Entrepreneurs need to adopt a proactive approach when evaluating the success or flop of a design or process. While there are many ways to explore, one effective method is the Failure Mode and Effects Analysis. The FMEA template can help you understand your business in-depth and plan corrective techniques to lessen the incidence of failures.

What is FMEA Template?

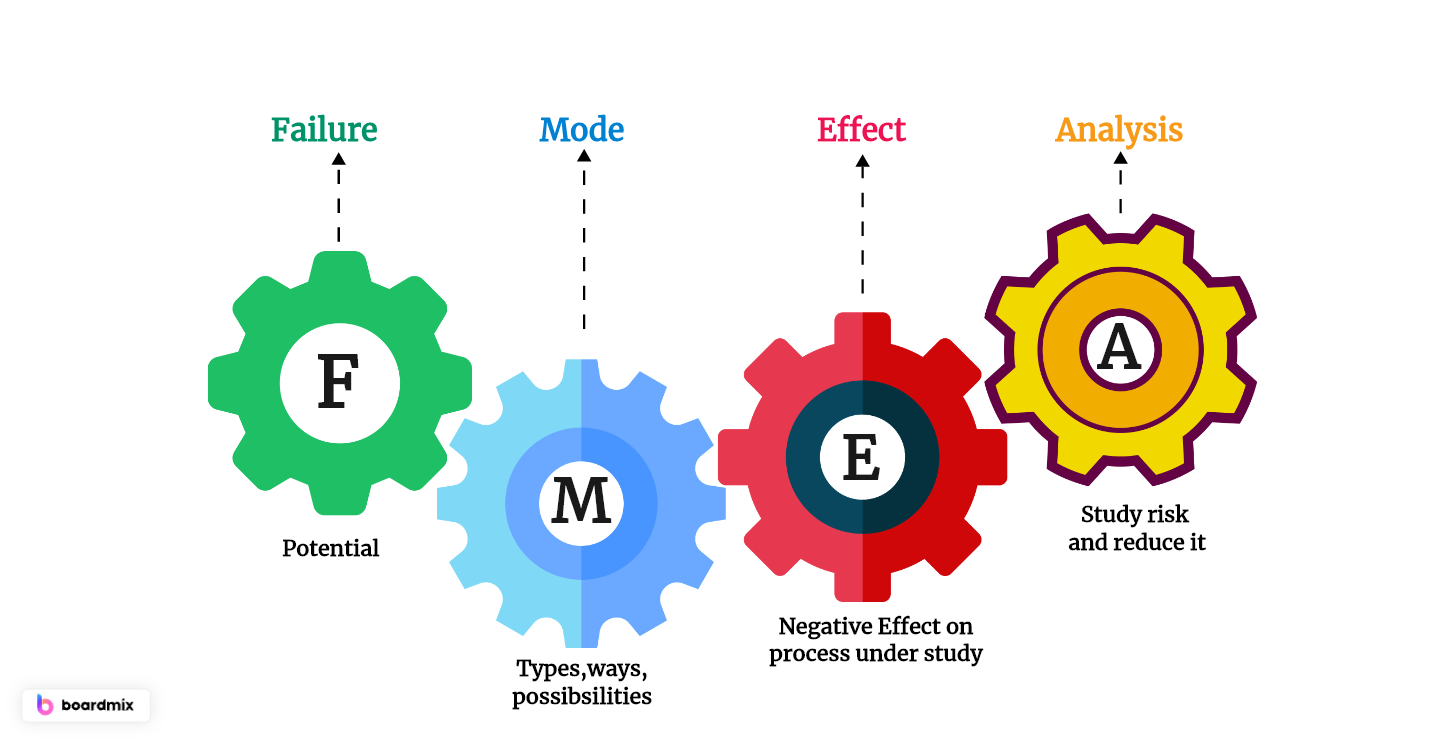

The FMEA analysis is a systematic tool that can foresee possible failures in a product or process. The US Military devised it in the 1940s to structure solutions to potential errors. Today, this qualitative tool can prevent bleeding losses by finding the cause and effect of probable failures.

The concept of Failure Mode and Effects Analysis inspects a design or process and determines two aspects:

- Failure Mode(s). The modes or situations that may cause any error or defect to happen. This portion of the report distinguishes pain points in the early development or production stage. It specifies possible failures that may affect the customer, which could hamper the business's success.

- Effects Analysis. This part refers to identifying and evaluating probable consequences of every forecasted failure.

Failures are prioritized based on the severity of the consequences, and actions start from the most serious problem. FMEA allows teams to take action to reduce or eliminate the possibility of failure. It’s important to remember that this process does not stop after identifying issues. It is also used for control purposes throughout the product’s lifespan.

Application of FMEA Templates

Automotive Industry: Car Manufacturing

Application: In the automotive industry, FMEA is extensively used during the design and manufacturing processes of vehicles. For example, when developing a new car model, engineers conduct an FMEA on the braking system.

Process:

-Identify Potential Failure Modes: Brake pad wear, brake fluid leakage, ABS sensor malfunction.

-Assess Effects and Severity: Reduced braking efficiency, increased stopping distance, loss of vehicle control.

-Analyze Causes: Material fatigue, improper installation, sensor failure.

-Determine Controls: Regular maintenance schedules, quality control checks, and sensor diagnostics.

-Implement Actions: Enhance material quality, improve assembly procedures, and install more reliable sensors.

Healthcare Industry: Hospital Surgery Department

Application: In healthcare, FMEA is used to improve patient safety by analyzing potential failures in surgical procedures.

Process:

-Identify Potential Failure Modes: Incorrect dosage of anesthesia, surgical site infection, equipment malfunction.

-Assess Effects and Severity: Patient overdose, post-operative infections, procedure delays, or complications.

-Analyze Causes: Human error, non-sterile conditions, lack of equipment maintenance.

-Determine Controls: Double-check medication doses, sterilization protocols, and regular equipment inspections.

-Implement Actions: Training programs for staff, stricter sterilization procedures, and scheduled maintenance routines.

Consumer Goods Industry: Household Appliance Production

Application: FMEA is applied in the development of household appliances, such as washing machines, to identify and mitigate potential failure modes.

Process:

-Identify Potential Failure Modes: Motor failure, water leakage, control panel malfunction.

-Assess Effects and Severity: Appliance breakdown, water damage to home, user frustration.

-Analyze Causes: Motor overheating, faulty seals, electronic component failure.

-Determine Controls: Design improvements, enhanced sealing techniques, robust component testing.

-Implement Actions: Use higher-grade materials for motors, improve seal designs, and implement comprehensive testing protocols.

How to use the FMEA template?

The Boardmix's FMEA template is available under the ‘Templates’ tab of the platform. Simply select the specified template and fill in the corresponding details. The good news is that this tool is easy for all team members to use, edit, and track!

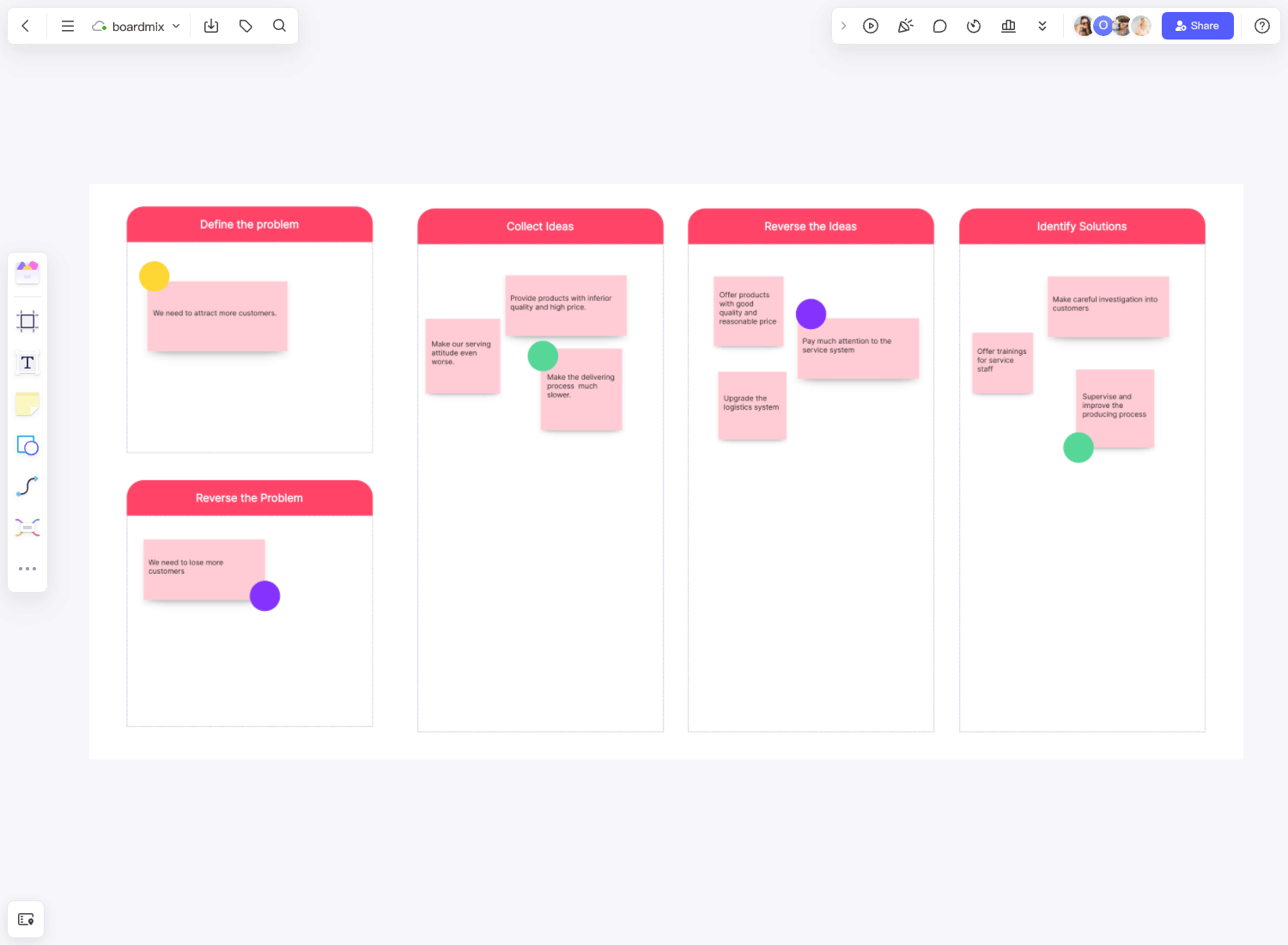

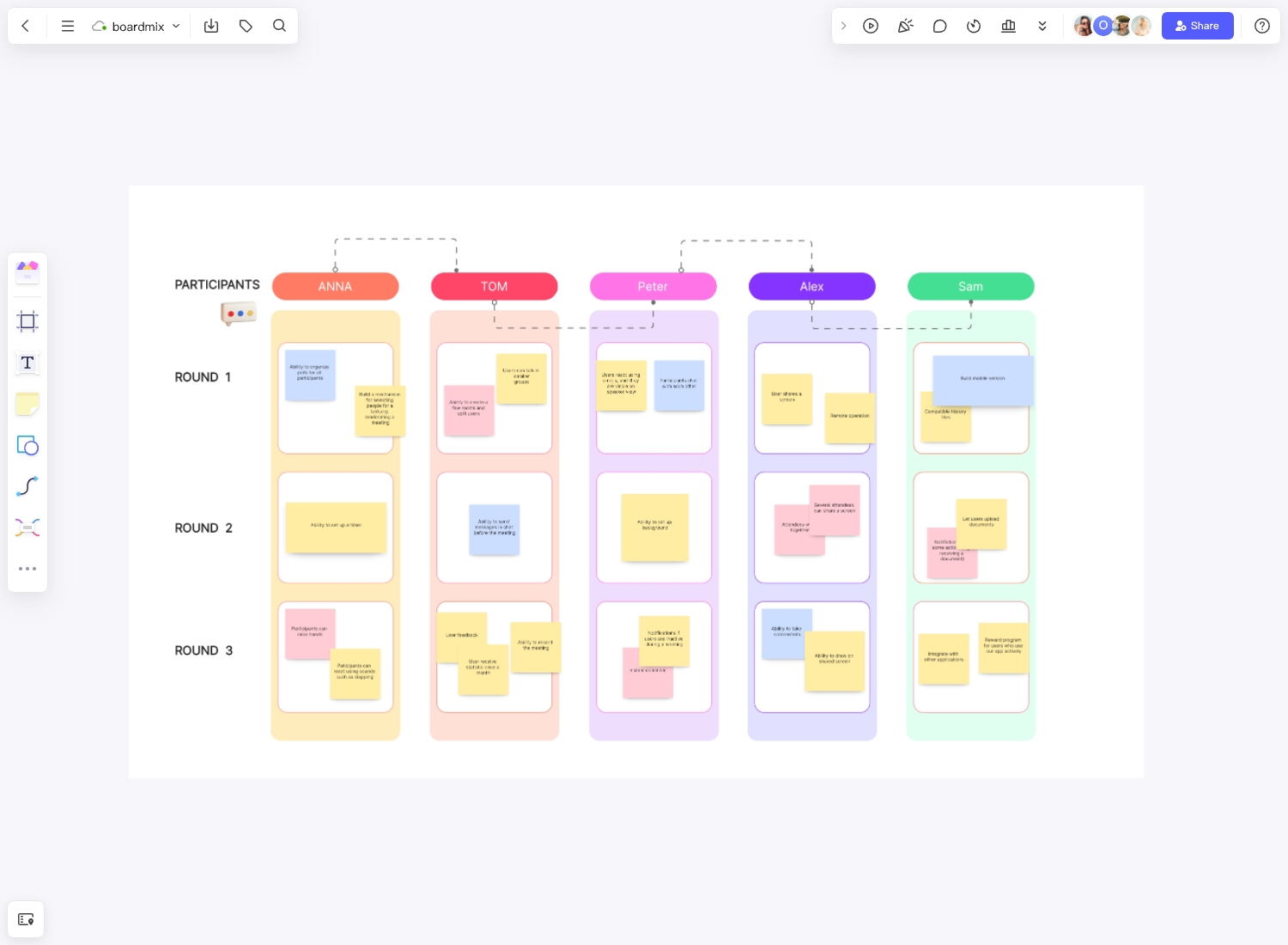

There are many ways to tackle and implement FMEA, and you can customize the template to fit your company. That said, creating a team that can provide valuable input on the brainstorming process is crucial. Doing so allows you to cover all your bases and identify potential failures in every aspect of your business.

When to use FMEA Template?

You can utilize the FMEA template for your business in several instances. Here are some examples:

- During the design or redesign of a product, process, or service.

- When a product or service that’s already on the market needs to be applied differently.

- When investigating actual failures of current processes or products and services.

- Before creating a control plan for a new process or a modified version of it.

- When adding or improving goals on any existing product, service, or process.

- At different stages of the life of any product, service, or process (done periodically).

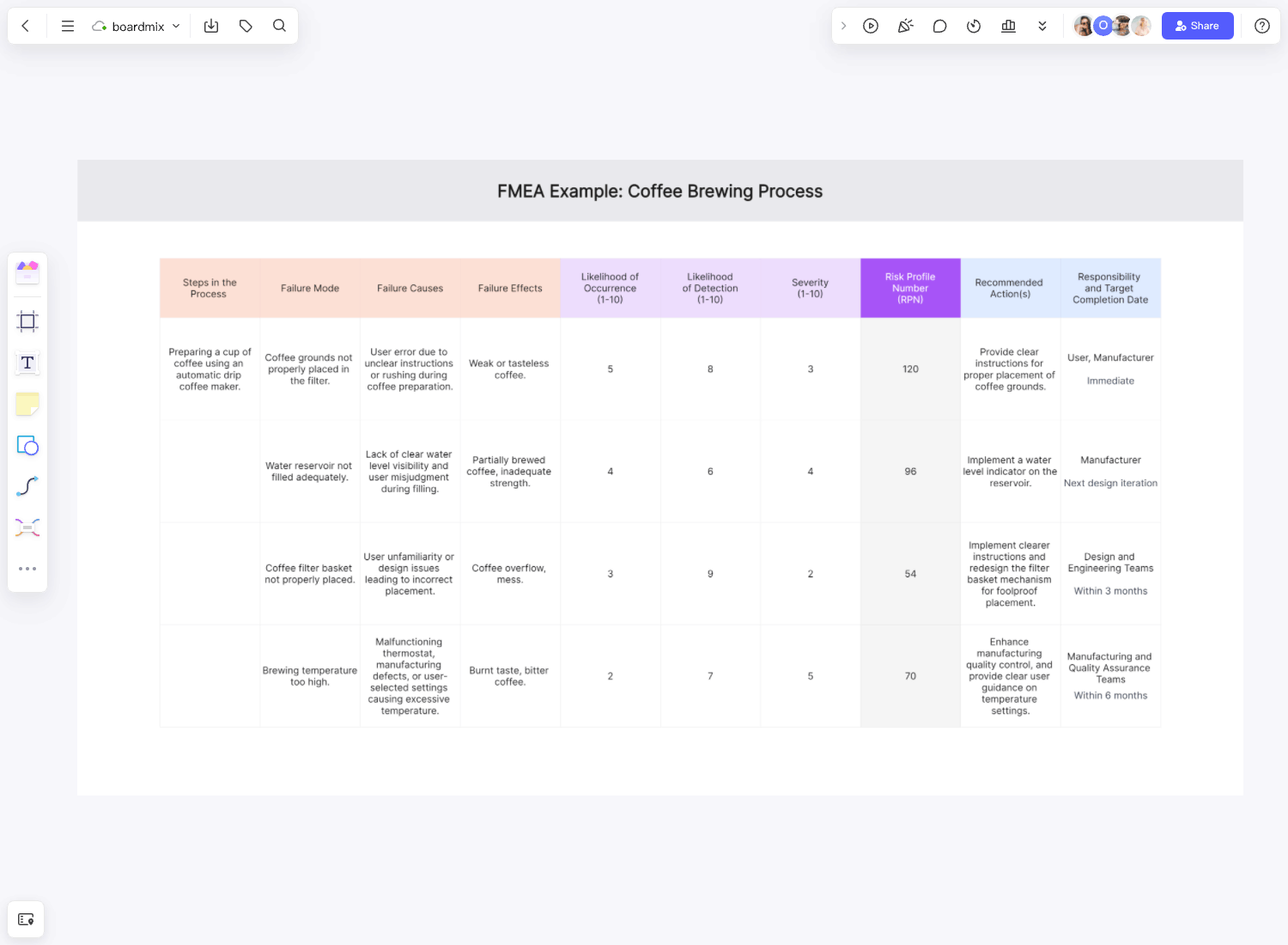

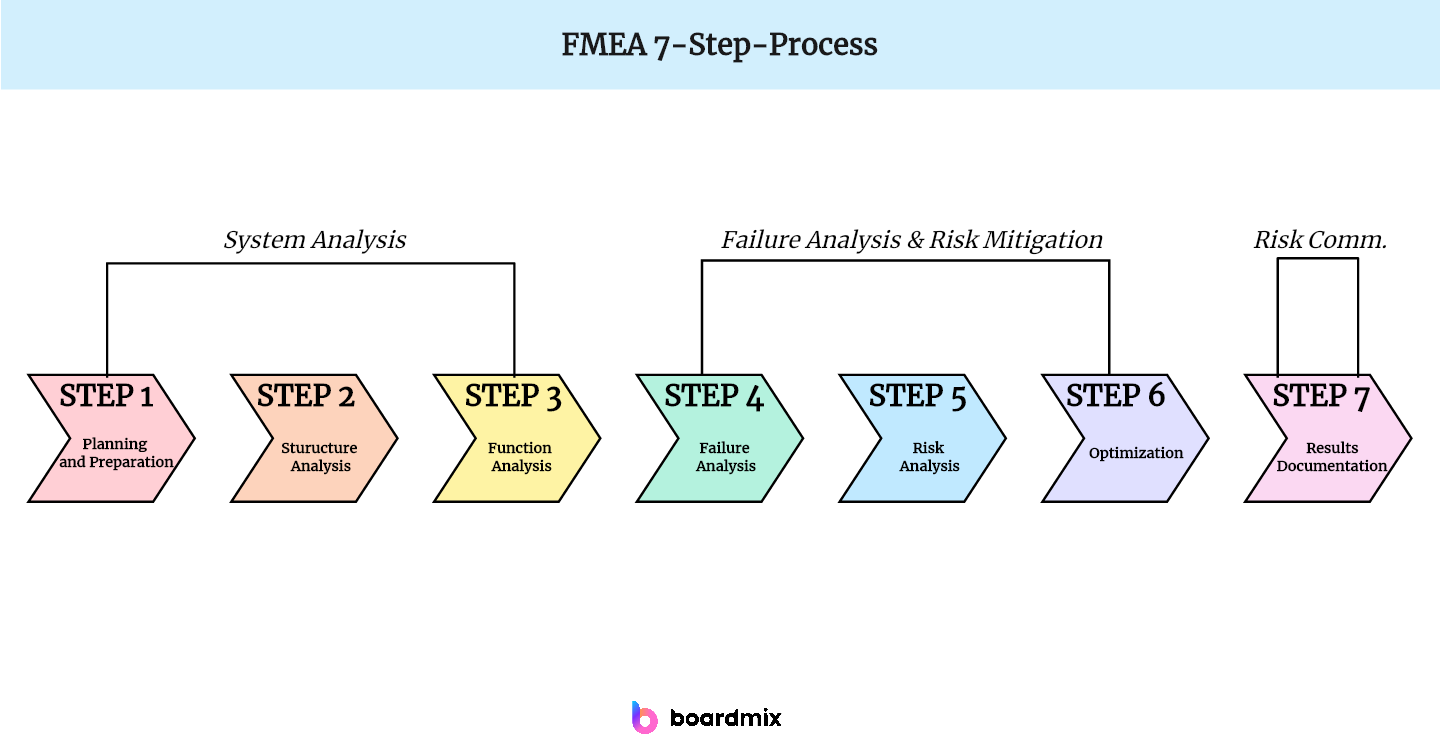

What are the steps of the FMEA process Template?

The FMEA process, also known as Failure Mode and Effects Analysis, is a structured approach used to identify and address potential problems or failures in a system or product before they occur.

The process is divided into five crucial steps.

-

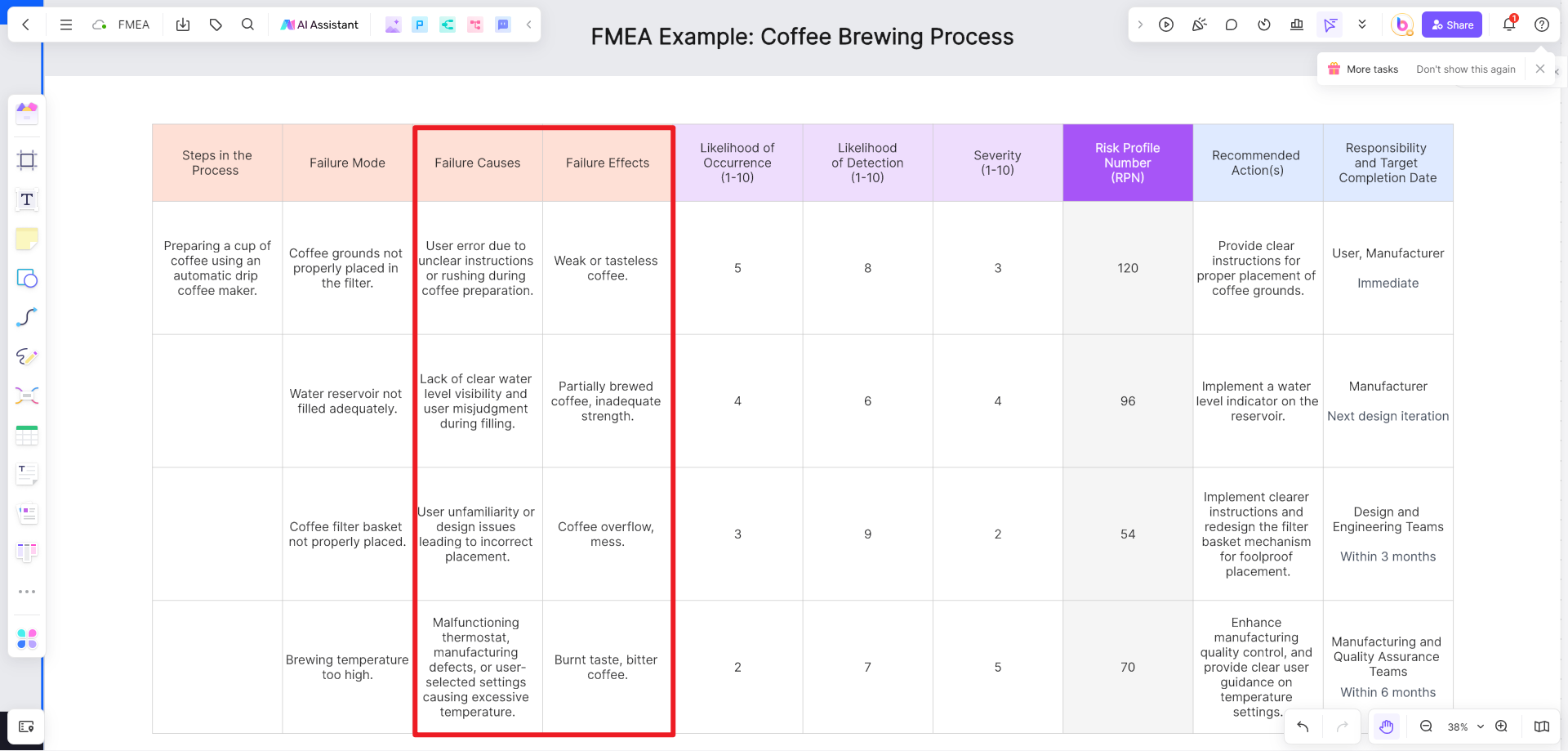

Identification: This is the first step in the FMEA process where all potential failure modes are identified. It involves a thorough understanding of the system, product, or process under review. Here, you will need to list all the components, functions, and operating conditions associated with what you're analyzing.

-

Analysis: In this step, you analyze each potential failure mode identified in the previous step. What could be the possible causes of each failure? What would be its effects? This is where you delve into understanding the root cause of each possible failure.

-

Risk Assessment: After identifying and analyzing potential failure modes, it's time to assess their risk level. Each potential failure mode is rated based on three criteria: severity (how serious the effect would be), occurrence (how frequently it might happen), and detection (how likely it is that the failure would be detected before causing harm).

-

Prioritization: With all this information at hand, you can now prioritize the risks based on their severity, occurrence, and detection ratings. This forms what's called a Risk Priority Number (RPN). The higher the RPN, the more urgent it is to address that particular risk.

-

Action & Review: The final step involves taking action on high-priority risks and reviewing their effectiveness over time. Actions might include redesigning a component, adding safety features, or improving quality control processes.

Benefits of FMEA Analysis Template

The FMEA analysis template primarily mitigates potential risks in any product or process. The outcome is to improve customer satisfaction, which enhances a company’s reputation and success. Here are some remarkable benefits of implementing an FMEA analysis for your business.

Early detection of flaws and deficiencies

Your teams can proactively find and address issues before they affect other areas of your operation. It can stump the problem early and even prevent it from happening. That way, you can also avoid costly remodeling and recalls.

Comply with legal standards

Tiny errors or discrepancies in any product or process can often cascade into many failures. Some of these issues can become a legal liability down the line. You can evade this incident by using FMEA to identify possible risks that break the law.

Enhance collaboration

An FMEA template allows every team member to foster their working relationship with one another. This analytical tool requires cross-functional collaboration, urging different departments to share their input. Thus, it improves teamwork by making sure that all areas of the business are heard.

Ensure efficient product runs

Failing in product design or any process can lead to expensive and time-consuming mistakes. When you practice FMEA, you investigate the development phases and implement preventive or corrective measures against flaws. It saves resources and time, with less rework needed in the next stages of the product run.

How to Create FMEA Template Using Boardmix

Boardmix scrum task board is simple, easy to use, and highly flexible. The following guide will help you set up a scrum task board without hurdles.

Step 1: Log in to Your Boardmix Account

To begin, you'll need to access your Boardmix account. Go to the Boardmix website and enter your login credentials. If you don't have an account yet, you can sign up for a new one for free.

Step 2: Search and Choose the FMEA Template

Once you're logged in, head over to the Template library. You can find this in the main dashboard. Please search for the fmea Template and click to use it for free.

Step 3: Customize and Edit Your FMEA Template

Now that you've chosen the template, it's time to customize it according to your needs. You can decorate your template with shapes, lines, drawing pens, icons, and other tools. The FMEA Template comes with several sections that you can fill out.

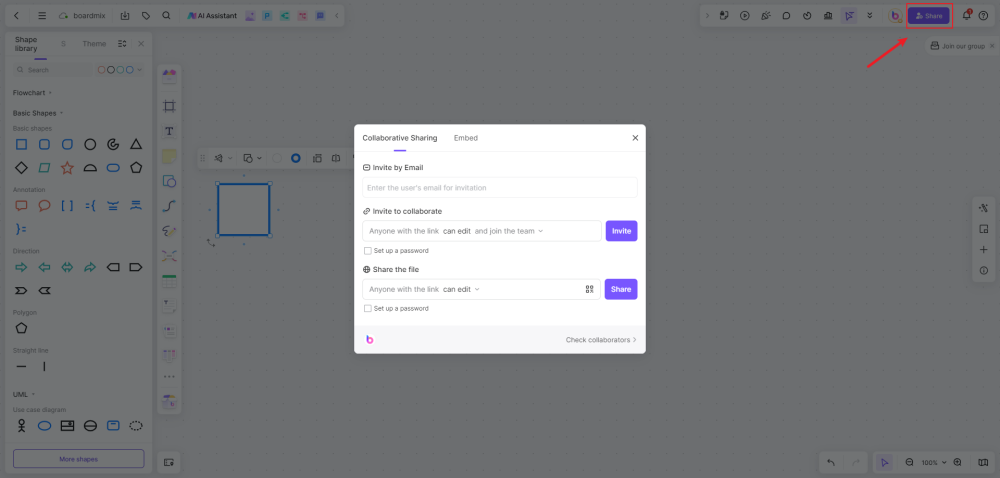

Step 4: Save Your Work, Share and Collaborate

When customizing your FMEA Template, Boardmix autosaves your progress, but it's good practice to manually save before exiting.

Next, share your FMEA template to collaborate with your team. Click on the "Share" button on the top right corner of the screen, copy the sharing link, and send it to anyone whom you want to collaborate with. People can join this file to edit and collaborate on this file in real-time by clicking this sharing link. We encourage your team to leave comments, suggest edits, or ask questions online so you can adjust it in time.

FAQs about FMEA

What are the criteria for FMEA analysis?

Generally, there are three criteria to consider when using Failure Mode and Effect Analysis:

You must identify how severe the possible consequences are for the customer.

Determine how often the issue would likely occur.

It would help if you determined ways to easily detect these problems.

What are the three types of FMEA?

The three types of FMEA include Design FMEA, which can help you pinpoint problems with the design components and stages. Process FMEA is another type, wherein it is used to analyze and maintain the objectives of process control. The third type is FMECA, or Failure Mode, Effects, and Criticality Analysis. This FMEA template utilizes quantitative methods to measure criticality.