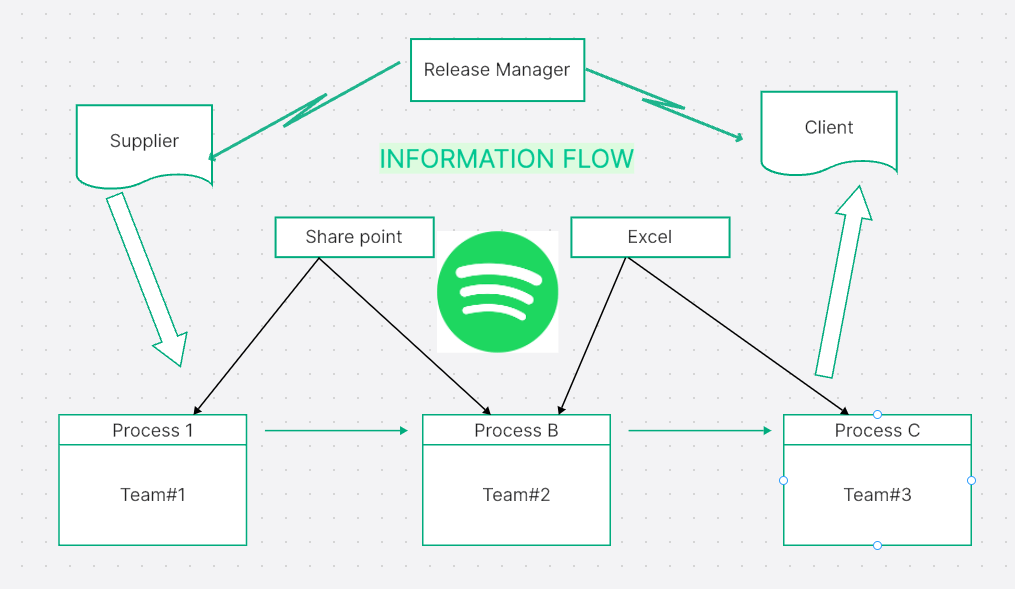

4. Software Development Lean Mapping

Case Study: Spotify

Spotify leverages a Software Development Value Stream Map to optimize its software development lifecycle. This map tracks the flow of work from idea generation to product deployment, including coding, testing, and release stages. By mapping the flow of work from idea generation to product deployment, they identified bottlenecks in the coding, testing, and deployment phases. Streamlining these processes resulted in faster development cycles, allowing Spotify to release updates and new features more rapidly and reliably.

Detailed Content:

Idea Generation: Steps from concept creation to project approval.

Development Phases: Coding, peer reviews, and version control.

Testing: Automated and manual testing stages.

Deployment: Final checks and product release procedures.

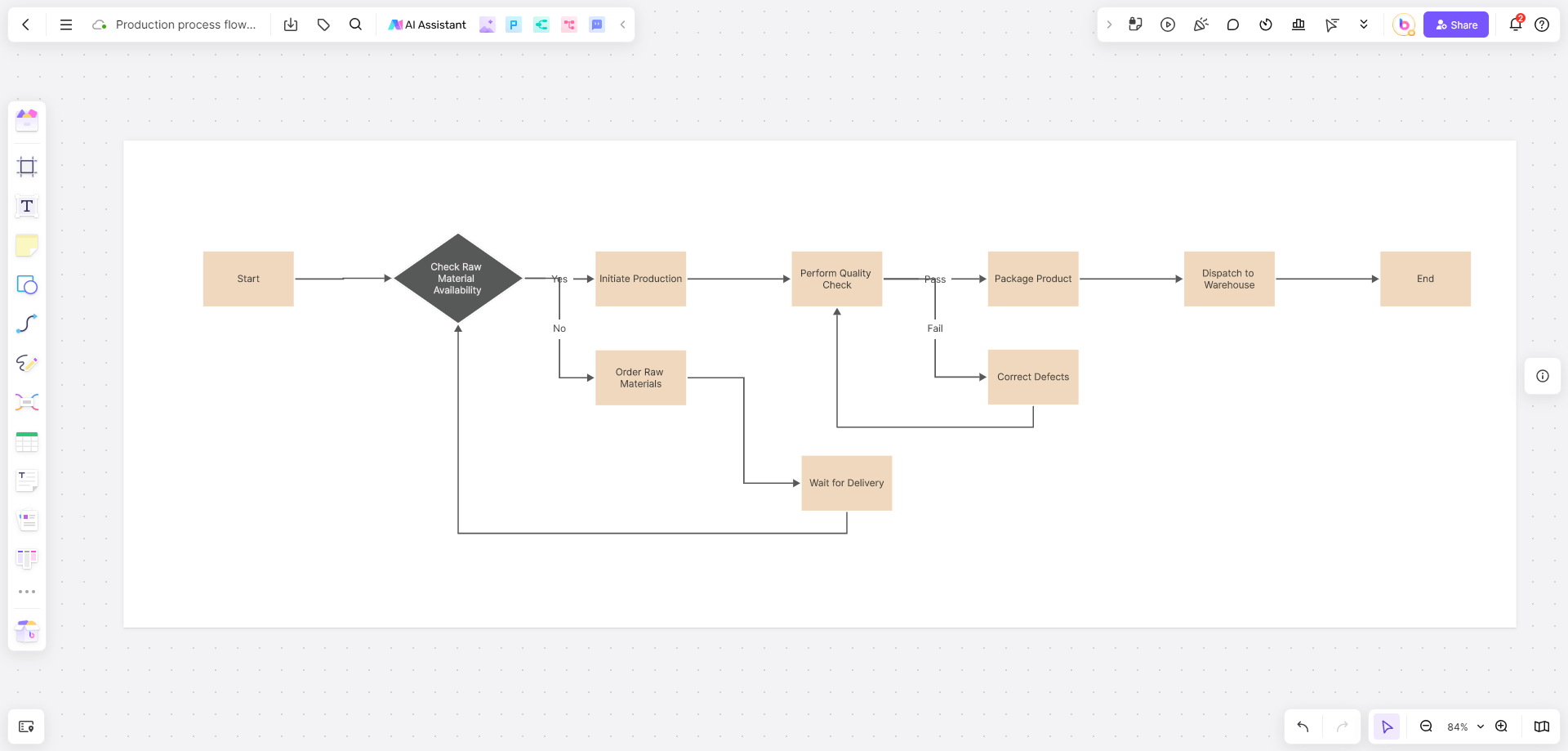

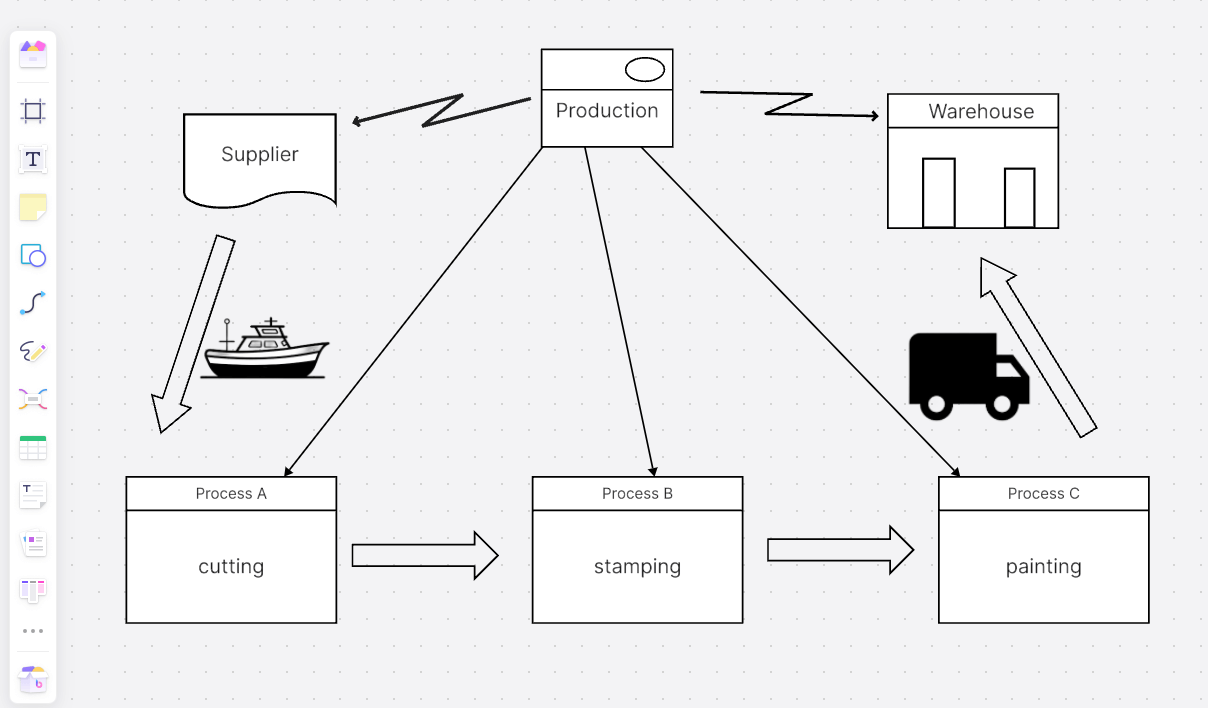

How to Create a Lean Value Stream Mapping?

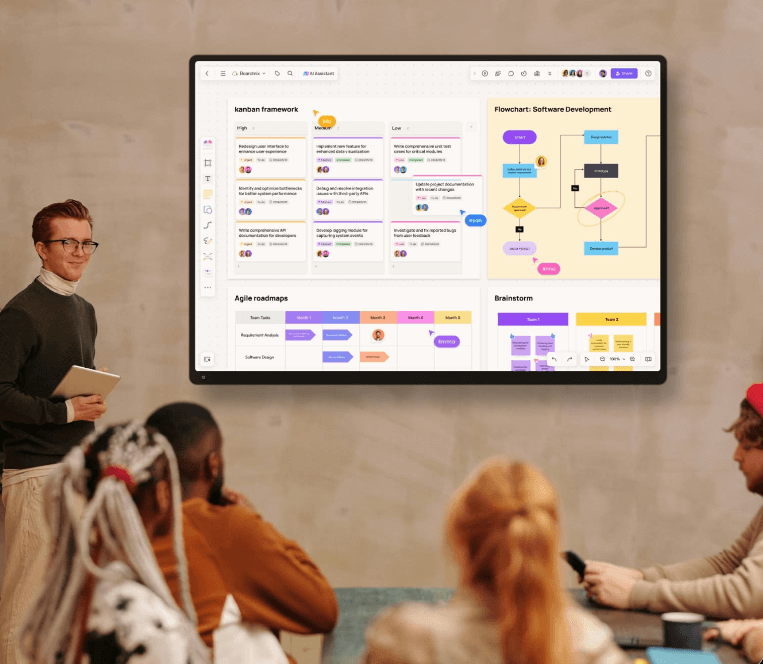

Creating a Lean Value Stream Map can be a straightforward and efficient process, especially with the availability of online tools. One such effective tool is Boardmix, which simplifies the creation and management of Value Stream Maps.

Benefits of Online Value Stream Mapping:

Accessibility: Users can access and work on Value Stream Maps from anywhere with an internet connection, facilitating remote collaboration and global team involvement.

Flexibility: Online platforms often provide user-friendly interfaces with drag-and-drop functionality and predefined symbols, making it easy for users to create and modify maps without extensive training.

Data Integration and Analysis: Built-in analytical tools enable users to analyze metrics such as cycle time, lead time, and value-added vs. non-value-added activities, facilitating data-driven decision-making.

Scalability and Integration with Lean Practices: Online mapping tools can scale with organizational growth and evolving process needs, accommodating larger projects and expanding teams. Aligns with Lean principles by promoting continuous improvement, waste reduction, and value creation through visual management and process transparency.

Steps to Create a Lean Value Stream Map Using Boardmix:

1. Start a New Project:

Visit the Boardmix website and sign up for an account or log in if you already have one. Then, click on "Create New Project" and select "Value Stream Mapping" from the template options.

2. Define the Scope:

Clearly define the boundaries of your value stream. Decide where the process begins (e.g., from raw material acquisition or customer order) and where it ends (e.g., delivery to the customer).

3. Map the Current State:

Use Boardmix’s intuitive interface to map the current state of your process. Add all relevant steps, from supplier inputs to customer delivery, using standardized symbols.

-Activities: Value-adding and non-value-adding activities.

-Inventory: Raw materials, work in progress, and finished goods.

-Information Flow: Communication channels, data inputs, and outputs.

-Metrics: Time metrics such as lead time, cycle time, and processing time.

4. Identify Waste and Inefficiencies:

Analyze the current state map to identify areas of waste, bottlenecks, and inefficiencies. Boardmix may provide specific symbols or tools to highlight these areas.

5. Design the Future State Map:

Based on your analysis, design the future state map. Implement improvements and changes to eliminate identified waste and optimize the flow of materials and information.

6. Develop an Implementation Plan:

Incorporate metrics such as cycle time, lead time, and inventory levels into your map. Use annotations to provide additional context or explanations where necessary. Once feedback is incorporated and the map is finalized, outline an implementation plan for transitioning from the current state to the future state. Assign responsibilities and set timelines directly within Boardmix. Assign tasks and set deadlines within Boardmix for accountability.

7. Monitor and Adjust:

Use Boardmix’s collaboration features to track progress and make necessary adjustments. Regularly review the map and refine the process as needed.

By following these steps, you can effectively create and implement a Lean Value Stream Map using Boardmix, leading to improved efficiency and reduced waste in your operations.

Lean Value Stream Mapping is a powerful tool for any organization aiming to enhance efficiency, reduce waste, and deliver greater value to its customers. By learning the related knowledge of lean mapping and utilizing tools like Boardmix for creating your own maps, you can harness the full potential of LVSM. Embrace this practice to drive continuous improvement and operational excellence in your organization.