A block flow diagram is a commonly used visual instrument to depict complex industrial chemical processes. This special type of diagramming technique was proposed in a book published in 2003 as a way to simplify the depiction of chemical processes.[ Peters, M. S. & Timmerhaus, K. D. (2003). Plant Design & Economics for Chemical Engineers, 4th Ed. McGraw-Hill.]

In the modern day, block flow diagrams have become the most simplified form of visual instruments in industrial literature. These diagrams allow operations management of a chemical processing plant breaks down complicated processes into easily understandable steps.

The aim of this article is to help professionals like you understand how block flow diagrams work, what they bring to the table as a tool, and how you can use a modern online whiteboarding tool to create block flow diagrams. Plus, we will give you a few example block flow diagrams at the end.

If you’ve been looking for this kind of guidance and assistance, keep on reading.

Part 1. Understanding Block Flow Diagrams

1.1 Introduction to BFDs

The first and the most obvious thing you have to do in your quest to build an impressive block flow diagram is to understand what these diagrams stand for.

With that, we mean you have to know more than the simple fact that block flow diagrams are drawn to visually represent chemical processes.

The best thing about learning to draw a block flow diagram is that they are quite simple, in terms of syntax. The shapes used for building BFDs are few with a handful of connectors.

In other words, learning how to create a block flow diagram is considerably simple and requires little time.

1.2 Overview of BFDs

Block flow diagrams are highly useful in managing plants and projects in the industry setting. These diagrams work as the initial step in establishing and developing effective chemical processes.

You can use various types of simple block flow diagrams to compare available options of chemical processes without spending any major sums of money and determine which might be best for you.

Once you know which processes may be right for your plant, you can then use BFDs to streamline these processes and shape your operations efficiently.

1.3 What is a Block Flow Diagram Used for?

BFDs are often understood to have a very specific purpose: to visually represent a chemical process. However, this particular application is not something this diagramming technique was invented for, even though this is its claim to fame. That’s what people know it for.

In addition to helping identify and hone processes for industrial plants, block flow diagrams can be excellent planning and organizational tools for process reports and industrial literature like textbooks, whitepapers, and process presentations.

What makes block flow diagrams so useful today is the fact that a layman with a preliminary knowledge of industrial jargon can easily understand the information they depict.

In fact, even somebody with no experience in industrial processes would be able to follow the steps of the chemical process a BFD demonstrates.

Part 2. How to Create a Block Flow Diagram with Ease

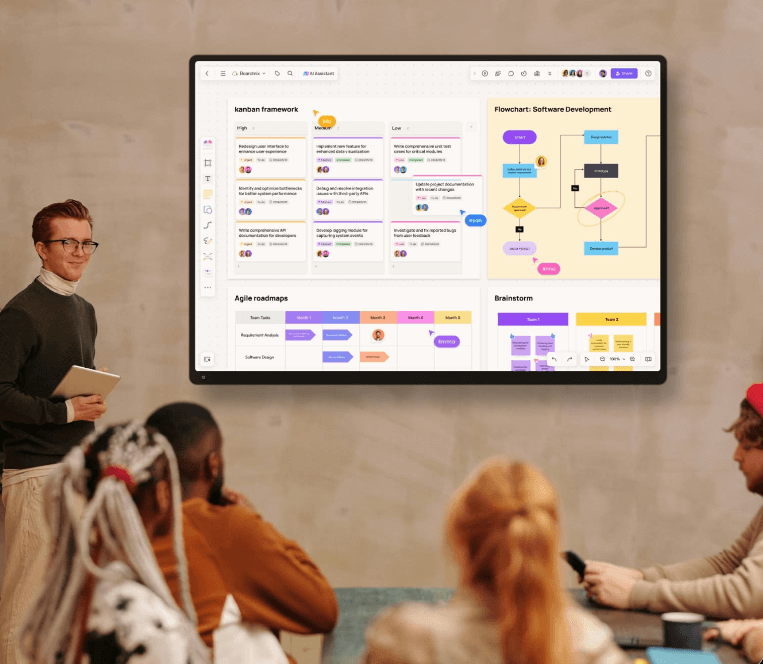

Creating a block flow diagram is quite easy, especially with a tool like Boardmix.

Boardmix is an online technical drawing tool that allows project managers and their teams to work collaboratively, building various types of diagrams and visuals together in real-time. The platform offers a variety of shapes and drawing tools that can help you build simple to complex block flow diagrams in little time.

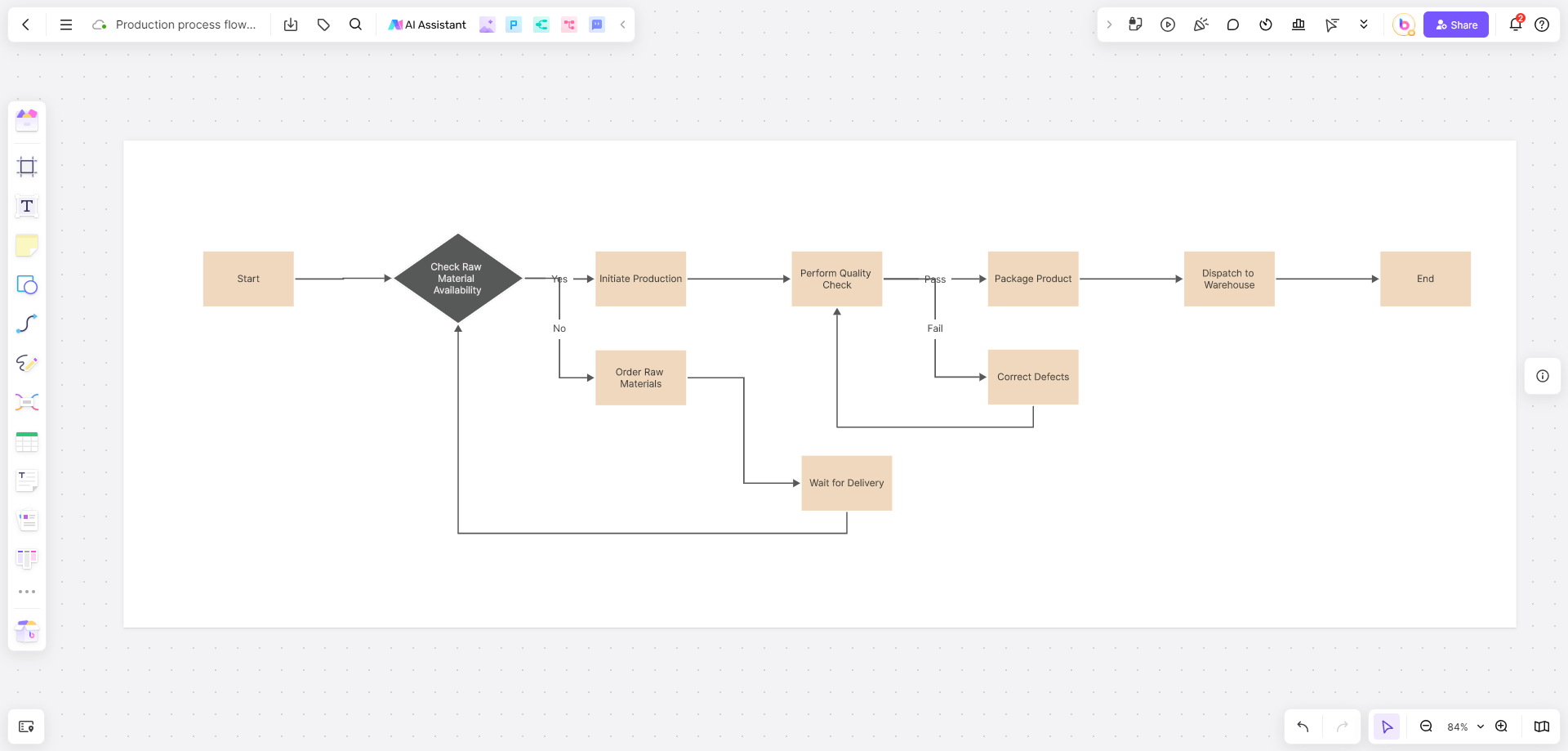

Here are the simple steps you will need to draw a simple BFD in Boardmix:

Step 1. Sign in to your free Boardmix account using your email and chosen password. Once you are logged in, click on the blue “Go to Workspace” button in the top right corner, as shown below.

Step 2. Choose your scene and start a “New Whiteboard”.

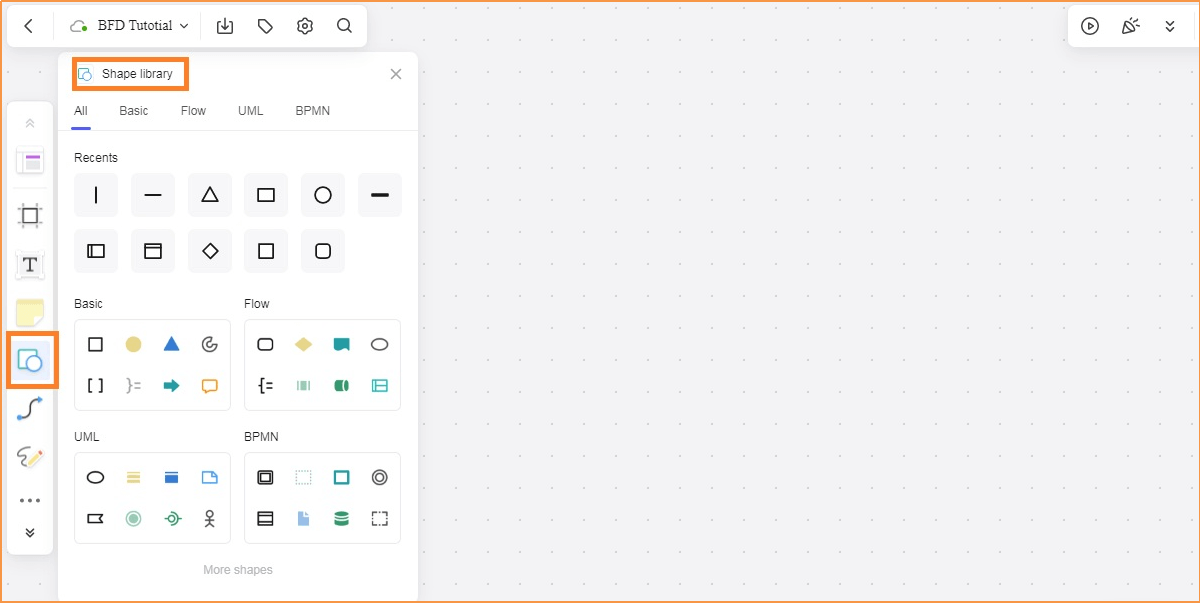

Step 3. Click on the Shapes icon in the vertical toolbar you will always see the left side of your whiteboard. This will open the Shapes Library.

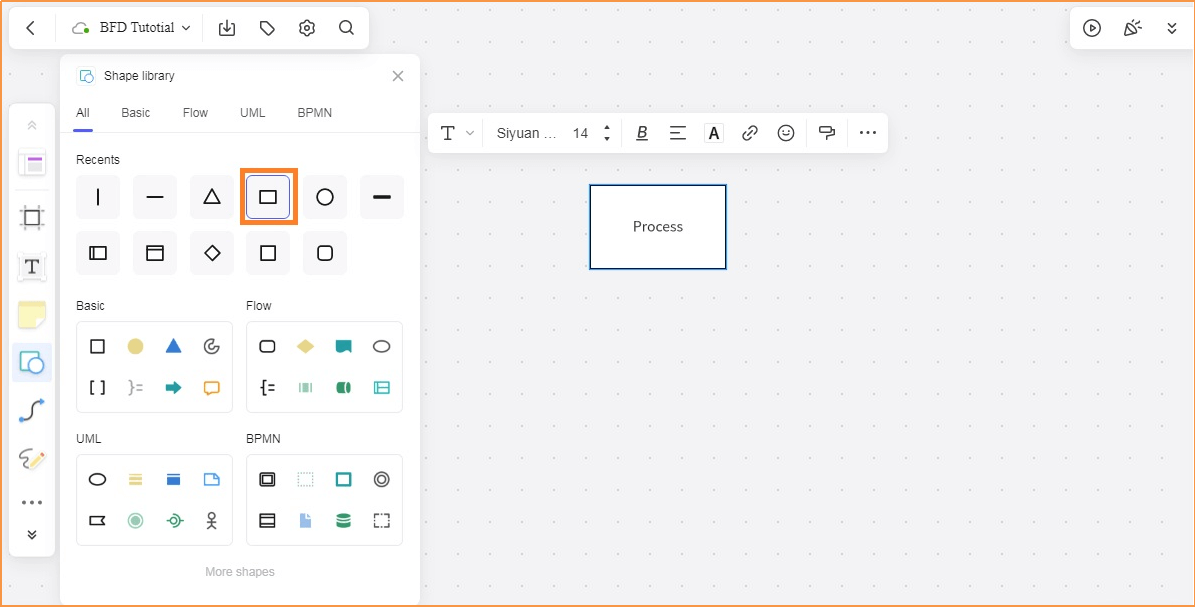

Step 4. Simply click on the shape you want to use and then double-click on the spot where you want it to appear on your whiteboard. The shape will appear with a toolbar filled with customization features for the shape and the text within.

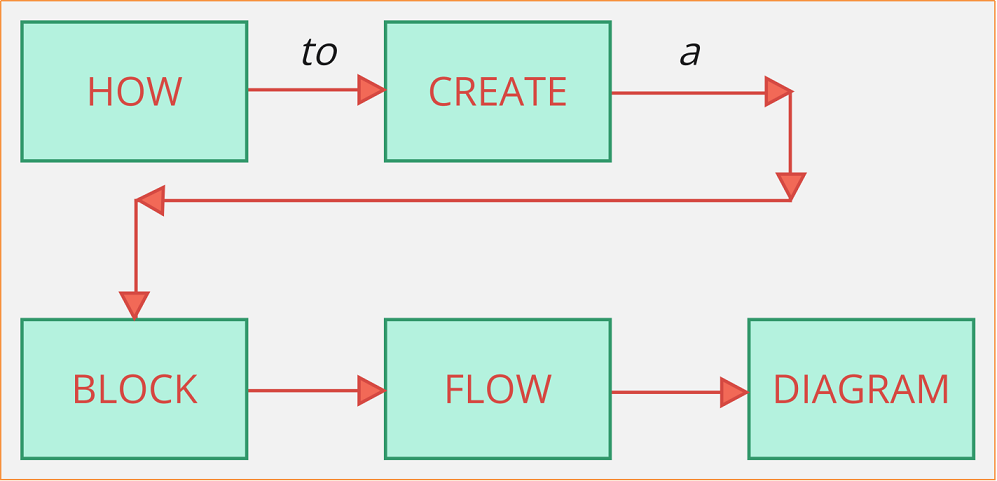

Step 5. Add more shapes and connect them using lines and arrow connectors. Your block flow diagram will be ready in no time.

Part 3. FAQs about Block Flow Diagrams

1. What are the top 3 benefits of using a block flow diagram?

While a long list can be made out of the benefits block flow diagrams have, here are the top 3:

- BFDs allow plant owners and managers to study and choose the most suitable alternatives for chemical processing without investing large sums of money or a lot of time. Practically building plant setups to run processes and choose the most suitable methods would require a lot of money and time, but block flow diagrams cut through this need and provide useful insights into making this decision without such investment.

- A block flow diagram makes it much easier to communicate the various steps within a chemical process to various kinds of audiences. With a BFD, you can present a new process to plant management and other stakeholders through various media.

- A block flow diagram helps plan and implement complex chemical processes efficiently. With a BFD at hand, you can easily break down the various steps you need to take to set up your new plant and run the chemical process.

2. What are the key rules of creating a block flow diagram?

There are straightforward rules when it comes to creating a block flow diagram. Of course, you have to first understand the shapes and other syntaxes involved in building one.

So, for example, when drawing a BFD we break down the process into equipment-based steps and call each one of them a unit.

These units are represented as rectangles and circles in a block flow diagram.

These units are put on the paper in their order of occurrence during the chemical process. Then we use lines with a single arrowhead each to connect these units. These lines and arrows show the flow of materials throughout the process from one unit to the next until the process is completed.

As such, you can draw a block flow diagram to depict a complete chemical process with all its streams of materials. Materials used in every stream are identified using labels put over or adjacent to the stream.

3. What are the key differences between block diagrams and flow diagrams?

Block diagrams and flow diagrams may have a lot in common in appearance, but the two are actually quite different in their purpose, diagramming technique, and applications.

A key difference between the two lies within their very definitions. While a block diagram delineates an industrial process, laying out its various steps and how materials are processed, a flow diagram shows how information in a given system is managed and travels across the system.

Another significant difference between the two is the fact that you need to label each block within a block diagram to demonstrate what it represents in a block diagram. But flow diagrams often have specific items and shapes that have an existing identity and purpose.

Conclusion

To sum up, this article talked at length about what BFDs are and why they are used. We learned that block flow diagrams have a lot of significance in industrial process design since they allow plant managers to create viable process plans without investing a lot of time or money.

Additionally, we answered some frequently asked questions to staple the fundamental information you received about BFDs in the earlier sections of the article. This information helped you build a deeper perspective on how a block flow diagram is constructed, what its benefits can be, and how it differs from a conventional flow diagram.

Besides, if you are looking for a tool to help you easily create block flow diagrams, try Boardmix for free!