What Is a PDCA Cycle

The PDCA (Plan-Do-Check-Act) cycle is a continuous improvement strategy that is used to enhance processes and execute changes. An effective method for identifying, evaluating, and resolving business issues. Team uses the PDCA cycle to carry out continuous iterative improvement and process.

It is essentially used when you want to develop a new business process, improve a repetitive work process, iterate on change, solve a problem, or test solution strategies.

The element of PDCA cycle are;

- Plan:To execute any change in your business or introduce a new process for product/service delivery, you must have a plan on how to get it done. Begin by setting up objectives, a team, and relevant stakeholders. Discuss those objectives and create a SMART goal for them. A good plan that can drive changes or new processes must answer some of these questions such as: What resources are required to carry out proposed changes or the new process? What are the potential hindrances in accomplishing those changes? What is the criterion for the success of the proposed changes? Remember plan has to be written down and presented as a working document. This is because other strategies in the PDCA cycle depend on it.

- DO:This is the part where you have to test-run those things stated in the plan. Implement each one on a small scale or in a controlled environment. This is to ensure that resources are properly utilized, even with minimal damage.

- Check:This is the analytical stage. Data obtained from Do-stage is evaluated. Assessment is done on the result to prove if it’s satisfactory or not. When a result is not satisfactory, then a further adjustment is needed on the overall goal, and everything falls back to the planning stage. But if the result is satisfactory, you can proceed to the Act stage.

- Act: This is the point where you fully implement the whole plan on your business. As time goes on, more study efforts should be applied to deliver more results and measure the outcomes accurately.

What Are the Pros and Cons of the PDCA cycle

Pros:

- PDCA cycle is versatile: It can be used in any type of business environment and management.

- PDCA cycle is easy to understand: It’s not complex, it can be taught in a simpler way.

- It minimizes waste and increases efficiency: Because it’s a strategy that involvestest-running innovations or new changes before they are fully implemented.

Cons:

- PDCA cycle is not the right approach to solving urgent problems: This isbecause its structure iterates implantation of processes and change.

- It requires cooperative commitment: It takes a team (not an individual) to practice the PDCA cycle. When commitment is not in the team, this cycle won’t work.

PDCA Cycle Examples

These are possible PDCA examples of popular companies that can still make them relevant in the market despite trends and competition. Thus:

PDCA Cycle Example - Nestlé

It is a multinational company based in Switzerland, known as one of the largest food companies globally. It produces a wide range of products such as dairy products, cereals, coffee, pet food, baby food, bottled water, etc.

PDCA cycle of Nestlé: There was a need to improve food safety and quality. So it launched “FARM TO FORK”, a quality management system to ensure access to high-quality raw materials from rural farmers. It was also a win-win strategy where it got high-quality material by enabling rural farmers and the farmers to get paid for their services.

PDCA Cycle Example - Nike

It is a big company known for producing all kinds of sports apparel. There is a notable example of a problem or situation that Nike solved using a strategy of PDCA:

In the 1990s, there was a problem of worsening working conditions in Nike contractor factories and violation of labor laws in Vietnam. The toxic solvents used in shoe production were causing health problems. Most workers were having nausea, dizziness, and respiratory disorders. The news went viral which spurred Nike to develop a continuous improvement strategy to execute changes.

Some of the practical solutions adopted were the introduction of a new code of conduct to protect workers, awareness of workers’ rights, and periodic training on safety practices. They implemented these solutions in Vietnam on a small scale despite Vietnam's stringent policies and it worked out well. So now, they have extended the same changes (solution) to all Nike factories globally. By 2001, 85 percent of Nike factories had conducted basic training on safety practices and factory operation. It has been a consistent practice till now.

PDCA Cycle Example - Lockheed Martin

It is a global company known for developing, designing, and manufacturing in the aerospace, defense, space, and cybersecurity industries.

It used PDCA to solve the long time taken to move products from the receiving department to the stock department. The strategies or plans they used were; using automated data collection system to eliminate inventory management errors, and introducing PEAQS program to drive supply management. After few years, consequently initial time taken to move products from receiving department to stock department reduced from 30 days to 4 hours. That was an excellent improvement in material management!

PDCA Cycle Examples - Mayo Clinic

It is a known hospital for best healthcare service delivery in the US. It adopted the PDCA cycle to improve the time taken to test patients. For instance in the plan, lean methodology was introduced to reduce heart-attack patients’ waiting time. This is achieved by structural adjustment to emergency protocols. After a few years of implementation, time was reduced from more than 7 hours to not less than 3 hours.

PDCA Cycle Example in Education

PDCA cycle helps teachers to be methodical in their lesson planning. It also helps to refine their teaching skills. An assessment was done on the efficiency of using the PDCA cycle to develop teaching proficiency in potential mathematics teachers in the US. After the whole process, teachers who were trained using the PDCA cycle performed better than other teachers, after carrying out a specific test.

How Do You Write a PDCA Cycle

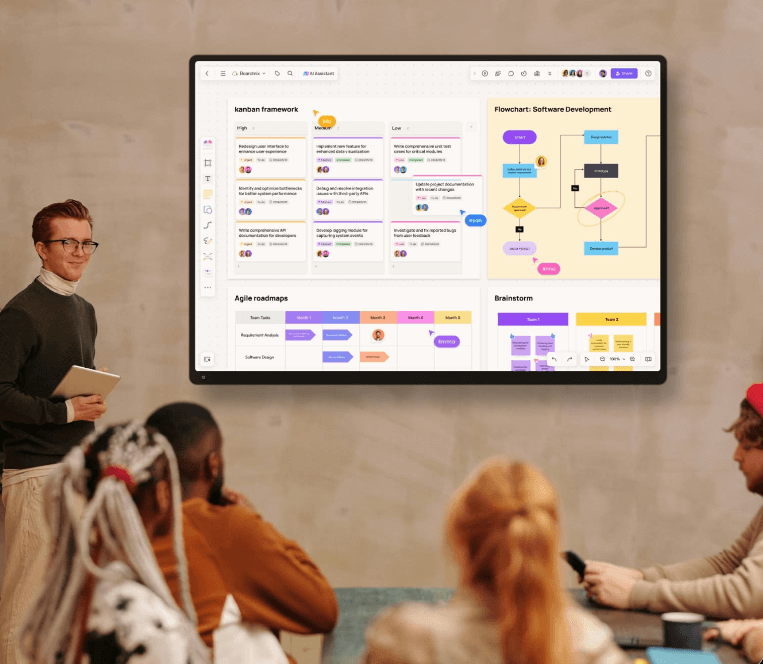

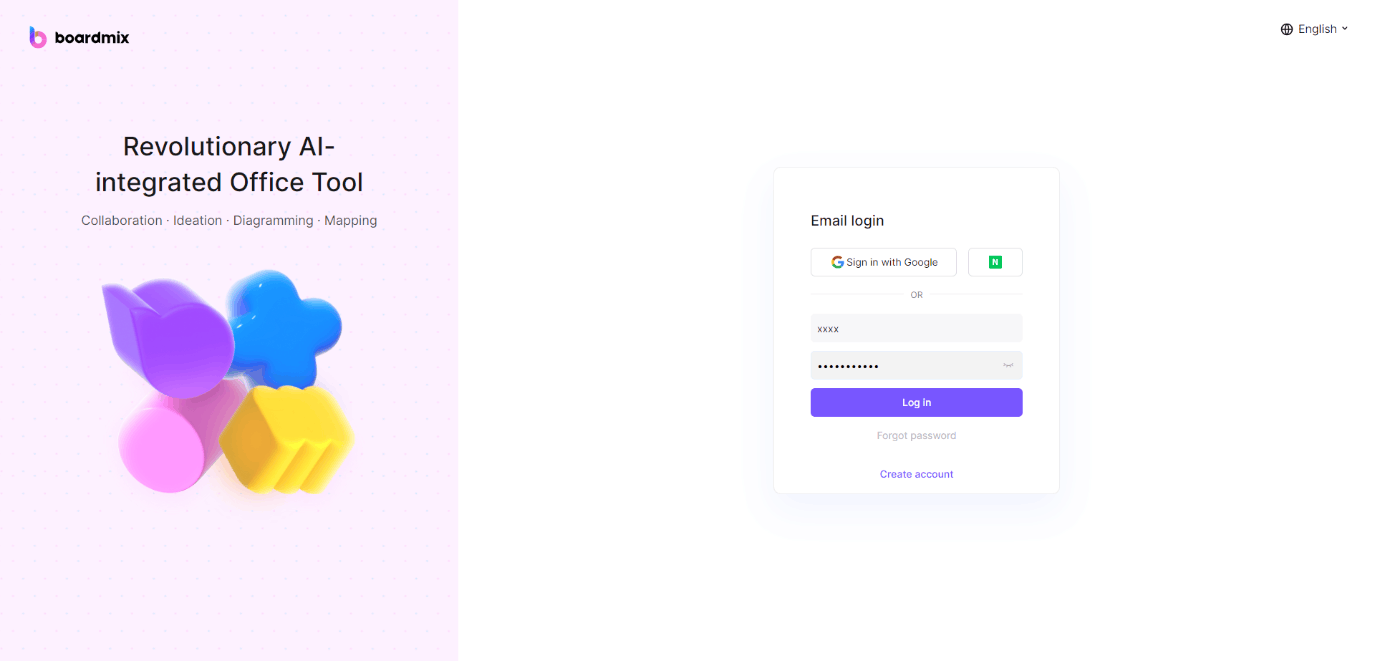

Want to improve any process in your business? Boardmix is worth a shot! Boardmix provides an online platform that serves you well on real-time collaboration and management. The preset PDCA cycle templates measures key performance indicators (KPIs) defined by you. Furthermore, it enables you to track the results of each attempt to promote continual progress. In other words, utilize the Boardmix PDCA template as a PDCA tool to help you through the various PDCA phases.

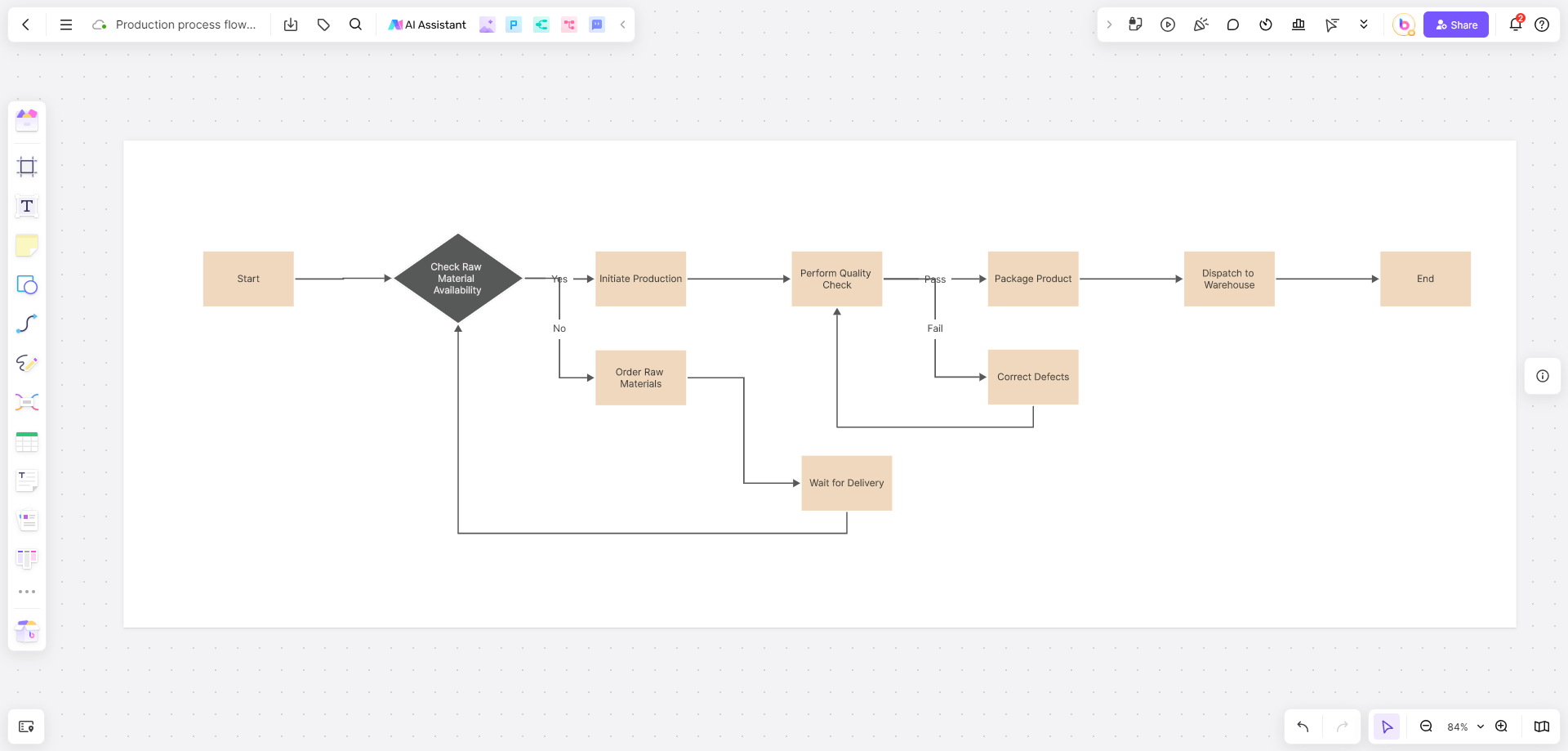

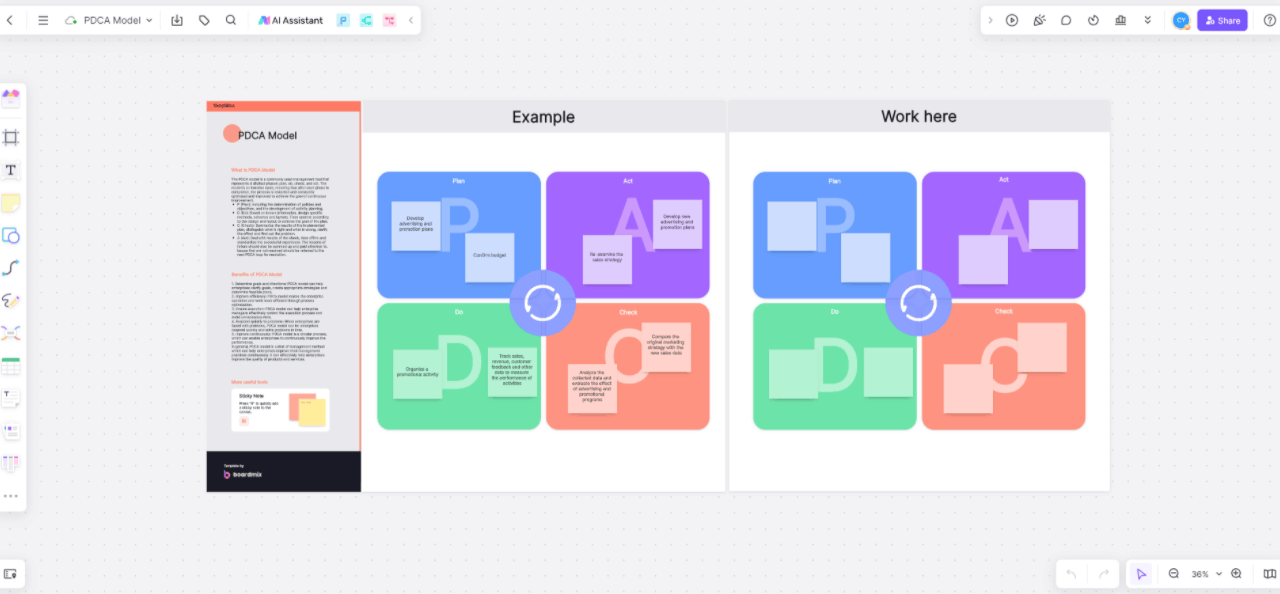

Here are the few steps you should take to create a PDCA model using the Boardmix PDCA cycle template:

- Log in or sign up with Boardmix.

- Click Templates and search for the PDCA model in the search box.

- Open the PDCA template and place it on the workspace by clicking the Use.

- The template structure is attractive and flexible. You can use edit tools, text tools, and shapes to create the desired layout. The template can be colored in any shade of color.

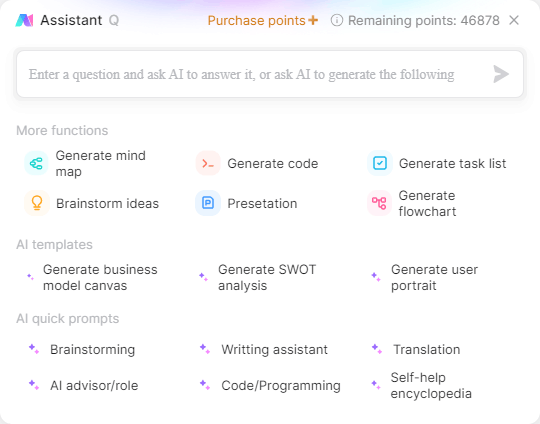

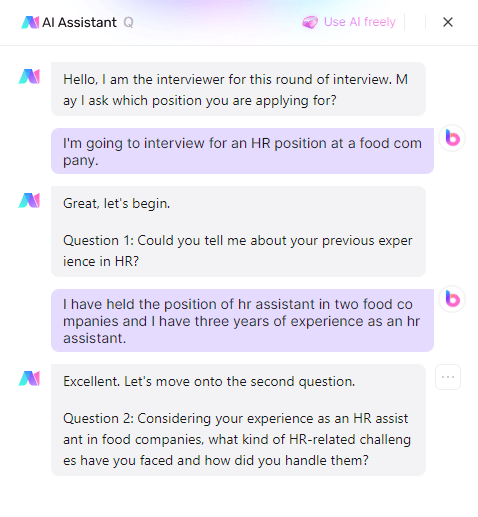

- If you need any help, the AI Assistant is always by your side.You can use it for data collection, data analysis and more.