Every company has different sets of processes that are designed to carry out day-to-day operations and deliver products/services to customers. Every single process involves multiple interlinked activities, so there are always chances of the presence of time-wasting or defective activities that might compromise the process quality. Therefore, it is important to analyze processes regularly to optimize them in terms of time and resources. The first step at this stage is mapping the processes to visualize all the steps and activities they go through. This process mapping is termed as "Lean Process Mapping", which is the map that helps visualize and improve processes in terms of time, cost, efficiency, and other aspects. So, let's closely look at what lean process mapping is all about and the best tool to create it.

Part 1. Everything You Need to Know About Lean Process Mapping

Process mapping is just like process modeling that provides a comprehensive diagram of all the steps, roles, and resources involved in a process. The process map can vary from business to business, as there can be maps that just highlight steps, while there can be other maps that provide a complete look at timelines, roles, resources, steps, etc. Lean process mapping is one main type of process mapping that intends to reduce waste in the process.

1.1 What is Lean Process Mapping

The word "lean" refers to a philosophy that emphasizes eliminating non-value-add or waste activities to streamline operations through continuous improvement. In terms of business, lean emphasizes eliminating all such activities that don't add value to the creation/improvement of products and services for customers. So, lean process mapping is about creating a process map with the top priority of reducing waste.

The lean process mapping focuses on time, i.e., the time utilized between activities. In addition, lean process mapping can also emphasize reducing timelines, enhancing quality, maximizing customer value, and similar other objectives.

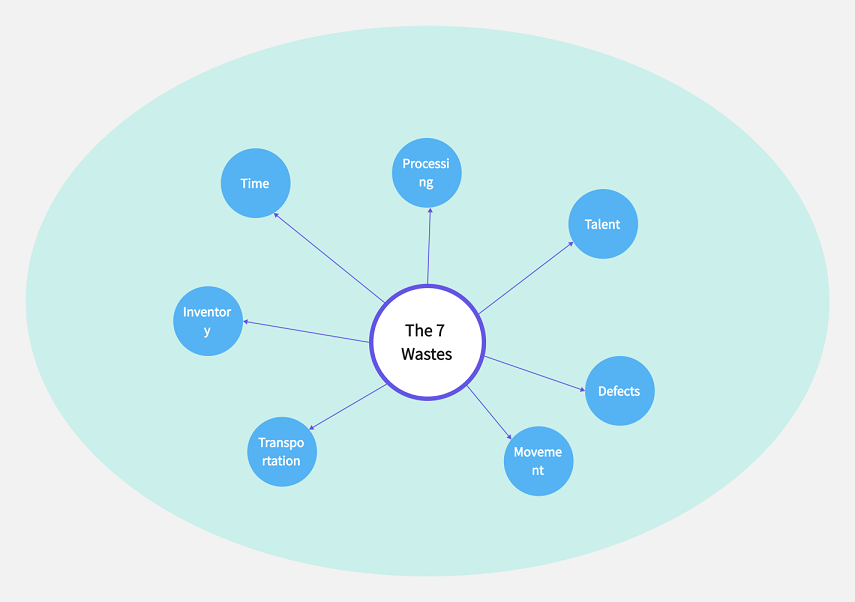

1.2 7 Types of Wastes Lean Process Mapping can Eliminate

The core purpose of creating a lean process map is to eliminate waste, whether it's in terms of time, cost, quality, or any other. In most cases, the lean process mapping is used to eliminate below 7 types of waste:

- Time: Detect time spend on certain activities, as lengthy processes mean more cost and resources.

- Talent: Look into the utilized talent to pinpoint "wasted talent", which implies the talent that is not used efficiently or causes poor outcomes.

- Movement: Detect unneeded or frequent movements in the warehouse or other places that can increase time and cost.

- Transportation: Detect transportation-related wastes, such as long delivery routes, unneeded movement of people, moving/updating information in different systems, etc.

- Inventory: Look for overproduction, inventory duration in the warehouse, stacks of papers, raw materials, and all similar inventory-related wastes.

- Processing: Detect stages in a process where overprocessing is happening, such as duplicate work, overproduction, non-value work, overwork, etc.

- Defects: Pinpoint defects that can bring waste in the form of rebuilds, returns, bugs, etc.

All these kinds of wastes are mapped via lean process mapping. In short, a lean process map effectively improves processes and significantly saves time and resources.

Part 2. The Best Tool for Lean Process Mapping

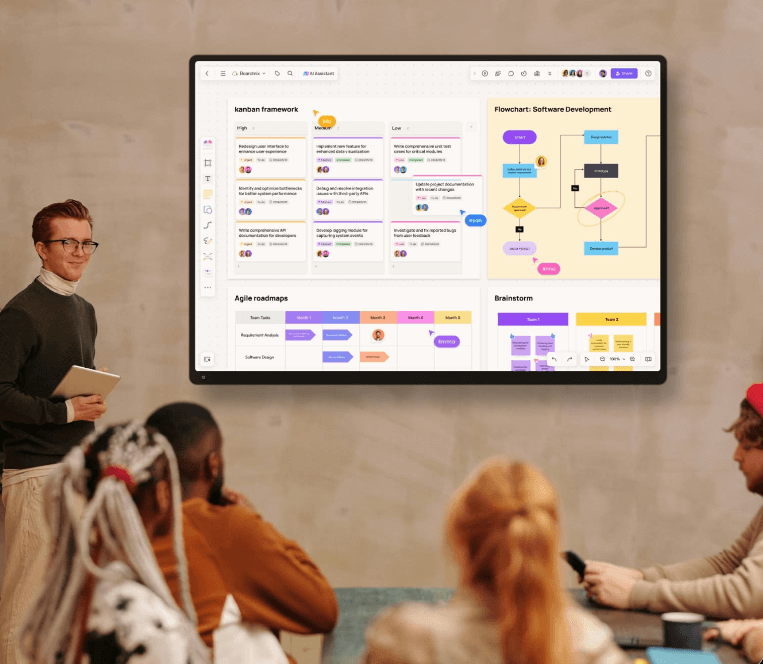

Lean process mapping is all about producing more in less time. Moreover, it is an excellent way to improve quality and increase customer satisfaction. Since a lean process map holds tremendous value for businesses, it must be designed easily, instantly, and collaboratively. This is exactly where Boardmix comes into action.

Boardmix is an online collaborative whiteboard that provides all the toolkits and functionalities that businesses need to create simple to detailed lean process maps easily. Its feature-rich and user-friendly interface provides access to all main tools, such as pen, note, shape, connection line, eraser, frame, and similar others. Moreover, it allows multiple team members to collaborate on a single file in real-time.

Key Features of Boardmix

- It provides many built-in templates to create lean process maps instantly.

- It keeps track of changes with auto-saved version history.

- It supports simple drag-and-drop of shapes, arrows, and other elements to create detailed process maps easily.

- It allows real-time collaboration between participants on the same file.

- It is free to use for individuals and small teams with access to unlimited projects and participants.

- It can export lean process maps as .png, .svg, .pdf, .jpg, and .bdx file formats.

Overall, Boardmix serves as an all-in-one online tool to create, collaborate, and share detailed lean process mapping instantly.

Part 3. Lean Process Mapping Examples

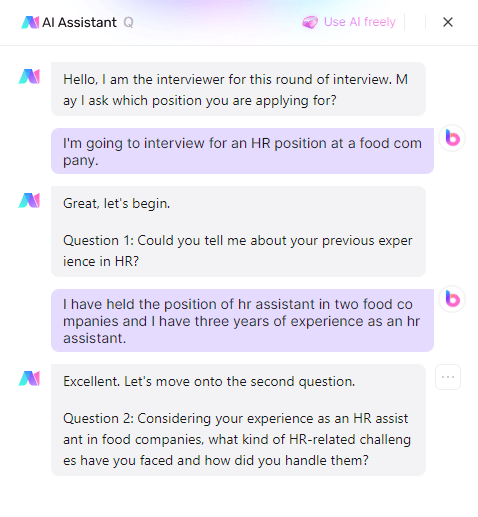

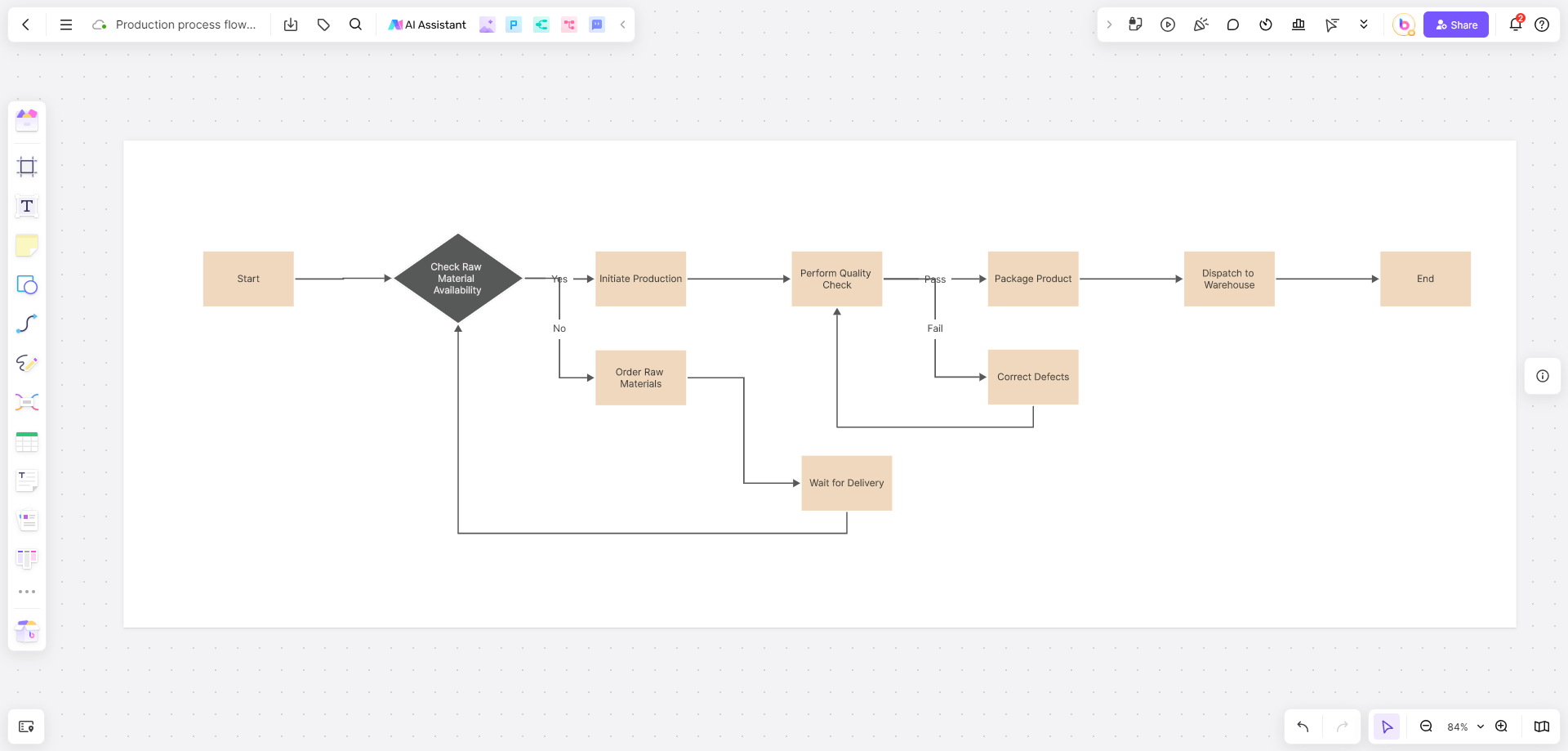

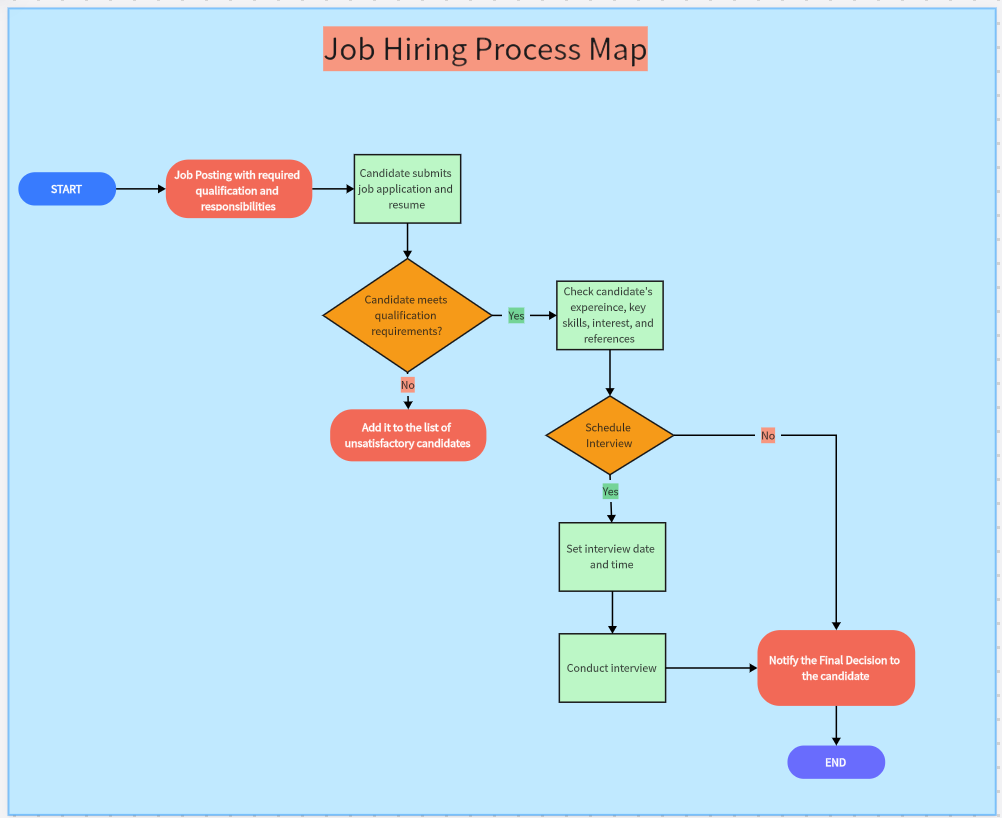

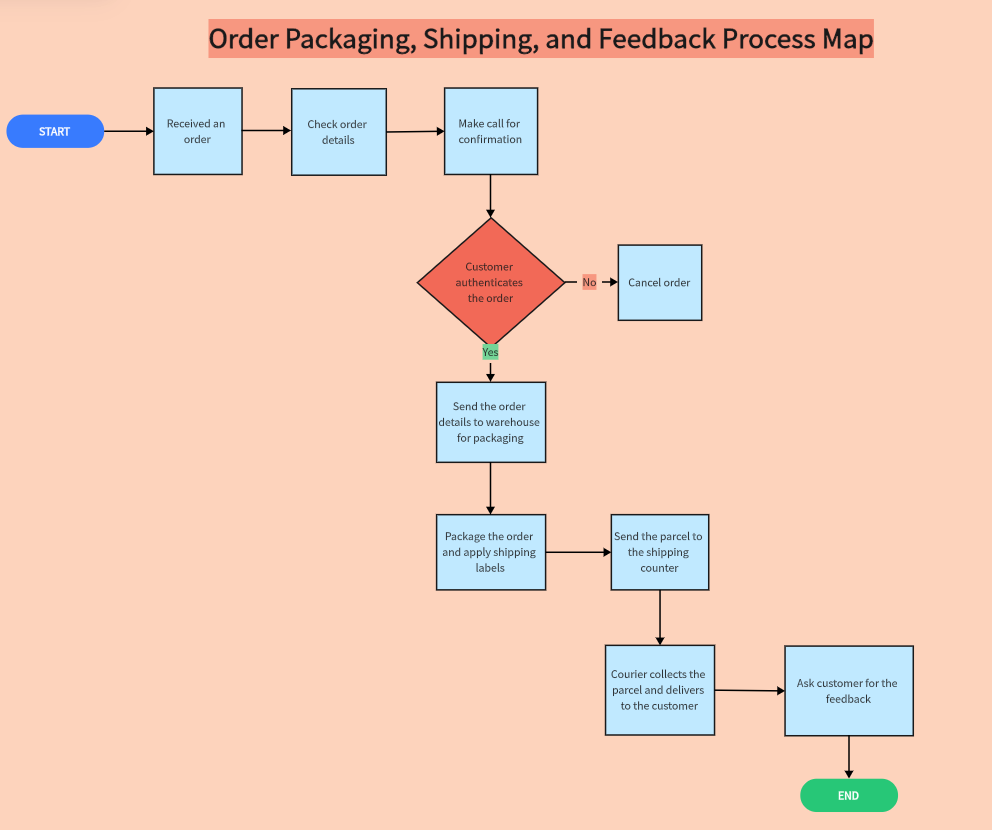

Now that we know what lean process mapping is and the best tool to create such maps, let's discuss a few examples. So, below are the two examples of lean process mapping created via Boardmix:

1. Job Hiring Process Map

2. Order Packaging, Shipping, and Feedback Process Map

Conclusion

There is no such thing as a complete and efficient process free from defects or waste. There are always some improvement aspects hidden in a process that must be exploited. Lean process mapping is a perfect way to visualize a process and pinpoint its waste elements. If you are also looking to optimize your business processes, then you can start designing lean process maps right away with the powerful Boardmix online tool. Its intuitive user interface, built-in templates, real-time collaboration, and similar feature-rich aspects make it the ideal tool for lean process mapping.