SIPOC and Value Stream Mapping (VSM) are two indispensable tools for process optimization and lean management. SIPOC helps us quickly sort out the boundaries and key elements of the process from a high-level perspective, while value stream mapping digs deep into the details of the process, identifies waste and designs optimization solutions.

So, how can we combine SIPOC and VSM to maximize their value? Here, we will explore how to apply SIPOC to value stream mapping through cases and improve process management efficiency.

What is SIPOC?

SIPOC is a process analysis tool, which stands for the acronyms of the following five English words:

- Supplier: Who provides resources?

- Input: What resources are needed? (such as materials, information, data)

- Process: What specific steps are taken?

- Output: What results are delivered in the end?

- Customer: Who receives the results?

In short, SIPOC is like a map, which helps you quickly see the "starting point → process → end point" of a process, and clearly understand who is involved, what is needed, and what is produced.

What is Value Stream Mapping (VSM)?

If you have ever felt that your workflow is complicated, inefficient, or always dragged down by various wastes, then Value Stream Mapping (VSM) may be a tool you need to know.

The main tasks of the value stream map are the following three points: draw all the steps of the current process, then find out the wasteful links, and finally design a more efficient future process.

When using the valus stream mapping, the core of the value stream map is to only keep the steps that are valuable to customers and cut out useless links. In other words, all steps that are not customer-oriented are wasteful. In this way, you can make the process more streamlined and efficient.

Value Stream Map Case: Producing a Bicycle

Let's use a simple example to illustrate how the value stream map works.

1. Current Process

Suppose you are now responsible for producing bicycles. The current process may be as follows:

- Design: Design bicycles according to customer needs;

- Purchase parts: Purchase parts from suppliers;

- Assembly: Assemble parts into bicycles;

- Quality inspection: Check whether the bicycles meet the standards;

- Inventory: Store bicycles in the warehouse;

- Delivery: Deliver bicycles to customers.

2. Waste Point Analysis

In this process, you may find the following wastes:

Inventory waste: Bicycles are piled up in the warehouse, taking up space and money;

Time waste: The quality inspection link takes too long, resulting in reduced overall efficiency.

3. Optimization plan

Through the value stream map, you can design a more efficient future process:

Reduce inventory: Adopt the "on-demand production" model to reduce inventory backlogs;

Merge quality inspection steps: Merge the quality inspection link with the assembly link to shorten waiting time.

Case Study: How to Apply SIPOC in Value Stream Mapping?

If you are learning process optimization, you can use SIPOC and value stream mapping (VSM) together to achieve better results. Next, we will introduce how to use SIPOC in value stream mapping and make these two tools your partners in process optimization.

1. Use SIPOC to clarify process boundaries

Before you start drawing a value stream map, use SIPOC to help you clarify the boundaries of the process. SIPOC is like a "map outline" that helps you quickly answer the following questions:

- What is the starting point and end point of the process?

- What are the key inputs and outputs?

- What internal or external suppliers and customers are involved?

Why is this important?

Value stream mapping can involve a lot of details, and without clear boundaries, it is easy to get lost in the complexity of the process. SIPOC helps you define the scope and ensure that you don't miss key links or get bogged down in unnecessary details.

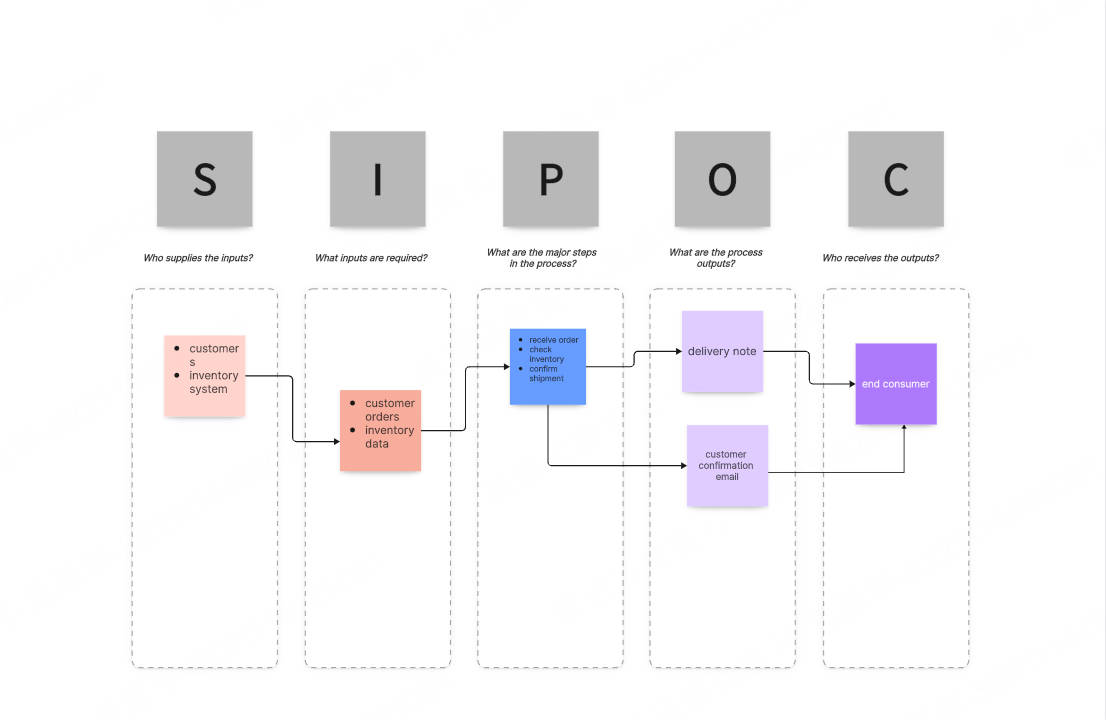

For example:

Suppose you want to optimize an order processing process, SIPOC will help you clarify:

- Suppliers: customers, inventory system;

- Input: customer orders, inventory data;

- Process: receive order → check inventory → confirm shipment;

- Output: delivery note, customer confirmation email;

- Customer: end consumer, logistics team.

With this information, you can draw a value stream map more clearly.

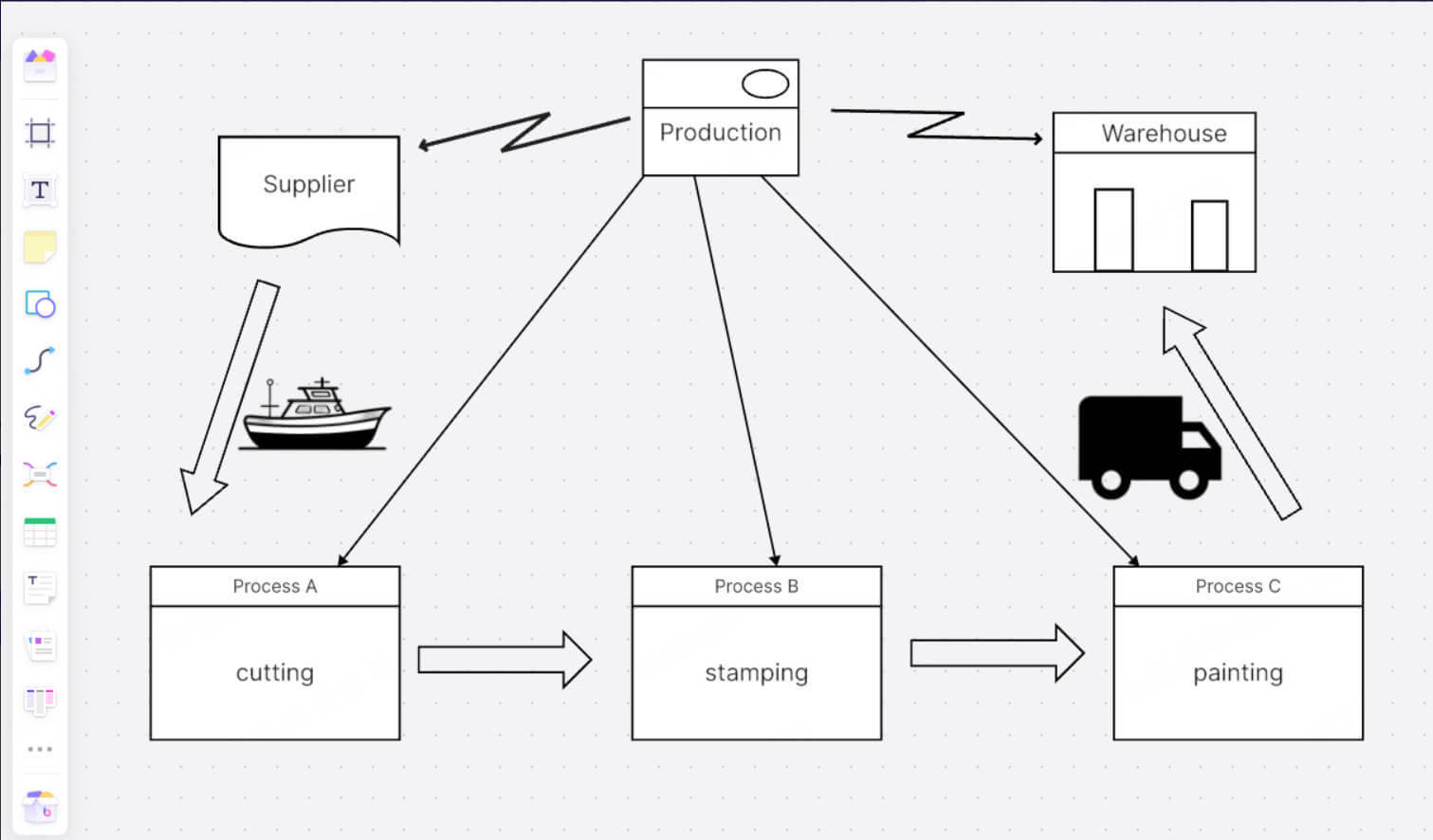

2. Consider the SIPOC elements in VSM

When drawing a value stream map, you can incorporate SIPOC elements into it and mark each link:

- Input (such as raw materials, order information);

- Supplier (who provides input);

- Output (such as semi-finished products, reports);

- Customer (who receives output).

The benefit of doing this is to make the ins and outs of each step clearer and help you better understand the dependencies in the process.

For example:

In the production process, the input of a certain link is parts (from supplier A) and the output is assembled products (handed over to the quality inspection department). By marking this information, you can see the flow of materials and information more clearly.

3. Use SIPOC to check waste

When analyzing the value stream map, SIPOC can help you identify waste more efficiently. For each step, ask yourself:

Is the input of this link necessary? Is the supplier reliable?

Does the output meet customer needs? Is there any over-processing?

For example:

If you find that a certain link has input of excess packaging materials (waste), you can optimize the supplier selection and reduce unnecessary input;

If the customer does not need a certain report (redundant output), you can directly delete the step.

4. Use SIPOC to verify feasibility when designing the future state

When you design the optimized future process, SIPOC can help you verify whether the process is feasible:

Can the new supplier provide stable input?

Does the output still meet customer needs?

For example:

If you plan to reduce inventory, you need to ensure that the supplier can provide parts in time and the customer can still receive the product on time. With SIPOC, you can quickly check whether these key points are met.

SIPOC vs. VSM: Differences and Connections

Although both SIPOC and VSM are process analysis tools, their functions are slightly different:

SIPOC: is more like a high-level "process snapshot", suitable for quickly sorting out the boundaries and key elements of the process;

VSM: is a more detailed and dynamic "flowchart", including details such as time, data, and waste analysis.

Just like building a house, SIPOC is a design sketch (marking the room functions, door and window locations), while VSM is a construction blueprint (marking the water pipe circuits, material usage).

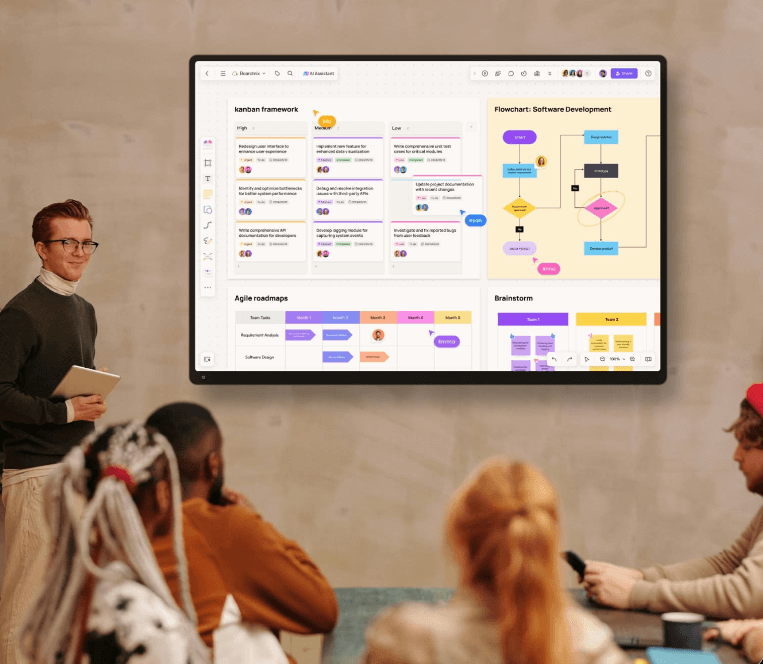

Exploring SIPOC & Value Stream Mapping with Boardmix

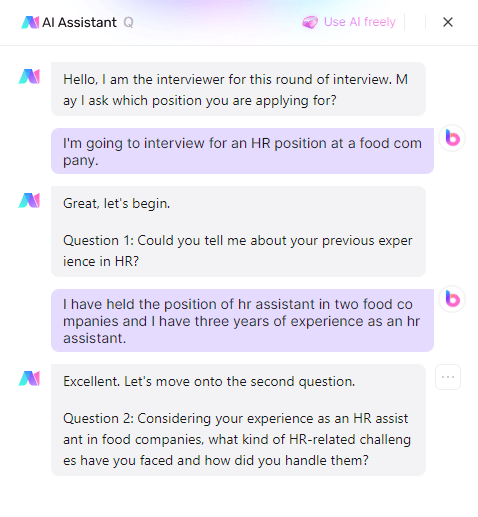

Looking for a powerful yet easy-to-use tool to create SIPOC and Value Stream Maps? Boardmix online whiteboard is your perfect choice. Designed for seamless process visualization and optimization, Boardmix helps you analyze workflows, identify inefficiencies, and develop improvement strategies with ease. Let’s explore how Boardmix makes SIPOC and VSM mapping more efficient and intuitive.

Why Boardmix Stands Out for Process Mapping?

Before we dive in, here are some key highlights of Boardmix:

Real-time collaboration for teamwork: Multiple users can edit simultaneously and collaborate instantly with team members.

AI-powered diagramming: Integraed with advanced AI tool for AI-generated diagrams, AI-generated image, AI-text optimization, and more to elevate efficiency.

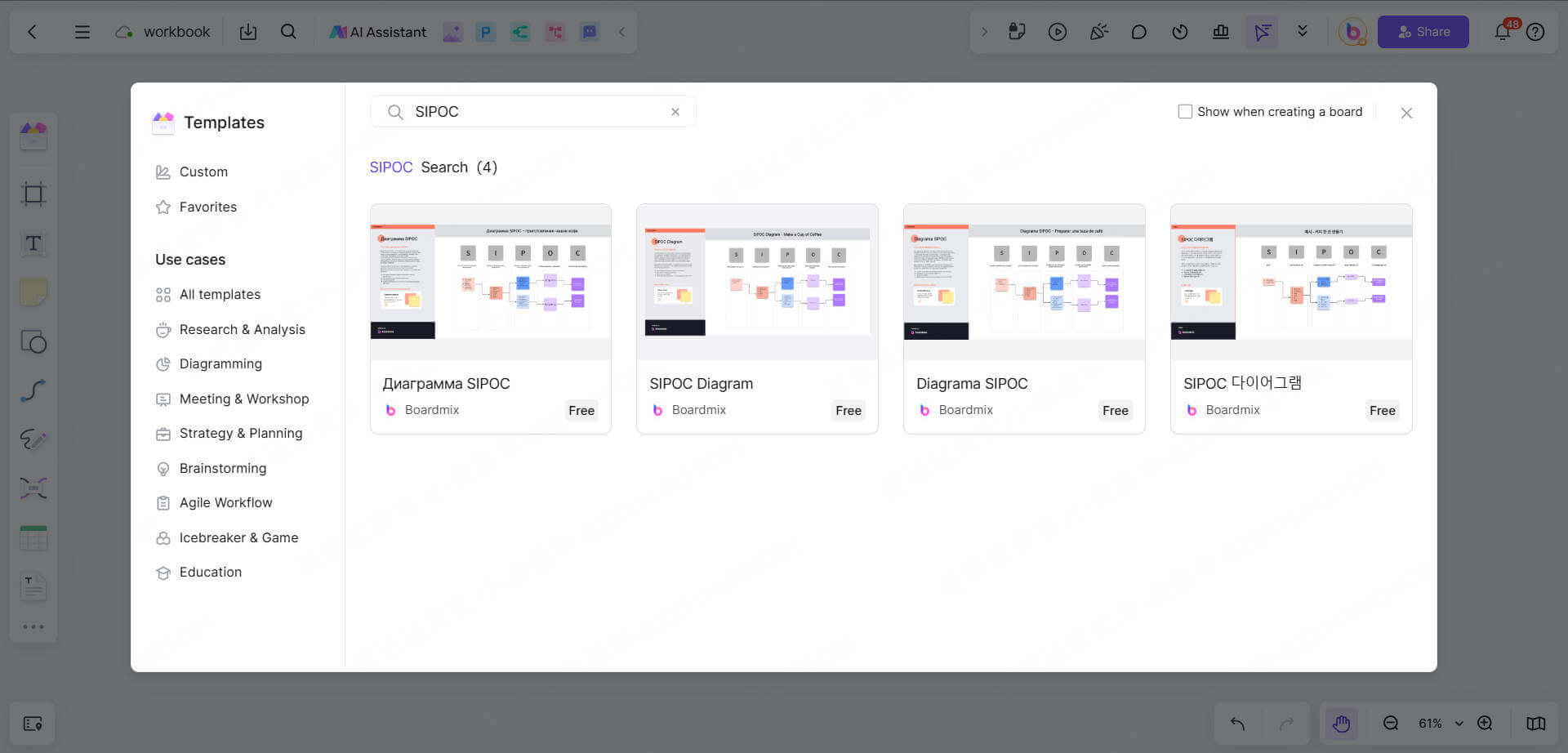

Diverse well-designed templates: Pre-built SIPOC and VSM templates for quick setup.

User-friendly design: Drag-and-drop interface for effortless mapping.

Cross-platform access: Available on web and mobile, so you can works seamlessly on desktop, tablet, and mobile.

Advanced data visualization: Customizable charts, color coding, and annotations for clear insights.

Cloud-based storage: Access your diagrams anytime, anywhere.

Integration with diverse diagrams: Add flowcharts, mind maps, and Gantt charts for a holistic process overview.

Enterprise-level security: Ensures data encryption and secure access.

With these features, Boardmix not only simplifies diagram creation but also makes process optimization smoother and more efficient.

Creating a SIPOC Diagram with Boardmix

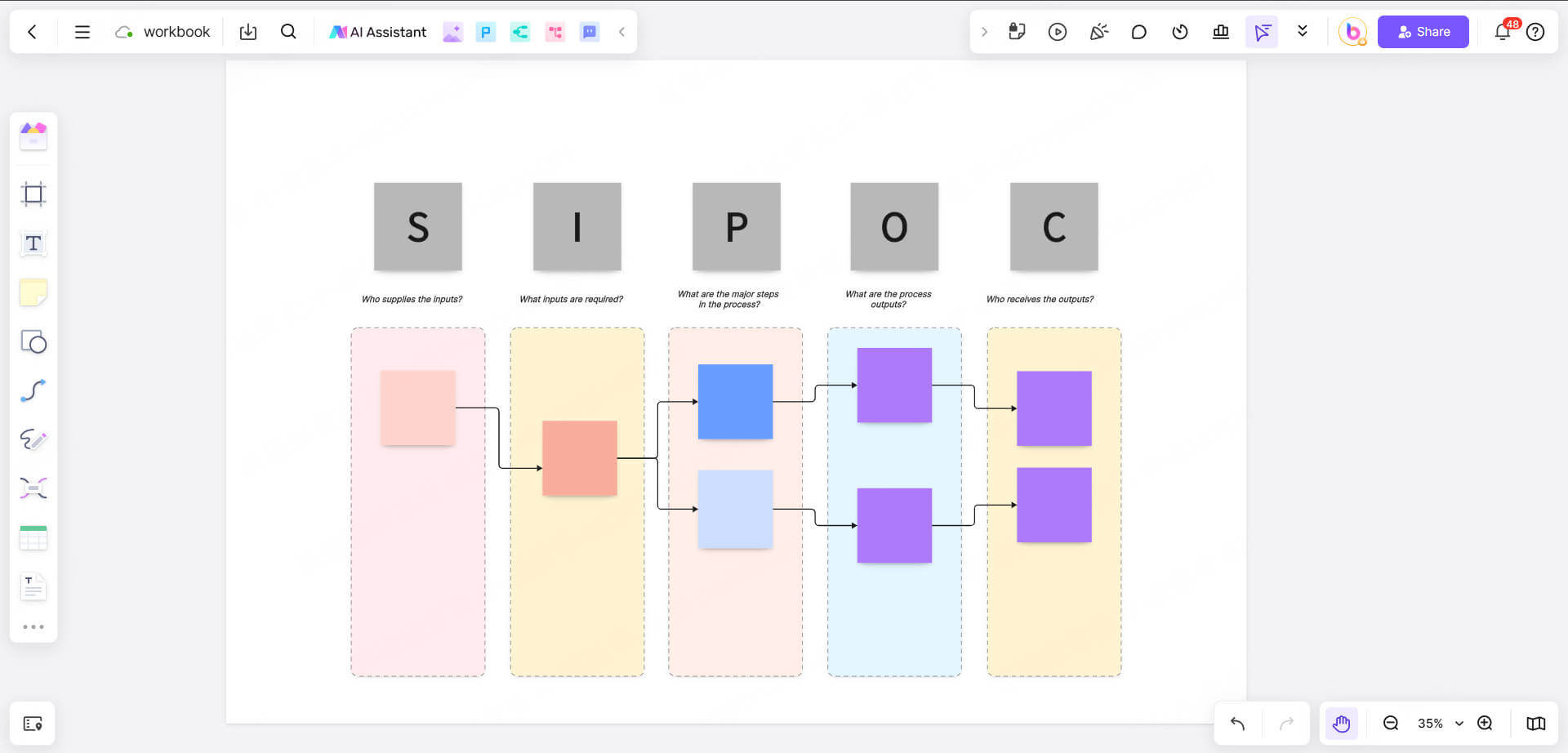

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) is a high-level process mapping tool, and Boardmix makes it incredibly easy with intuitive templates and drag-and-drop functionality.

Step 1: Select a SIPOC Template

Open Boardmix and choose the SIPOC template from the library. The template is already structured into five key sections: Supplier, Input, Process, Output, and Customer.

Step 2: Fill in the Details

Define each section based on your workflow:

- Supplier: Who provides the resources?

- Input: What materials or information are required?

- Process: What steps are involved?

- Output: What is the final product or result?

- Customer: Who receives the output?

Step 3: Customize & Enhance

Boardmix allows you to adjust elements, use color coding, and add annotations for better clarity.

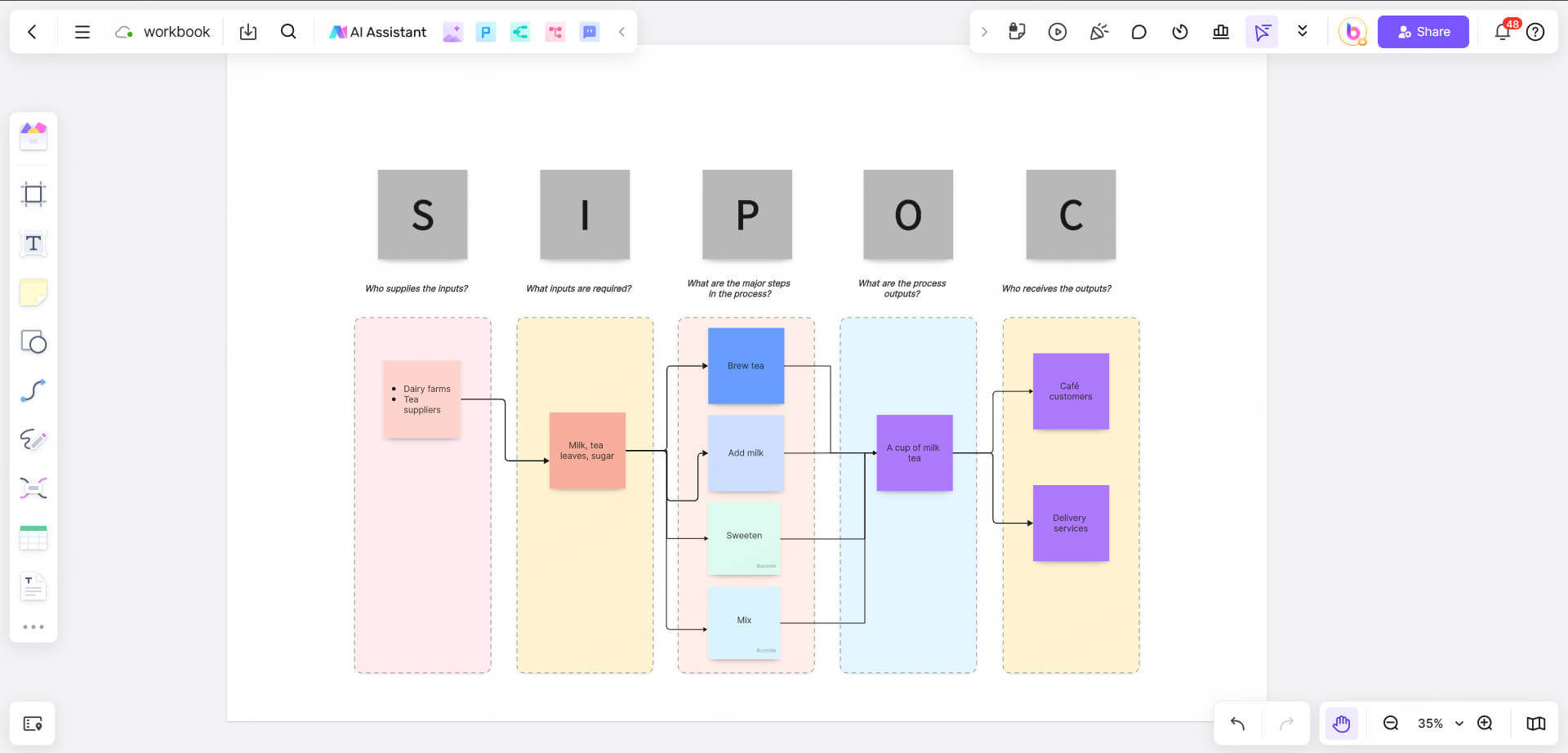

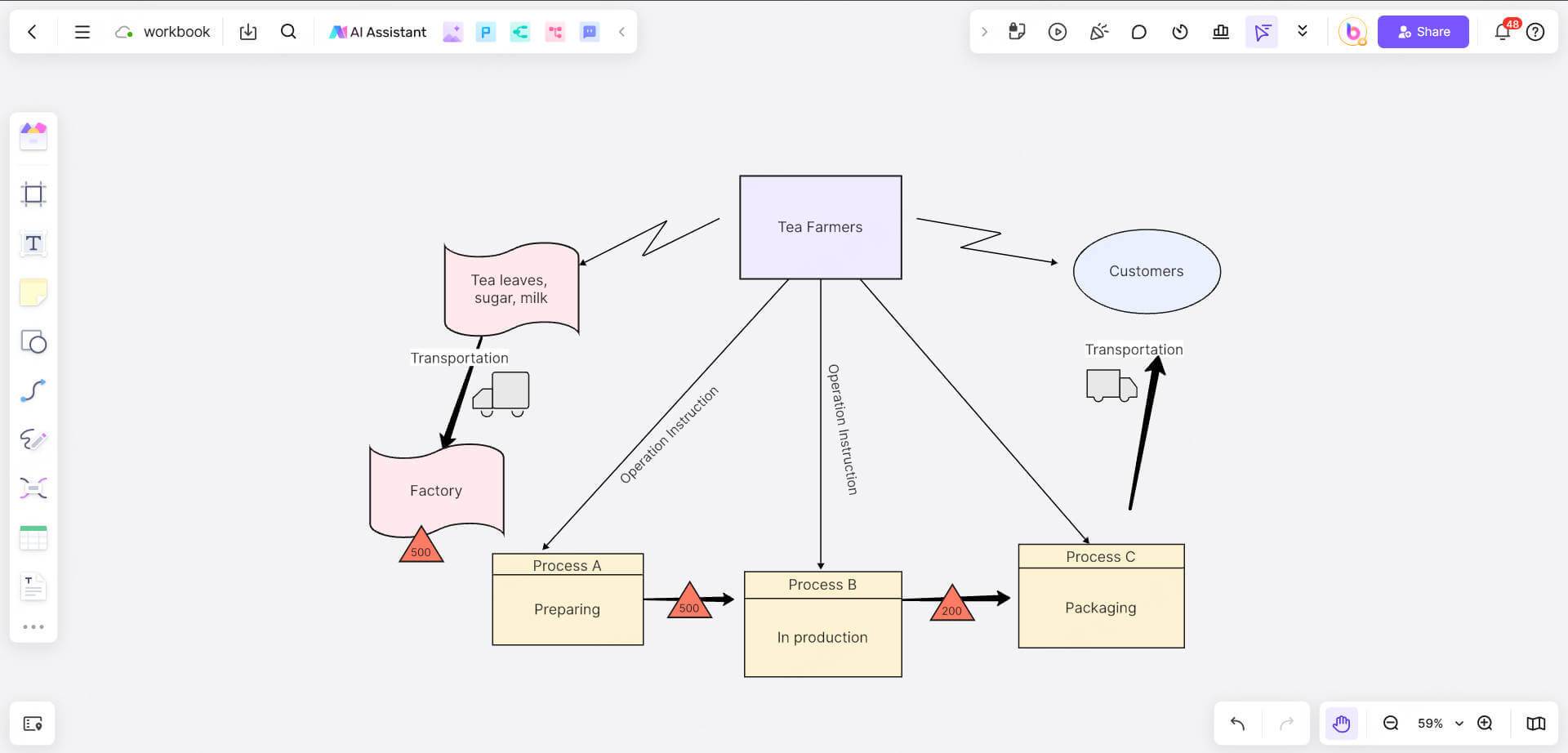

✨Example: Creating a SIPOC for Milk Tea Production

- Supplier: Dairy farms, tea suppliers

- Input: Milk, tea leaves, sugar

- Process: Brew tea → Add milk → Sweeten → Mix

- Output: A cup of milk tea

- Customer: Café customers, delivery services

With just a few minutes of setup, you get a structured and professional SIPOC diagram!

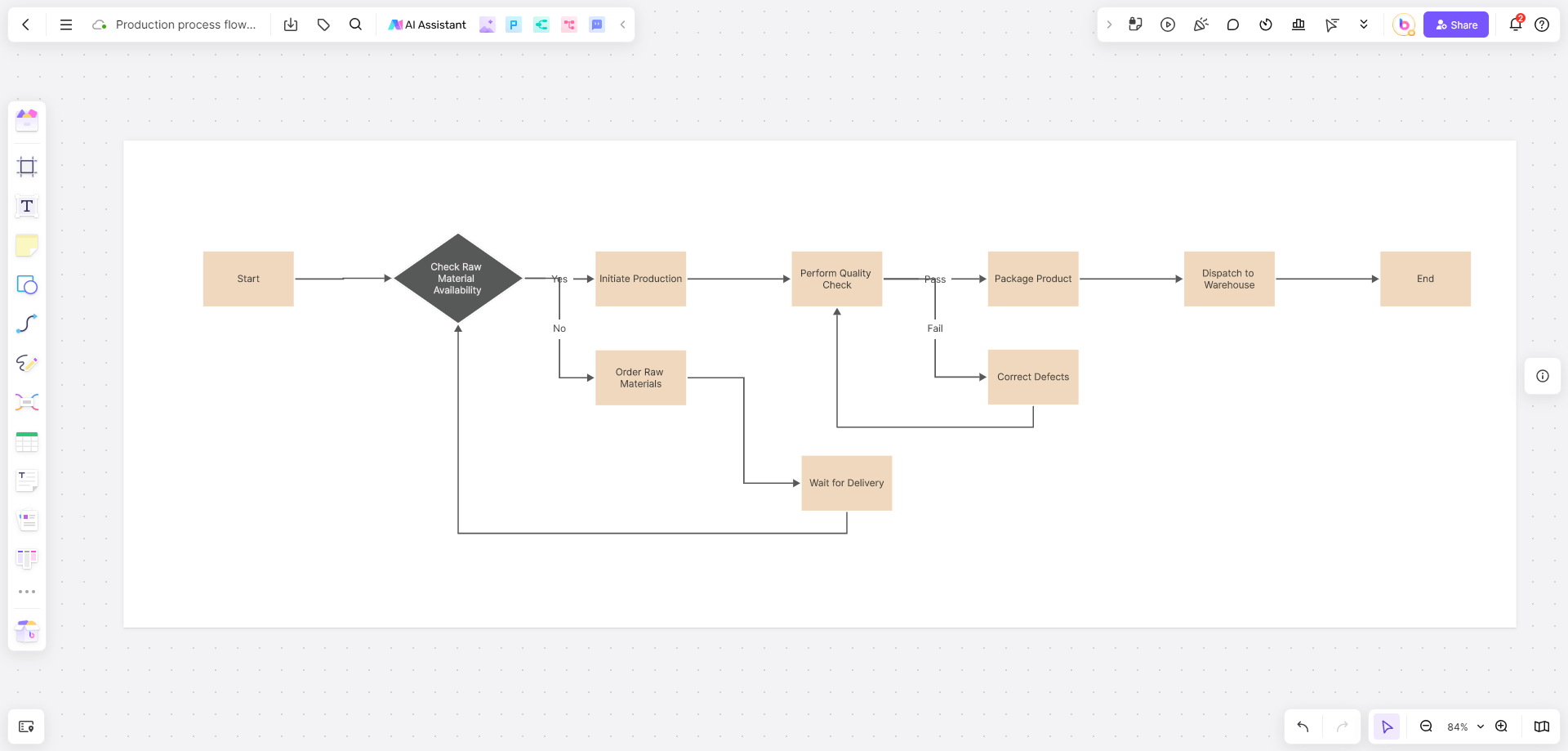

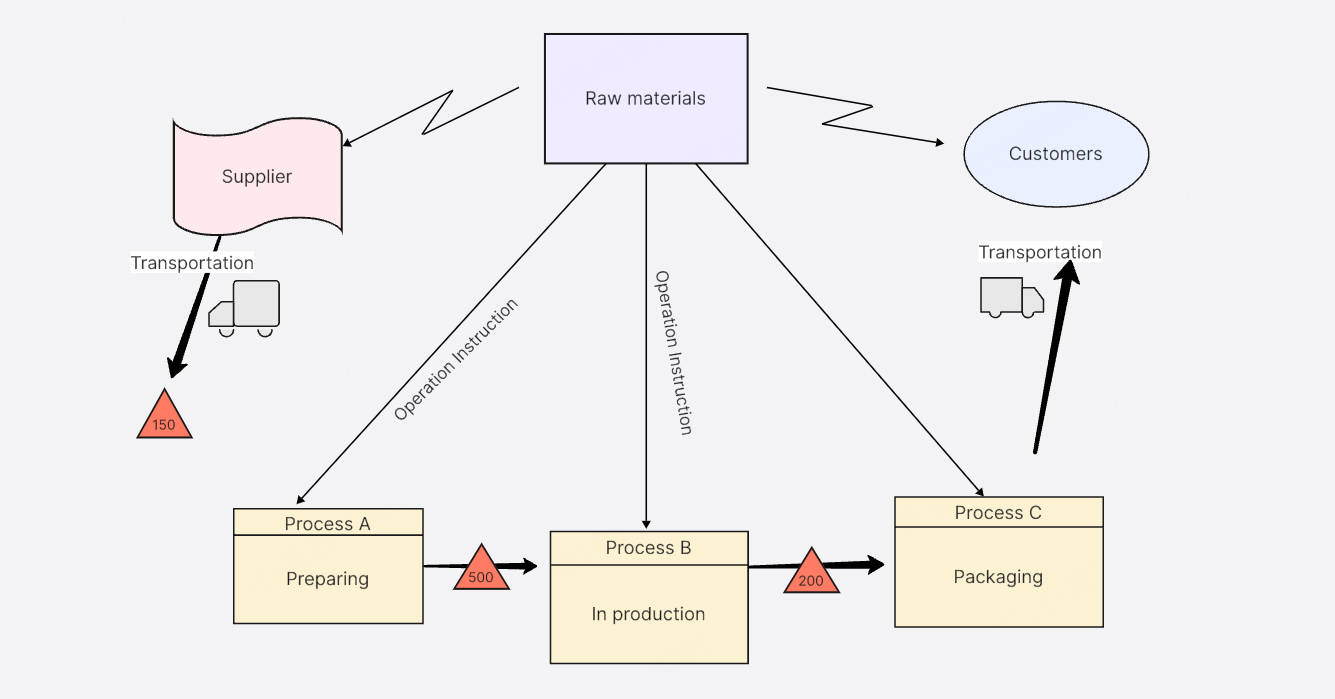

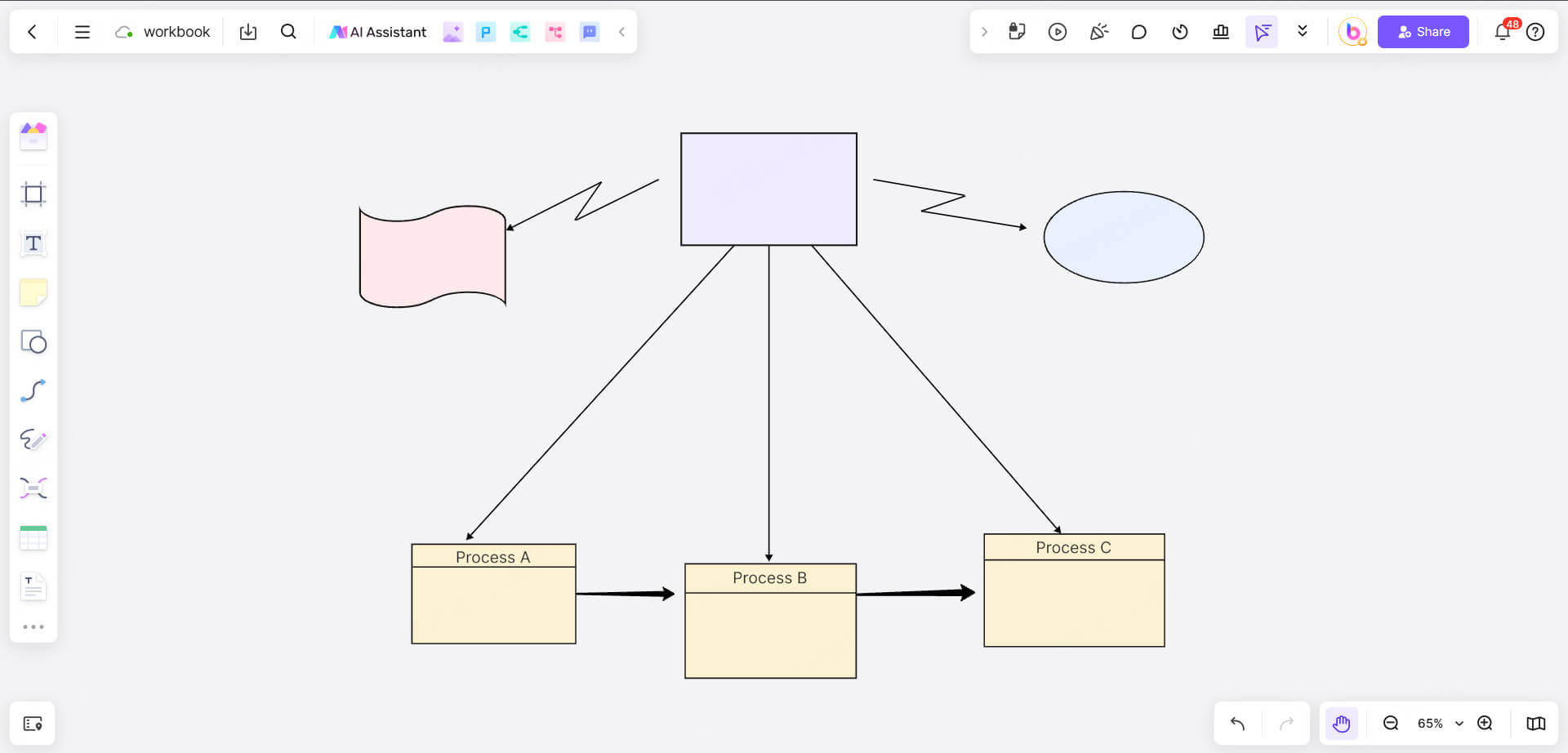

Creating a Value Stream Map with Boardmix

VSM provides detailed workflow analysis, and Boardmix’s advanced features make it even more efficient.

Step 1: Choose a Value Stream Map Template

Select the VSM template in Boardmix, which is pre-organized into key areas like material flow, information flow, and timeline.

Step 2: Draw the Current State Map

- Identify inputs, outputs, cycle times, and waste points.

- Use arrows to show the movement of materials and data.

- Apply color codes to highlight inefficiencies (e.g., red for waiting time, yellow for excess inventory).

Step 3: Design the Future State Map

Eliminate wasteful steps and combine repetitive tasks.

Optimize workflow to reduce time delays.

Use Boardmix’s annotation tools to document improvement strategies.

✨Example: Optimizing a Bicycle Manufacturing Process

Map current production bottlenecks (e.g., long inspection times).

Redesign with fewer inventory hold-ups and streamlined quality checks.

Use Boardmix’s color-coded annotations to make insights clear.

Whether you're mapping SIPOC or VSM, Boardmix enhances efficiency and clarity like no other tool. Its intuitive interface, rich templates, and powerful collaboration features make process optimization effortless.

Conclusion

Using SIPOC in the value stream map allows you to analyze processes, identify waste, and design optimization solutions more efficiently. Specifically, you can use SIPOC to clarify the process boundaries, and then apply SIPOC elements in VSM, such as using SIPOC to check waste and using SIPOC to verify the feasibility of future processes.

By combining these two tools, you can optimize processes more systematically, improve efficiency, and ensure that customer needs are always met. When you are having a headache with the complicated process, you might as well try this method.

Finally, if you're looking for a solution to streamline workflows and boost teamwork, try Boardmix for free, and it will definitely impress you!